Hatch / Keeyask Hydroelectric Generating Station Project

nelson river, canada

Project

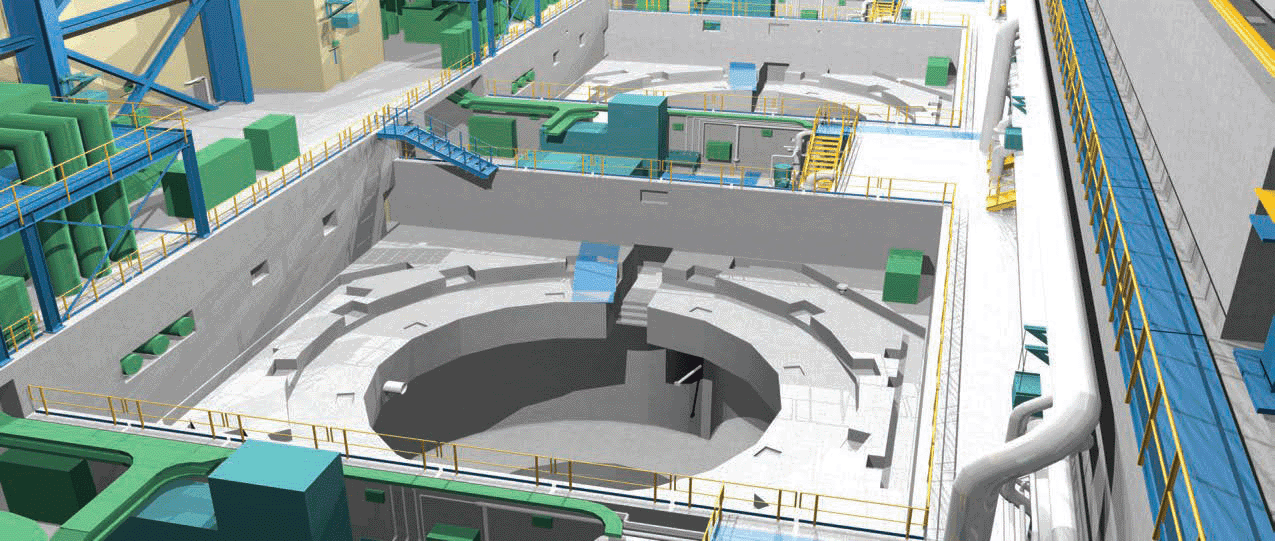

Manitoba Hydro retained Hatch Ltd. to design the 695-megawatt Keeyask Hydroelectric Generating Station as a source of renewable energy to increase electrical supply within the Canadian province, and serve export sales contracts. As this megaproject progressed into detail engineering, the Hatch team realized the critical need to develop 3D data-centric models, specifications, and construction drawings for the station’s complex concrete structures and surrounding infrastructure. To automate the checking required to reduce clashes between formwork, rebar, and embedded elements, and streamline the extensive field engineering, Hatch needed to utilize integrated, collaborative BIM methodologies.

Facts

- Hatch used Bentley’s BIM processes to design Manitoba Hydro’s 695-megawatt Keeyask Generating Station, which will provide renewable hydroelectric energy to approximately 400,000 homes annually and income to the Canadian province through export sales.

- ProConcrete allowed Hatch to develop a process to place rebar along the complex shapes of the hydroelectric concrete structure and generate standard rebar schedules and drawings, minimizing manual design and checking times.

Bentley’s 3D modeling tools ensured accurate design of concrete reinforcing and automated clash detection throughout the project lifecycle, accelerating resolution of fabrication and construction issues.

Using Bentley’s collaborative, interoperable modeling software and mobile applications as part of the early contractor involvement (ECI) process optimized information sharing. This enabled timely and accurate design changes to enhance construction planning and reduce overall project costs.

“By enabling Bentley 3D modeling, all participants benefited from increased information quality.”

– Kevin Rikley, Project Delivery Technlogies, Hatch Ltd.

Solution

Hatch used ProConcrete together with other Bentley products to create a coordinated 3D model across all disciplines, which improved design coordination and visualization from early contractor involvement (ECI) through to the design stage. Hatch produced accurate 3D rebar models for the concrete structures and automated clash detections to identify conflicts prior to fabrication and construction. To accelerate information sharing between the office and remote project site, Hatch used ProjectWise and iPads loaded with Bentley mobile applications.

Outcome

Using Bentley’s integrated BIM processes ensured accurate 3D modeling, automated and accelerated project deliverables, and optimized collaboration and information mobility, reducing project costs and delivery time, and enabling quicker resolution of fabrication and construction issues. Bentley’s modeling software helped determine discrete concrete pours, rebar placement, and the precise location of earthworks, to dramatically increase the accuracy of the project model. This minimized risks associated with quantity estimating and enhanced decision making in the field.

Software

ProConcrete

ProConcrete helped address the complex shapes within the model to enhance rebar design and was used during ECI to reduce turn-around-time for approval of detailed drawings. Bentley’s collaborative and interoperable 3D modeling tools—including OpenBuilding Designer, Bentley Raceway and Cable Management, gINT, OpenRoads, MicroStation, and Bentley mobile applications, improved design coordination and visualization among all project stakeholders, automated generation of deliverables, and produced accurate models and bills of material, reducing manual coordination efforts.