The Challenge in Consolidation Analysis

Construction of embankments on soft soil presents a challenge. Soft soil deposits have a high moisture content and a low permeability by nature. Furthermore, their behavior strongly depends on the rate of loading / unloading. Subjected to a quickly applied surcharge – like the construction of an embankment – all related stress change will initially be transferred to the water trapped in the soil’s pores. As water needs time to flow out from pores of soil with low permeability, we initially encounter an increase in pore water pressure, leading to a decrease of effective stresses and shear resistance. In geotechnical terminology we are dealing with undrained behaviour. What’s the consequence? The safety of the embankment is at risk.

To overcome this challenge, intermediate consolidation periods must be adopted for the excess pore pressure to dissipate and shear resistance in the soft soil to increase.

This means that, to design an embankment on soft soil, a geotechnical engineer must determine

- the maximum excess pore pressure generated in the soft soil,

- how long it takes for the soft soil to consolidate and excess pore pressure to dissipate to safe values, and

- the factor of safety along the consolidation process.

Consolidation Analysis Made Simple

Finite element analysis (sometimes referred to as FEA) can be used to determine these necessary factors. Here we break down the basic workflow to use the finite element method (FEM) for consolidation analysis of embankments.

For a consolidation and safety analysis of an embankment on soft soil, the required inputs are as follows:

- Soil stratigraphy and groundwater level

- Embankment geometry

- Construction stages over time

- Stiffness, resistance and flow parameters of the materials involved

These parameters vary according to the constitutive model adopted for each material. For example, using the Mohr-Coulomb model, Young’s Modulus and Poisson Ratio would describe soil stiffness, Cohesion and Friction Angle would describe resistance, and Saturated Permeability would be used as a flow parameter.

The workflow to perform your finite element analysis would follow these steps:

- Define the soil stratigraphy

- Draw the structures related to the geotechnical project

- Create the finite element mesh

- Define the flow conditions

- Set the staged construction phases

After these steps are completed, the geotechnical analysis can be performed. Each construction phase is calculated separately, in sequence.

Breakdown: Example Analysis

As an example, we’ll consider a 13 ft (4 m) high embankment with a 52 ft (16 m) wide crest built on top of soft soil.

- The lateral slopes are 1V:3H.

- The soft soil is composed of a 10 ft (3 m) deep Peat layer on top of 10 ft (3 m) of clay.

- Below the two layers of soft soil, there is dense sand.

To model this geotechnical problem, we can take advantage of the symmetry and model only half of the embankment.

The phases of the staged construction are set as follows:

Starting point: Generation of initial stresses at the site, prior to the construction of the embankment. Due to the horizontal surface and the horizontal layering, the K0 procedure can be used for this

First phase: Construction of the bottom 7 ft (2 m) of the embankment in two days

Second phase: 30 day-long consolidation

Third phase: Construction of the top 7 ft (2 m) of the embankment in one day

Fourth phase: Consolidation until a pre-defined maximum excess pore pressure is reached

Safety analysis: To verify the Factor of Safety of each of the above phases, four new calculation phases are created, starting from each of the consolidation phases. Safety analysis in PLAXIS uses a so-called phi/c reduction method in which the strength of the soil materials will be reduced with a factor until either failure is reached or the maximum number of calculation steps is reached.

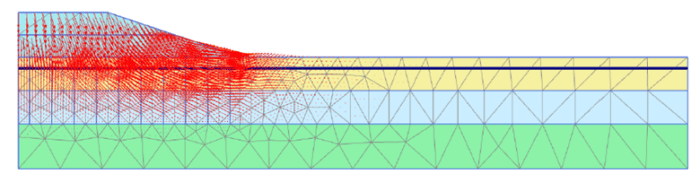

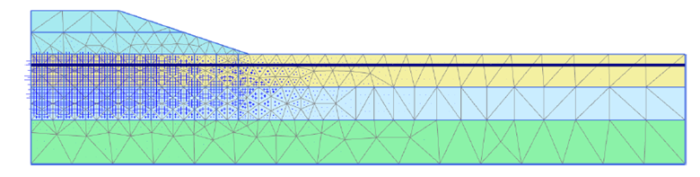

The output of the analysis is, for each construction stage, the resulting strains, displacements, stresses, and pore pressures within the soil. The values of displacement that occur at each consolidation phase can be seen: the formation of the sliding mechanism at the embankment slope and the values and location of excess pore pressure generated due to the raising of the embankment.

Displacement increments after undrained construction of embankment

Excess pore pressures after undrained construction of embankment

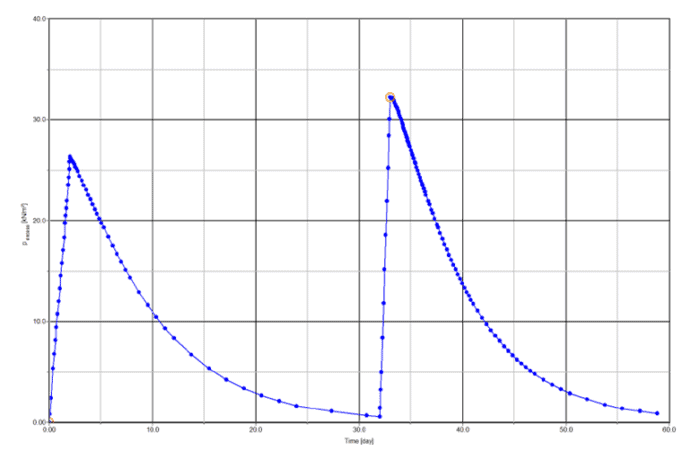

Graphs can be drawn to show the evolution of this data over time. For example, they can show how the excess pore pressure develops along time in pre-selected points of the soft soil and the displacement along time of pre-selected points of the embankment surface. The Factor of Safety of the strength reduction analyses can also be obtained.

Development of excess pore pressure under the embankment

With finite element analysis, the generation of excess pore pressure in the soft soil foundation, how long it takes for the excess pore pressure to dissipate, and the Factor of Safety against slope failure can be evaluated. This geotechnical analysis allows the definition of appropriate slope inclinations and length of consolidation periods to comply with the required safety standards for your project.

Want to see an example in action? Watch the recording of our Level up Your Geotechnical Workflow webinar, available on demand.