Beyond digital models: The digital twin paradigm shift

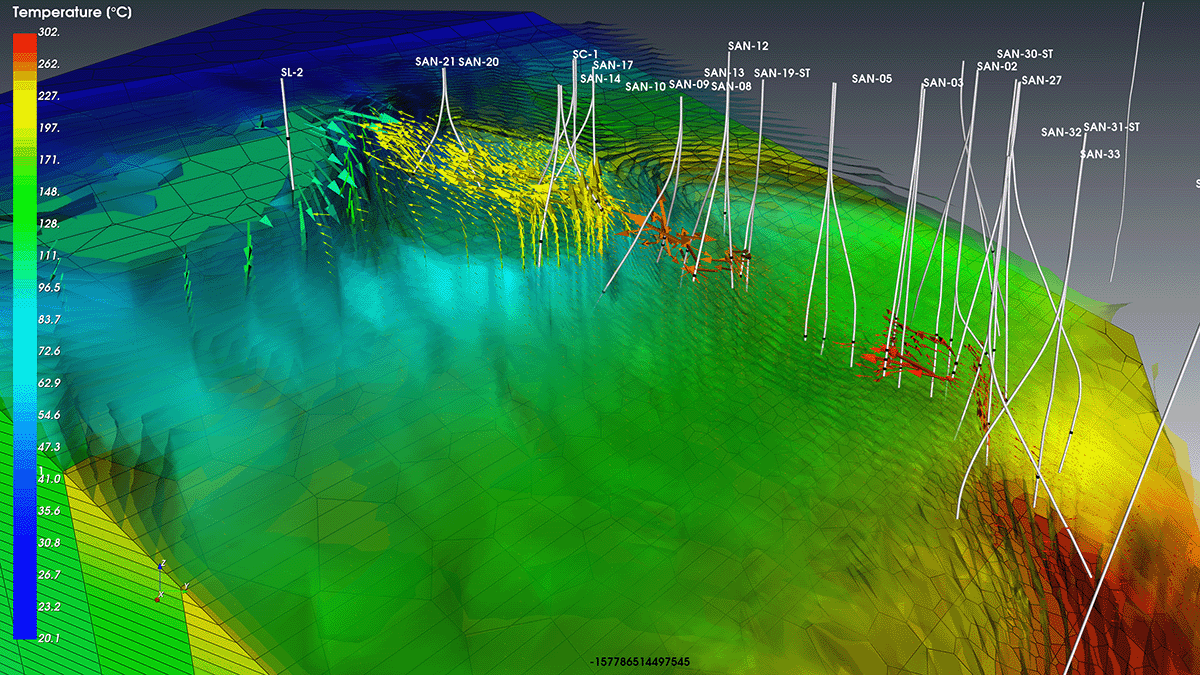

Digital twins have revolutionized projects in engineering circles for years, but its application to the subsurface realm represents a new way of thinking. The best way to understand the underground isn’t as a static model of what lies beneath—it should be a living, dynamic representation that evolves as new data emerges and as our understanding deepens.

The multidiscipline digital approach initiates a conversation between these disciplines, between data and interpretation, between what we know and what we’re learning. It’s this conversation that marks the true paradigm shift.

Italy’s underground renaissance: A transformative implementation

To begin to understand the practical impact of this shift, consider Italy’s aging tunnel network—a vast, 2,500-kilometer underground arterial system built primarily in the 1960s and 1970s. These tunnels, critical to the country’s transportation infrastructure, face mounting challenges from decades of use and evolving safety standards.

