Hyundai Engineering’s STAAD-Driven Automation for Modular and Precast Structures

Organization: Hyundai Engineering

Project Name: Design Automation System for Modular Transport and Precast Concrete Structures

Location: Seoul, South Korea

Project Phase: Ongoing digital transformation

Expected Completion Date: Currently in active deployment across projects

Estimated Project Cost: Not specified (achieves annual savings of over KRW 750 million)

Bentley Software: STAAD.Pro (with OpenSTAAD API and Command Editor)

Additional Context: Hyundai Engineering developed two in-house STAAD-powered automation systems to analyze module transport safety and automate precast concrete design, cutting analysis and review times by up to 80%, eliminating outsourcing costs exceeding KRW 750 million annually, and enabling faster feasibility evaluation during competitive bidding.

Project

When Hyundai Engineering began work on a major plant project in Seoul, South Korea, they faced a familiar challenge: traditional construction methods were too slow and expensive for the scale and complexity of modern industrial plants. Previously, Hyundai outsourced complex analyses for module transportation and precast concrete design, which cost over KRW 100 million per project and delayed early planning. This process made it difficult to quickly assess design feasibility, especially during competitive bidding phases.

To solve this issue, Hyundai turned to automation and smart software, developing two custom in-house systems: one to plan the safe transport of massive factory-built modules by land or sea, and another to automate the design of the precast concrete components, which are manufactured off-site and assembled on-site. With these in-house tools, Hyundai can now complete designs quickly and accurately—even during early bidding stages when speed matters most.

Facts

- Eliminated outsourcing costs, saving over KRW 750 million annually (based on five projects per year).

- A single module transportation analysis, previously costing over KRW 100 million, is now done in-house using STAAD automation tools.

- Cut module transportation analysis time by 75%, reducing two months of work to less than two weeks.

- Precast concrete design review time dropped from 1.5 months to about one week—an 83% reduction.

- Enabled review of more efficient structural systems, reducing material quantities by over 5%, saving approximately KRW 1.5 billion per project.

“The OpenSTAAD API and Command Editor provided by Bentley's STAAD can be an efficient tool for building design automation systems, and we have built design automation systems such as Piperack, Shelter, Equipment Structure, Shelter, Module, and Precast Concrete.”

– Dongwon Kim, Automated Design Project Manager, Hyundai Engineering

Solution

Hyundai Engineering used Bentley’s STAAD software to build two advanced automated design systems, overcoming the limitations of traditional outsourced structural analysis. At the core of their solution were the OpenSTAAD API and Command Editor. The OpenSTAAD API enabled Hyundai’s engineers to programmatically control STAAD’s structural analysis functions, allowing them to automate tasks such as model creation, load application, and results extraction. The Command Editor provided additional flexibility to automate detailed design parameters, load combinations, and complex shape modeling.

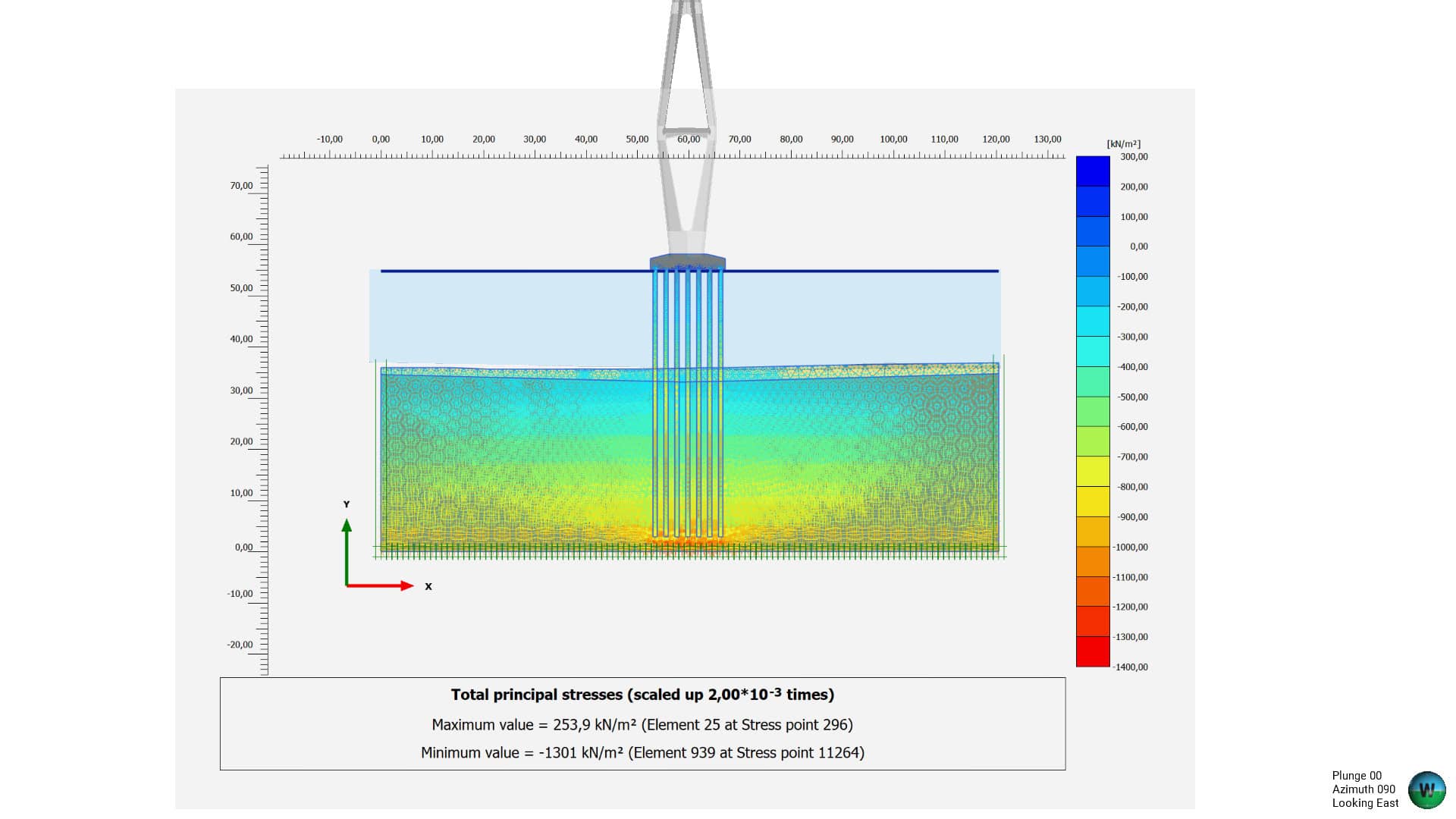

For module transportation, the new system automatically extracts key data, like the center of gravity, from existing models and applies all the forces that modules face during land and sea transport. For precast concrete design, the system automated the modeling of various shapes and connection points, placing each component based on the structure’s size. This automation speeds up the design process, improves accuracy, and reduces manual effort.

Outcome

By going digital with STAAD, Hyundai Engineering transformed its design process, eliminating costly outsourcing and improving efficiency. The company achieved significant cost savings of over KRW 750 million annually and drastically reduced design and review times by up to 80%. This newfound speed allows Hyundai to quickly evaluate project feasibility during bidding, boosting competitiveness and increasing the likelihood of winning new projects. The automation also frees up engineers to focus on more innovative and efficient design solutions.

Software

- STAAD.PRO: A comprehensive structural analysis and design software for buildings, towers, bridges, and other structures using a wide range of materials and international codes.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.