While most structural analysis software can evaluate everyday stresses, they often fail to prepare buildings for extreme events. As environmental disasters and severe weather become more frequent, clients demand greater confidence in building safety.

Engineers need better tools to ensure their designs can withstand these challenges.

Buildings live complicated lives. The day any large piece of infrastructure is completed is the day it also opens itself to the unknown.

Unpredictable events, from fires and floods to earthquakes and explosions, will fiercely test the structure—perhaps well beyond the questions asked of it in the original design.

According to the United Nations, climate-related disasters in 2020 caused more than 15,000 deaths with 98 million people affected, plus an economic cost of $171bn.* In 2023 there were a total of 399 natural disasters, with the UN Office for the Coordination of Humanitarian Affairs noting that economic losses had now topped the $200bn mark.**

For buildings to survive and protect the lives of the people using, working, or living within them requires an extra level of resilience; an inner ‘toughness’ that can be difficult to assess using most structural analysis software.

While most such software is equipped to meet prescriptive design codes requirements—the everyday stresses and strains—they are less well-equipped to predict the results of an extreme event. However, advanced finite element analysis software can offer solutions to assess the actual performance of structures under a range of extreme conditions.

By predicting the response of structures to extreme events, advanced finite element analysis can bring a level of confidence to the design, surpassing the reliability of other structural analysis software.

It can establish a building’s ‘character under stress’ and know if it has the ability to resist the unpredictable event and remain standing. Perhaps with damage, but importantly, still safe once the event is over, or the external forces are removed.

Complex problems require a more perceptive analysis

The world of civil structures is averse to risk and uncertainty. Today, the clients of engineering consultancies and contractors in the construction or energy sectors are increasingly demanding higher levels of confidence, precision, certainty, and optimization.

However, if the resulting calculations are basic and unable to explore unexpected stresses in detail, these assumptions can lead to conservative and overdesigned structures. That, in turn, can increase costs (and potentially the carbon footprint), which a more perceptive analysis of the risks might have avoided.

In response, major engineering and construction businesses are applying advanced finite element analysis (FEA) applications to yield those insights and remain competitive.

But such applications may still not offer them the critical event predictions that more advanced analysis can supply. They have some FEA capabilities, but not enough to tackle the challenging calculations that come with intricate loadings, complex geologies, and material properties.

By enhancing their analysis armoury with advanced finite element tools, engineering firms can produce models of their designs and structures that are closer to the realities of a critical event, and provide the increased confidence, accuracy, certainty, and economy required .

From blast to earthquake, each event presents its own challenges

So how does it work? There are various ways that an engineer could assess a structure for safety against a blast. A simple route would be to convert the pressure wave from the blast wave into forces that are directly applied to structural members. This works, but it’s a simplified and less thorough answer that could result in expensive and overdesigned structures.

In reality, the pressure wave front of a blast is short duration. If the components of the structure are flexible, they can dissipate that energy, resulting in a building that is safe and more cost effective. But how can you gauge the level of flexibility required?

Or you might be operating in a region of high seismic activity where the structure, its components, and the connections between them, may be subject to stresses beyond their design limits. You still need to be certain that your chosen design can withstand these atypical extremes. How can you ensure you are complying with that region’s safety regulations?

In both cases, it’s easier to reach a satisfactory and confident conclusion with software expressly designed to handle this specialist level of dynamic nonlinear analysis.

