The problem of analyzing and designing deep foundations is relevant to many civil engineering structures, because we are commonly and frequently constructing buildings on soft soils. Pile foundation is a popular type of deep foundation technique used to transfer superstructure load into subsoil and bearing layers. In this context, the accurate prediction of piles’ settlement and proper evaluation of pile bearing capacity is a fundamental aspect of deep foundation design. This could be a challenging task for the designer in the case of complex pile-soil interaction or in situations involving a consolidation process.

Pile modeling is primarily a 3D problem

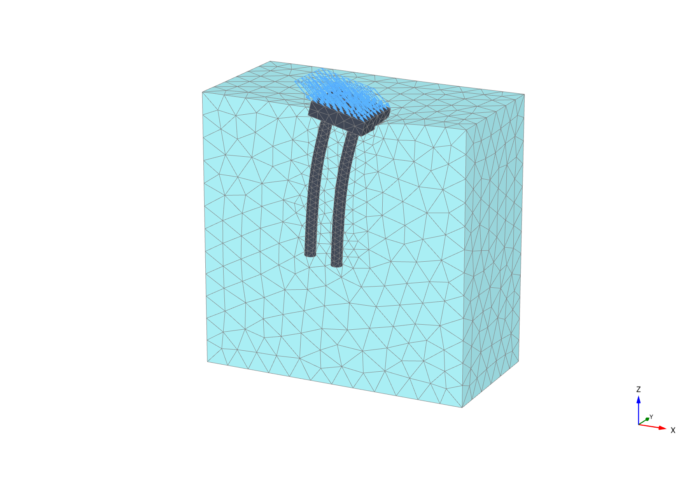

Due to the 3D nature of the pile geometry and the possible lateral component of the design load, most pile foundation analyses should be set up in PLAXIS 3D. Ideally, the piles themselves will be represented by volume elements. This will guarantee the most accurate representation of the physical problem, especially regarding soil-structure interaction.

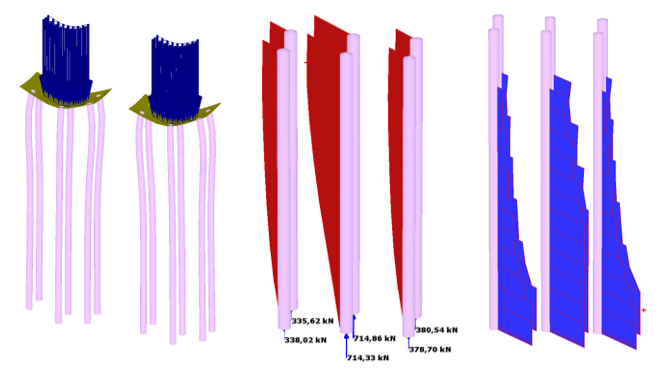

Figure 1: 3D model of a simple pile raft

With such 3D models, the piles are physically modeled, and the soil-structure interaction is accounted for by means of surface interface elements with associated Coulomb-friction behavior. Piles results will be primarily provided in terms of stresses which could later be integrated into structural forces into the PLAXIS Output post-processing environment, either:

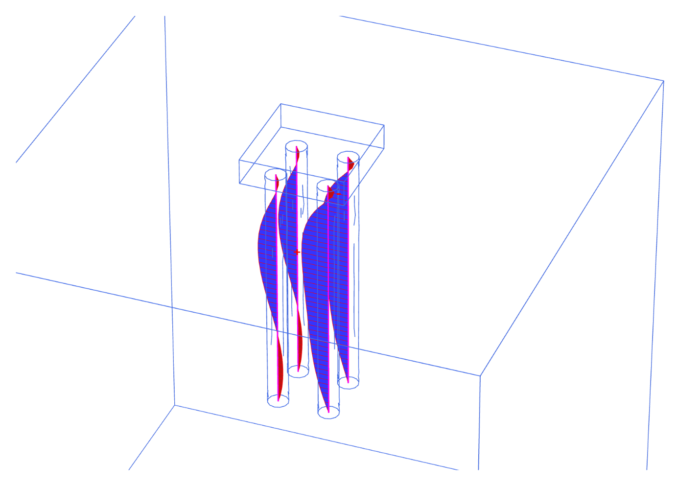

- Through direct integration of stress through the Structural Forces in Volume Piles tool, or

- By introducing low stiffness beam elements along the neutral axis of the volume piles, the purpose of which being to monitor the evolution of strains and change of curvature along them and easily retrieve the structural forces based on beam theory.

