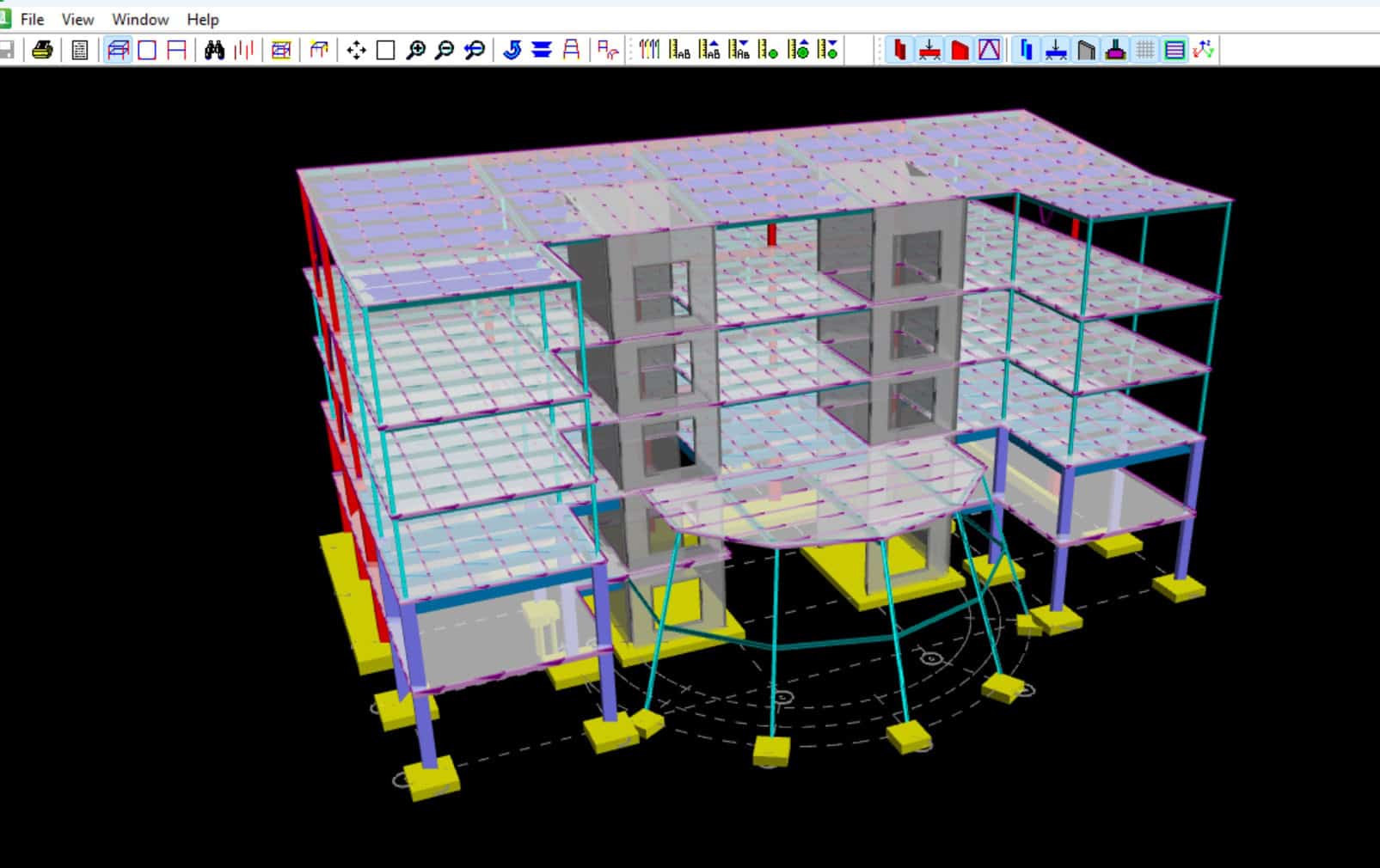

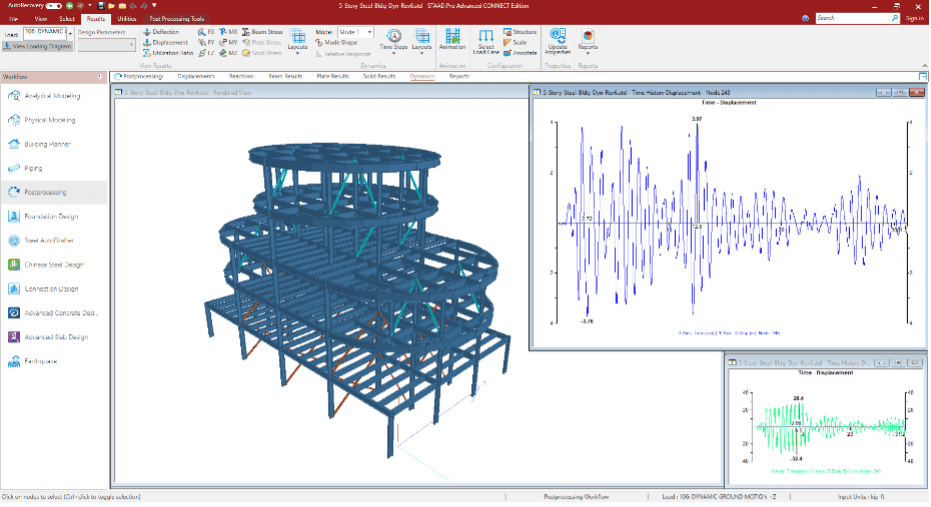

Blow molding is a process frequently used to manufacture hollow plastic objects such as bottles and tanks. A molten plastic tube (parison) is extruded into the mold and pinched at one end. Compressed air is then blown into the parison cavity, which takes the shape of the mold. As the material properties of the parison are highly temperature dependent, the heat exchange between the parison and the blown air is very important during the process. The thermal coupling capability of ADINA-FSI allows the modeling of such conjugate heat transfer effects.

The animation above depicts an axisymmetric blow molding simulation using ADINA-FSI. The parison is modeled as a temperature-dependent viscoelastic material undergoing large displacements and large strains. The internal part of the mold is modeled as a contact surface and the compressed air is injected using a time-dependent normal traction boundary condition.