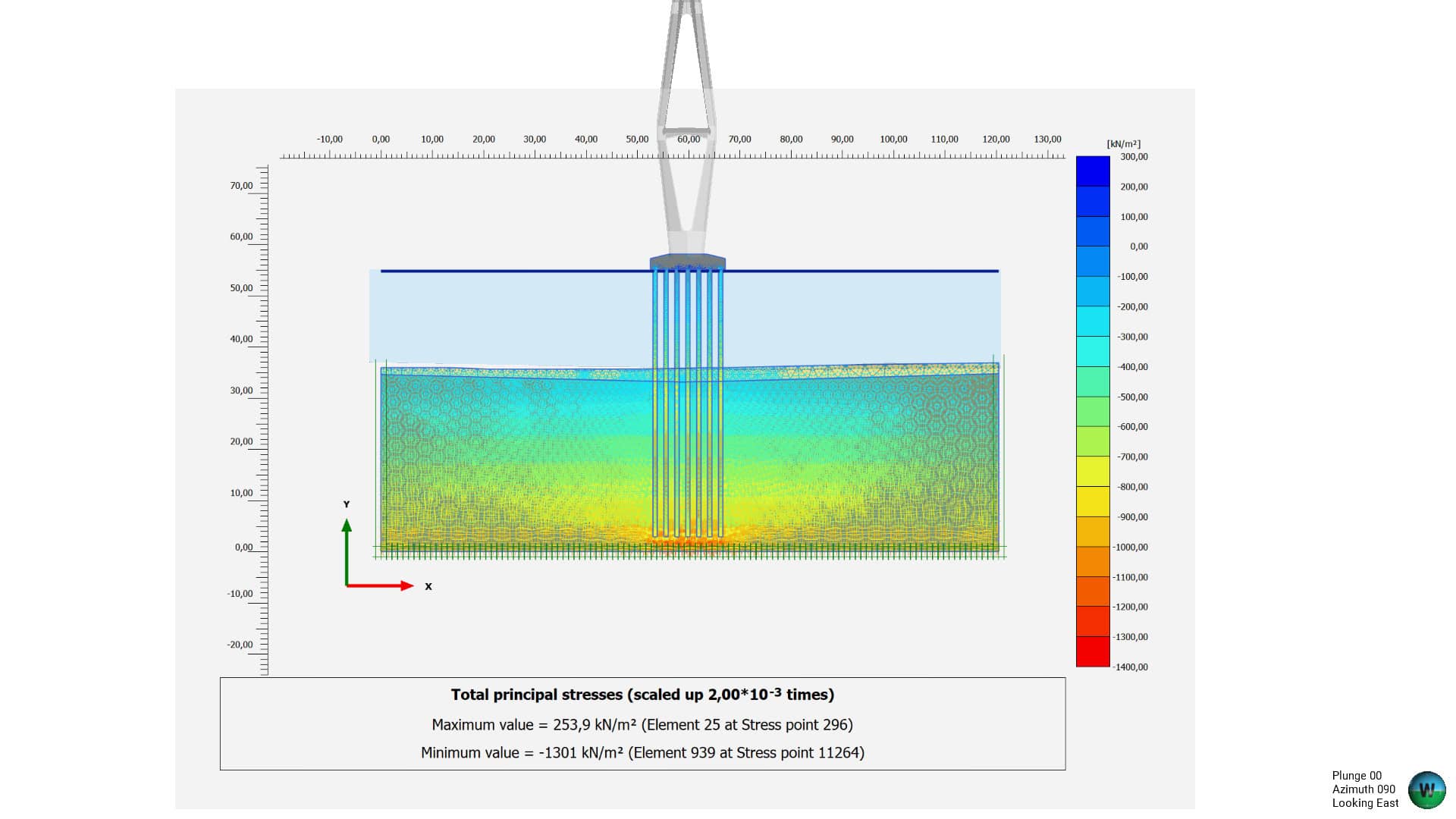

Tecne Systra took on this challenge by reimagining how tunnel assessment and rehabilitation could work in a digital age. Their approach didn’t simply digitize existing processes, it fundamentally transformed them. The reimagined workflow begins not with disciplinary handoffs, but with integrated data collection. Borehole TV cameras, flat jacks, core drilling, and other investigative tools feed into a digital twin—a unified digital environment where geologists, engineers, and designers work from the same evolving understanding of subsurface conditions.

The results are impressive: the workflow reduced modeling time by 25%, accelerated project delivery by 21.5%, improved the interpretation of survey data by 30%, and cut clash detection time by 30%.

Beyond these metrics lies a more significant transformation: the integration of survey data into a continuous digital thread that extends from initial investigation through design, construction, and into the operational life of these tunnels.

Ana Emiliano dos Reis, who lead BIM implementation at Tecne Systra during this project, noted how this approach changed their fundamental relationship with subsurface data: “Going digital transformed how we integrate and evaluate survey data, giving us entirely new capabilities to support design decisions.”

Read the case study here.

While cost and time savings make compelling headlines, the most profound benefits of digital twins may be those that never appear in project reports because they represent problems avoided rather than problems solved.

Managing ground risk with digital twins

Traditional approaches to ground risk management have relied heavily on contractual mechanisms to allocate risk. Interdisciplinary collaboration offers something more valuable: the conversion of “unknown unknowns” into “known uncertainties.”

This distinction matters enormously. When project teams can visualize areas of geological complexity or uncertainty, they can make targeted investments in additional investigation rather than apply broad risk premiums. They can develop focused mitigation strategies rather than generalized contingencies.

As Pat McLarin, who leads the strategy for civil infrastructure at Seequent, the Bentley Subsurface Company observes, “The digital twin can indicate areas of expected bad ground or where the ground conditions are unclear in the context of an engineering design.” This contextual understanding transforms how teams approach risk—not as something to be contractually transferred but as something to be collaboratively managed.

Engineering a lower carbon footprint

The environmental impact of tunnel construction extends far beyond the immediate project footprint. Material extraction, processing, transportation, and disposal create significant carbon footprints. The ability to optimize excavation and material reuse represents a substantial but often overlooked sustainability opportunity.

When engineers can simulate ground behavior with greater fidelity, they can design more efficient support systems, optimize excavation profiles, and develop targeted ground improvement strategies. Each refinement reduces material requirements and energy consumption.

If we can optimize the amount of earth we move and the reuse of material, then we can be more sustainable. This isn't sustainability as a marketing tagline—it's sustainability through precision engineering.

Pat McLarin

Collective intelligence amplification

Perhaps the most powerful benefit of a digital twin is the least quantifiable: its ability to enhance collective intelligence across project teams and stakeholders. When geologists, geotechnical engineers, tunnel designers, and construction specialists share a common digital environment, something remarkable happens. Disciplinary boundaries begin to blur. Questions become more sophisticated. Insights emerge from unexpected connections.

“When everyone can really understand what’s going on in the subsurface, that leads to better decision making,” McLarin observes. This shared understanding transforms not just what teams decide, but how they make decisions—with more inputs, broader perspectives, and deeper consideration of interdependencies.”

Stay tuned for part three to learn the practical strategies for implementing these transformative approaches in your organization.

Learn more about OpenTunnel Designer and the Bentley software used by Tecne Systra. And be sure to read the previous blog post in our series.