How ADINA can help

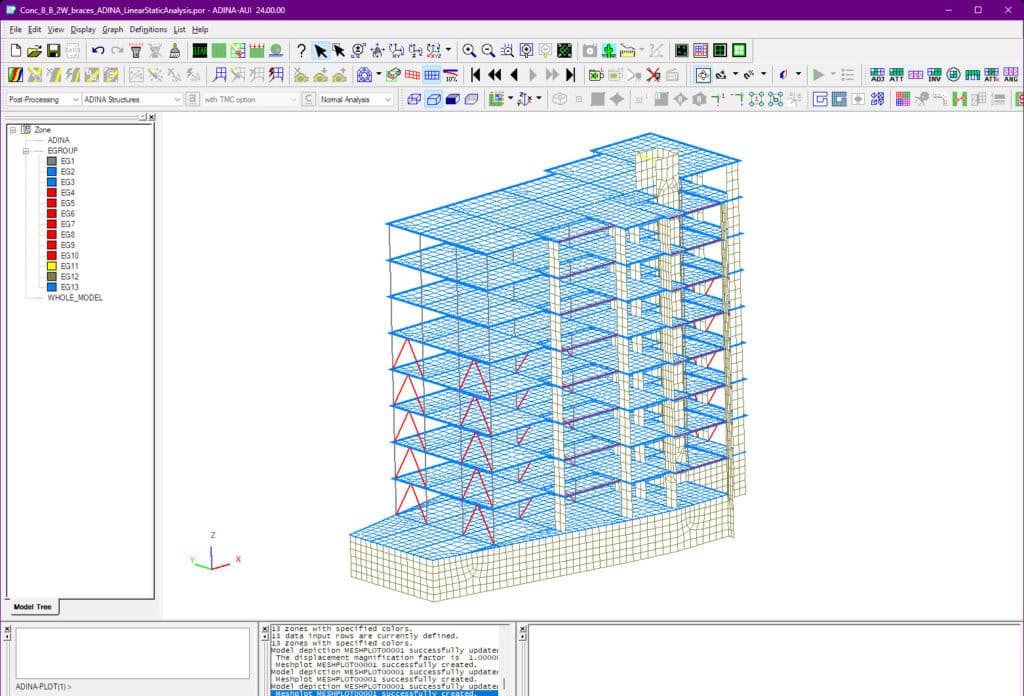

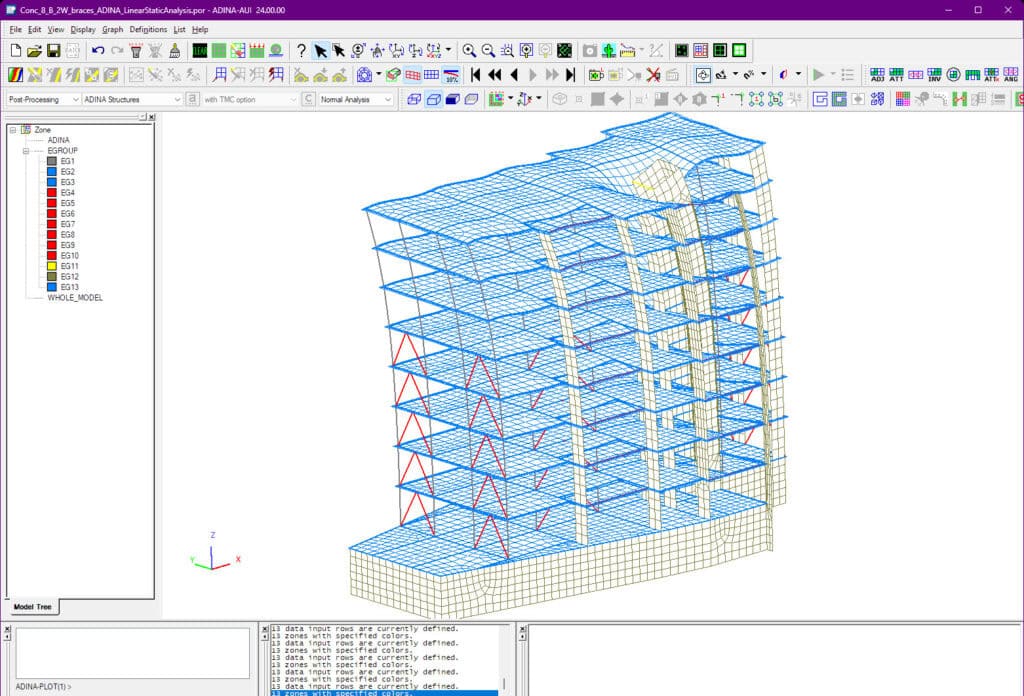

ADINA is Bentley’s advanced finite element analysis software, specifically created for dynamic nonlinear analysis of structures under extreme loads – however complex they may be.

By incorporating ADINA into their existing Bentley structural solutions portfolio, engineers can make this process seamless and bring together the best from both the design and analysis worlds. (For example, using ADINA in tandem with STAAD or RAM). This complete ‘one vendor’ solution reduces the risk of data loss between products, and helps avoid the data entry errors that can arise within material properties or unit conversions when there is a lack of software interoperability.

ADINA is particularly adept at delivering heightened accuracy where there is extra complexity.

