PowerChina Huadong Engineering Corporation / Jinsha River Longkaikou Hydropower Station Project

yunnan province, china

Project

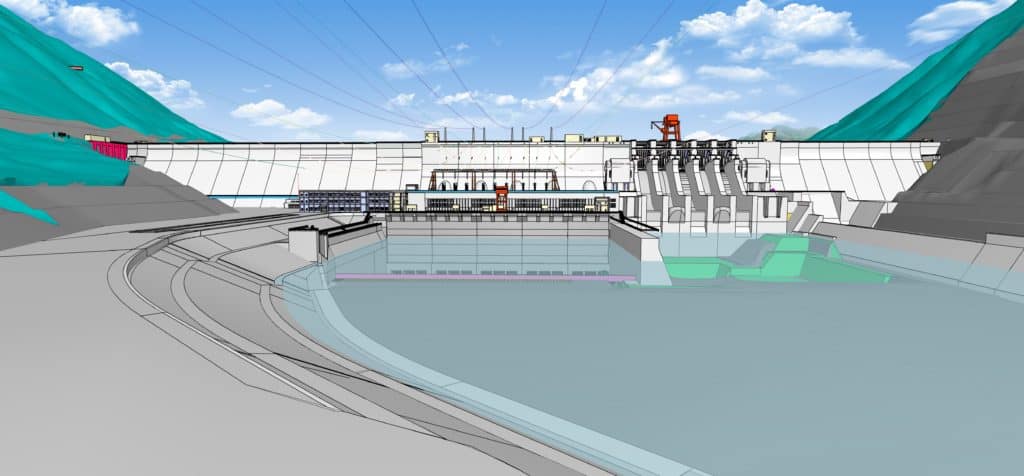

Longkaikou Hydropower Station, located in Yunnan Province China, is the sixth power station located within the Jinsha River. The station is a concrete gravity dam with five generator units and a maximum installed capacity of 1,800 megawatts. PowerChina Huadong Engineering Corporation was retained by Longkaikou Hydropower Co. Ltd. of China Huaneng group to develop the preliminary design, detailed design, construction, and handover of the CNY 8.9 billion project, which also included consideration of water supply, flood control, and irrigation.

Facts

- The Longkaikou Hydropower Station is the first hydropower station in China to employ BIM technology across the entire lifecycle of the project, from project survey through design, construction, and operations.

- The 3D digital design solution shortened design cycle, supported collaboration between construction and design, and improved overall service quality, enabling the project to be completed 10 months ahead of schedule.

- PowerChina Huadong Engineering Corporation’s customization of the Bentley software platform to deliver hydropower plants now sets the Chinese standards for such projects.

Solution

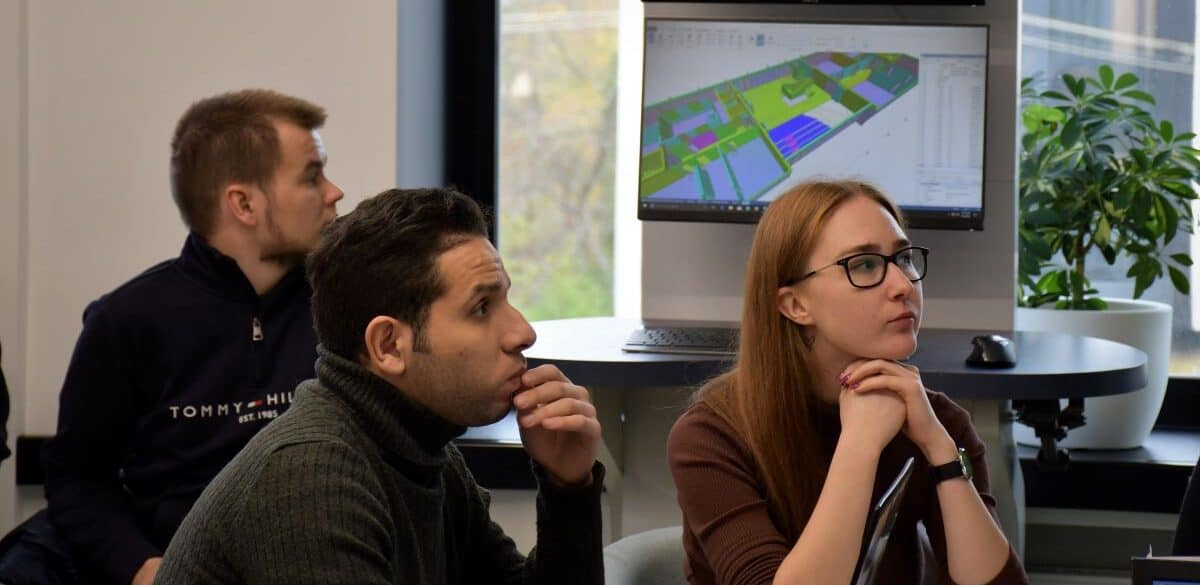

A building information modeling (BIM) solution of the entire project was created using Bentley technology. The 3D design solution included geological modeling and analysis, civil engineering, and plant engineering. Longkaikou Hydropower Station is the first hydropower project in China to comprehensively utilize 3D digital design technology in all principal design areas — geology, hub, and plant — all facilitated through tailored Bentley technology. The optimized platform improved product quality and significantly reduced 3D design collision problems and inaccuracies.

Outcome

Utilizing a Bentley BIM solution saved the company USD 300 million and enabled the project to be completed 10 months ahead of schedule through program optimization, saving up to CNY 1.79 billion. A complex topography and dam foundation with deep groves, rare in hydropower engineering, called for the comparison of design and construction scenarios with 3D modeling. The physical geology conditions were simulated through Bentley Map and Descartes, and optioneering methods were used to determine the optimal location and routing of the dam. Designs of the dam foundation’s excavation surface and deep grooves were conducted through MicroStation and GEOPAK. 3D digital design of the dam’s foundation surface saved CNY 194 million in engineering costs.

Software

OpenBuildings Designer

OpenBuilding Designer satisfied multiple system designs, including water retaining dam, flood discharge and energy dissipation, plant water inlet, dam crest layout, and more. A cooperative collaborative work platform was based in ProjectWise, streamlining communication and coordination among project disciplines and 3D modeling improved design efficiency by 40 percent. Bentley Navigator was used by the construction team to improve efficiency and minimize rework. Equipment collision rates were lowered by 95 percent and on-site design changes dropped by 80 percent with Bentley software.