Figure 2: Bending moment in simple pile raft model

The volume approach also requires the use of relatively small elements implicitly induced by the relatively large slenderness of the pile element itself and, as a result, large number of elements. This approach may find some limitations. A large number of piles would have to be considered and the increasing number of elements (as the number of piles to be modeled increased) might become simply impractical at some point.

Piles as embedded beams, or how to efficiently deal with many piles

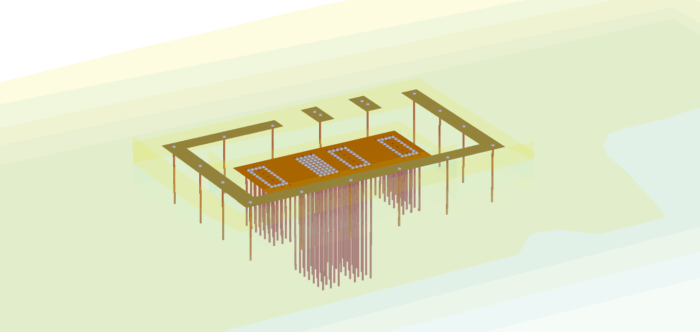

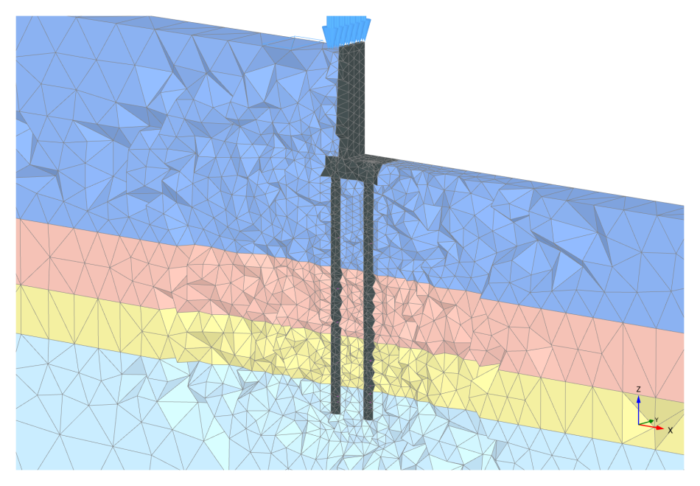

The embedded beam is a special feature in PLAXIS 3D. This feature was developed to simulate the behavior of piles in a simplified way. The embedded beam is particularly useful in cases of large numbers of piles to be accounted for in a PLAXIS 3D model. In this approach, the pile is represented by beam elements, while soil–pile interaction along the pile shaft and at the pile tip is described by special interface elements that are constructed based on node-to-node, non-linear coupling springs.

The generation of linear beam elements gives the opportunity to simulate piles as structural elements with specified material properties. This saves a large number of elements needed in the process, compared to volume piles being filled with tetrahedra elements. Another clear advantage of using PLAXIS embedded beam elements is that the generation of the coupling springs (for soil–pile interaction) does not require mesh node connectivity between the lines supporting the pile/beam elements and the surrounding soil volume. Both pile lines and soil volume could be meshed independently. The PLAXIS 3D calculation kernel automatically takes care of finding intersection loci between beam pile element and soil element faces, introducing at these points so-called “virtual” nodes where relative displacement between soil mesh nodes and pile nodes can be computed. The simplification of both the geometry description and the meshing process enables the consideration of hundreds of piles without any difficulty.