-

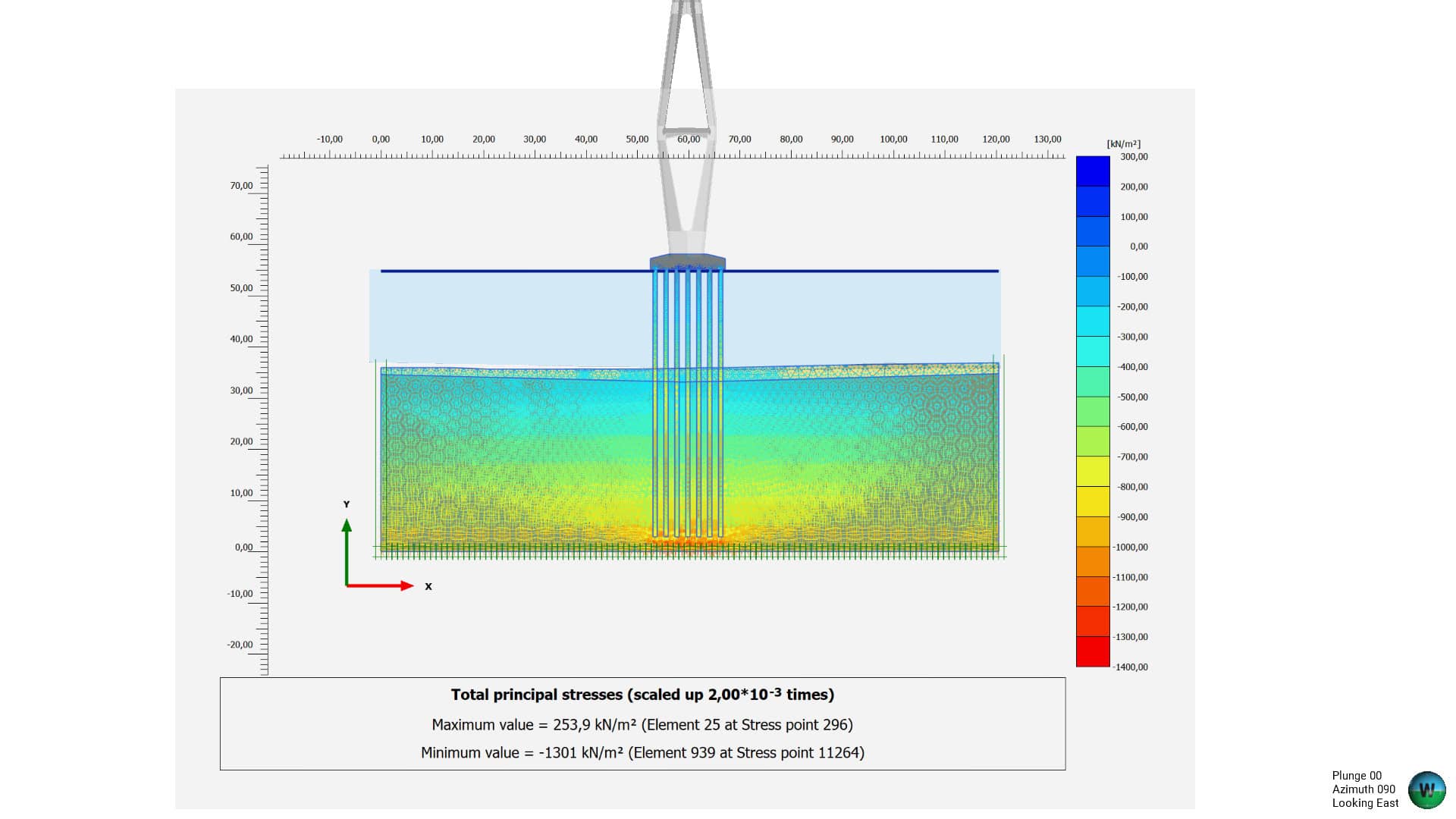

- It has powerful capabilities in place for meshing solids and giving clear analysis, even when there is an interaction between the structure and a fluid or friction contact. This could be the complicated and interweaved loads of a dam or the effects of a flood or hurricane.

-

- It can simulate heat transfer through high-temperature and high-pressure industrial piping systems.

-

- It can be used to assess an unusual condition for safety and compliance.

-

- ADINA’s evaluations can help to reduce repair or reconstruction time on unbuilt and existing structures.

Predicting the unpredictable

Buildings, bridges, stadiums, tunnels, pressure vessels and dams all carry a responsibility within their design and construction. They must stay safe, keep working, and protect the people within them, even in the worst-case scenarios.

It’s not possible to foretell when they might happen, but with advanced finite element analysis it is possible to know, with confidence, what that structure’s response will be, and to ensure that it can stand its ground against the unpredictable and the extreme.

* https://www.undrr.org/publication/2020-non-covid-year-disasters

** https://reliefweb.int/report/world/2023-disasters-numbers

ADINA’s abilities in detail

- Providing comprehensive advanced analysis solutions that account for nonlinear material and geometric effects, helping engineers design resilient and safe structures.

- Gauging the behaviour and strength of any structure or structural member in compression (buckling), with no limitation to its shape and size.

- Evaluating intended or accidental collapse of structures; to better calculate alternative load paths or predict the final collapsed state of structures for the safety of personnel on-site, and surrounding assets.

- Reducing or eliminating the need for expensive physical testing, such as wind tunnels, or mechanical tests of a structure component by performing computer simulation.

- Undertaking thermal and thermo-structural analysis of structures such as early-age thermal cracking of concrete. (Offers the potential of significant savings in steel rebar, particularly for large, thick concrete pours when compared to using codes of design).

- In general, to model, analyse, and design structures and components which are outside the codes of design because of their geometry or behaviour.

- Structural assessment of existing structures, whether damaged or not.

- Providing CFD/FSI simulation capabilities for analyzing structures interacting with wind or fluids.

- Engineering studies requiring advanced analysis approaches, including but not limited to human-structure interaction dynamic studies, soil structure interaction, high speed infrastructure bridge dynamics or track structure interaction, short circuit events in substations, and preloaded bolted connections.

- Predicting high and low-cycle fatigue of metallic structural components.

- Incorporating the effect of fluids, such as in liquid-filled tanks, grounded or elevated, subject to static or dynamic events. Particularly for cases not accurately handled by the existing codes of design.

- “Design by analysis” in existing codes of design and technical reports, such as ASME, for pressurised components.

- Carrying out advanced analysis of materials such as rubbers and other hyper-elastic materials, wood, cast-iron and some geotechnical models among many others.