The use of advanced polymers in demanding engineering applications requires correspondingly advanced material models and reliable finite element solvers. In particular, viscoelastic (time-dependent) effects can become important when polymeric components are placed into service. For example, materials such as ultra-high molecular weight polyethylene are being used in biomedical applications. Another example is polytetrafluoroethylene (PTFE), also known as “Teflon,” which is widely used in industrial sealing and bearing applications due to its low frictional properties, chemical inertness, and exceptional resistance to high temperatures, corrosion, and stress cracking. Quite often, these components will undergo severe deformations in situations involving contact, temperature effects, and other types of nonlinearities. A proper understanding of the viscoelastic behavior of these components is required.

In response to customers’ requirements, ADINA supports the Bergström-Boyce and Three-Network viscoelastic material models. These sophisticated material models allow users to capture complex viscoelastic behaviors of polymeric components. ADINA’s powerful solvers, element library, and multiphysics capabilities allow users to take full advantage of these material models.

Benchmark

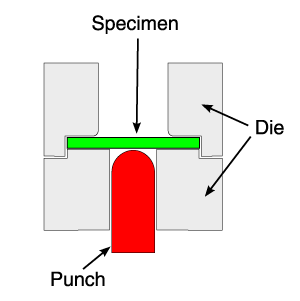

The small punch test is a standard method of characterizing materials. A disk-shaped specimen is confined within a die, and a punch is driven against the specimen. The punch is driven at 0.5mm/min and the reaction force is recorded as a function of displacement. In this case, the polymer to be tested is a high-density polyethylene. Figure 1 illustrates the experimental setup.

Figure 1: Cross-sectional schema of the small punch test. The specimen is 0.5mm thick and 6.4mm in diameter.

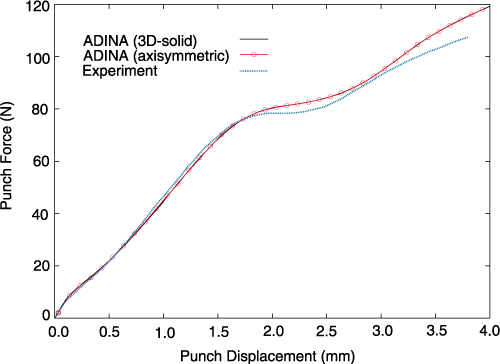

Figure 2 compares the predictions from the 3D-solid and axisymmetric analyses to the experimental results from Bergström and Bischoff [1]. ADINA’s Three-Network model was used to simulate the material during testing; material parameters were obtained from Ref. [1]. These models also include the effects of frictional contact. ADINA’s powerful, higher-order u/p elements effectively prevent volumetric and shear locking for this severe deformation.

Figure 2: Results from ADINA compared to published experimental data. The 3D-solid and axisymmetric analyses

yield essentially identical results — both closely matching experimental data.

The results demonstrate how ADINA’s implementation of the Three-Network model closely matches experimental results for polyethylene. In both the three-dimensional and axisymmetric two-dimensional cases, ADINA predicts essentially identical results which compare favorably with the experimental data. Of course, the axisymmetric model runs much more quickly, but it cannot capture any asymmetric modes that might be excited under, for example, extreme compressive stresses.

Thermal Effects

The Bergstrom-Boyce and Three-Network material models can also account for thermal effects, including expansion/contraction and temperature-dependent viscoelastic behaviors. Furthermore, viscoelastic materials are dissipative (i.e., they generate heat as they deform), and ADINA can predict the resulting internal heat generation when running a fully-coupled thermomechanical analysis.

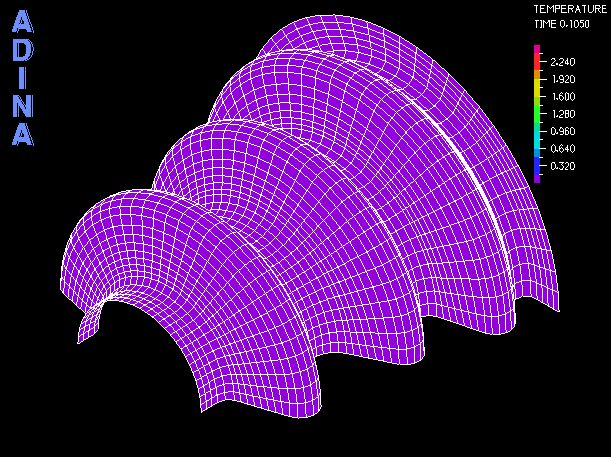

Figure 3 shows the Three-Network model being used with ADINA’s 3D-shell element to model a rubber CV-joint boot. This model includes self-contact and temperature effects in a fully-coupled thermomechanical analysis. Internal dissipations are interpreted as heat generation.

Figure 3: 3D-shell model of rubber boot using the Three-Network model to predict the heat generated by internal dissipations

Conclusion

As designs become more sophisticated, and complex material behaviors more important to overall performance, the use of appropriate material models in analysis becomes equally important. ADINA offers the analyst a library of advanced material models and state-of-the-art finite element formulations, solvers, and contact algorithms that can be reliably used with advanced material models across a range of multiphysics applications.

References

- J.S. Bergström and J.E. Bischoff, “An Advanced Thermomechanical Constitutive Model for UHMWPE,” Int. J. Struct. Changes Sol., 2:31–39, 2010.

- J.S. Bergström and M.C. Boyce, “Constitutive modeling of the large strain time–dependent behavior of elastomers,” J. Mech. Phys. Solids, 46:931–954, 1998.

Keywords:

Bergström-Boyce, Three-Network Model, viscoelasticity, advanced polymers, thermal coupling, large strains, multiphysics, contact, polyethylene, Teflon