Figure 3: The use of 3D embedded beam for modeling many piles

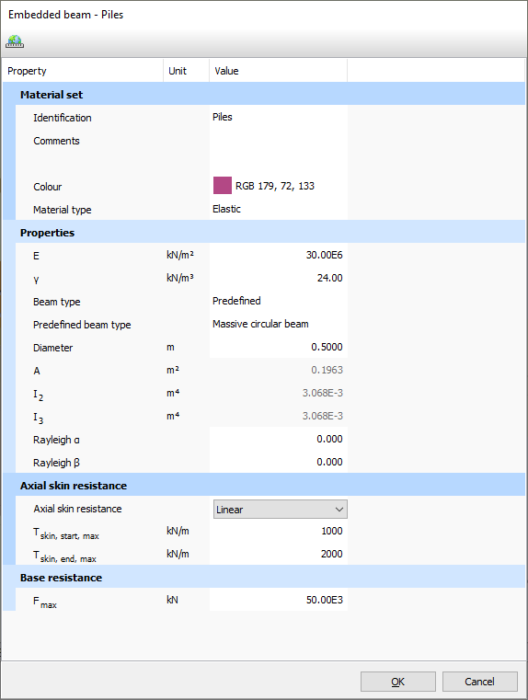

Embedded beam user input is divided into:

- Beam properties for the pile: Material stiffness and weight along with cross section shape and dimensions

- Coupling spring properties: Interface normal stresses will always remain elastic (they are not limited by any failure law), while the value of shear stress is limited by the ultimate traction value Tmax which is provided by the user along the pile shaft. Pile foot resistance is defined in a similar way, with a linear elastic-perfectly plastic spring in pile axial direction where the base force is limited with value Fmax also provided as a user input.

Figure 4: Property definition of 3D embedded beam for pile modeling

Results provided by embedded beams contain:

- Displacements

- Structural forces in the beam: Bending moments and axial forces

- Interface results in terms of shaft friction (absolute and relative) and foot force

Embedded beam elements have demonstrated particularly good results for serviceability states of pile groups under axial loading. It is important to note that the calculation time and the number of elements required to analyze a certain pile–soil interaction problem are sufficiently reduced by using embedded piles compared to using volume piles.

Figure 5: Available results for embedded beams in PLAXIS 3D

And what about 2D?

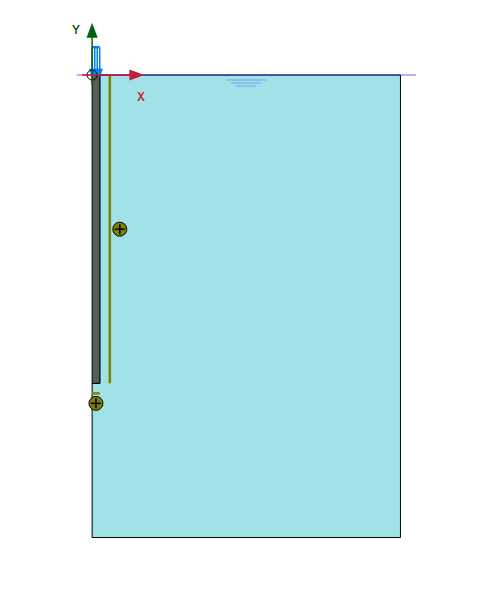

In the framework of a PLAXIS 2D analysis, it is possible to analyze axially loaded piles by assuming axisymmetric conditions. Such models are very cost-effective, computationally speaking, but can only be used in the case of axial loading, as any consideration of lateral loading would not fulfill the axisymmetric conditions and would therefore require a proper 3D model.

Figure 6: Axisymmetric model of an axially loaded pile in PLAXIS 2D

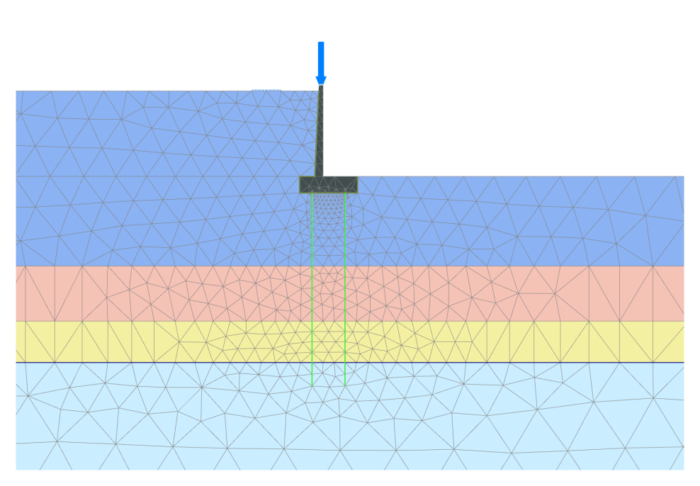

The embedded beam feature presented earlier is also available for 2D plane strain situations but can only be used for the analysis of pile rows (rows extending in the out-of-modeling-plane direction). The 2D nature of the plane strain analysis does not allow for the consideration of a singular buried entity (that could only be considered in a 3D model). Thus, it implicitly requires that any 2D embedded beam would represent a continuously spaced set of piles in the out-of-plane direction with a pile-to-pile spacing value not too large compared to the pile diameter, such that an average soil displacement as provided by the 2D soil mesh between piles would remain an acceptable assumption.

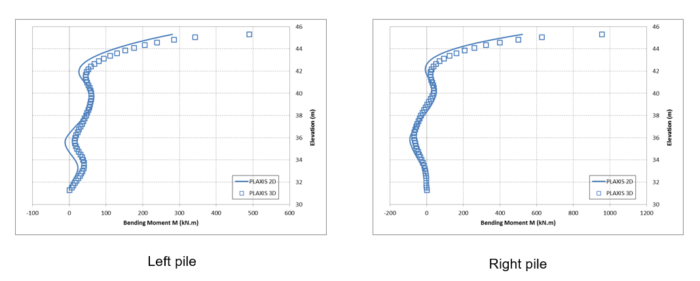

When the assumption of continuously spaced piles is satisfied, the PLAXIS 2D model shows very good agreement with equivalent 3D models, but at a fraction of the computational cost.

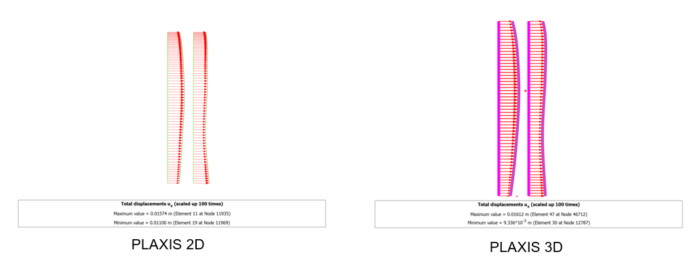

PLAXIS 2D with embedded beam row

PLAXIS 3D with volume pile

Figure 8: Pile model in PLAXIS 2D versus pile model in PLAXIS 3D

(a) Lateral displacement

b) Bending moment

Figure 9: Pile model comparison – PLAXIS 2D versus PLAXIS 3D

Learn more about this event here.

Discover the PLAXIS Productivity Strategies series featuring blogs, LinkedIn Live sessions, and webinars.

Learn the top efficiency tips to solve your common problems.

LEARN MORE ABOUT PLAXIS WITH VIRTUOSITY:

Check out the Concept to Construction series including the PLAXIS session here.

Interested in PLAXIS soil models? Find more resources here.

Want to learn the specialized material models in PLAXIS 2D and 3D?

Get access to new educational PLAXIS videos to explore the benefits and value of using PLAXIS.

For the price and the amount of Keys included in Concept to Construction Virtuoso Subscription, please visit this page.

Want to learn more about what PLAXIS can do for you? Don’t hesitate to contact our geotechnical experts. We are happy to help.