CNI Ingenieros Consultores SAS

Bogota, Cundinamarca, Colombia

Building Heavy Materials in a Busy Pedestrian-trafficked Area

Pontifical Xavierian University’s master development plan includes a new, 14,089-square-meter, 15-story engineering laboratory and research building with three basement levels. CNI Ingenieros Consultores was tasked with designing the glass-and-steel structure. However, they faced several challenges, including being mindful of the project’s impact on neighboring buildings, the complexity of the anchoring systems and excavations of up to 16 meters to reach the foundation, and pouring 700 cubic meters of concrete for a laboratory’s reaction slab and walls. They also had to safely transfer materials and heavy-metal structural elements by crane, following strict industrial safety procedures to avoid endangering students and faculty walking on campus.

Managing Careful Coordination among Project Team Members

CNI Ingenieros realized that they had to plan carefully to coordinate the architecture and project installation. After considering their options, they decided that robust analysis software would help them quickly resolve issues, while enabling them to examine other scenarios. They also needed to improve the flow of information between them and the architect. Additionally, since the basement floors were made of concrete and the tower structure was metal with a structural façade composed of tubular profiles, they searched for a solution that would allow them to address the entire structure.

Structural Steel Analysis Leads to High Level of Detail

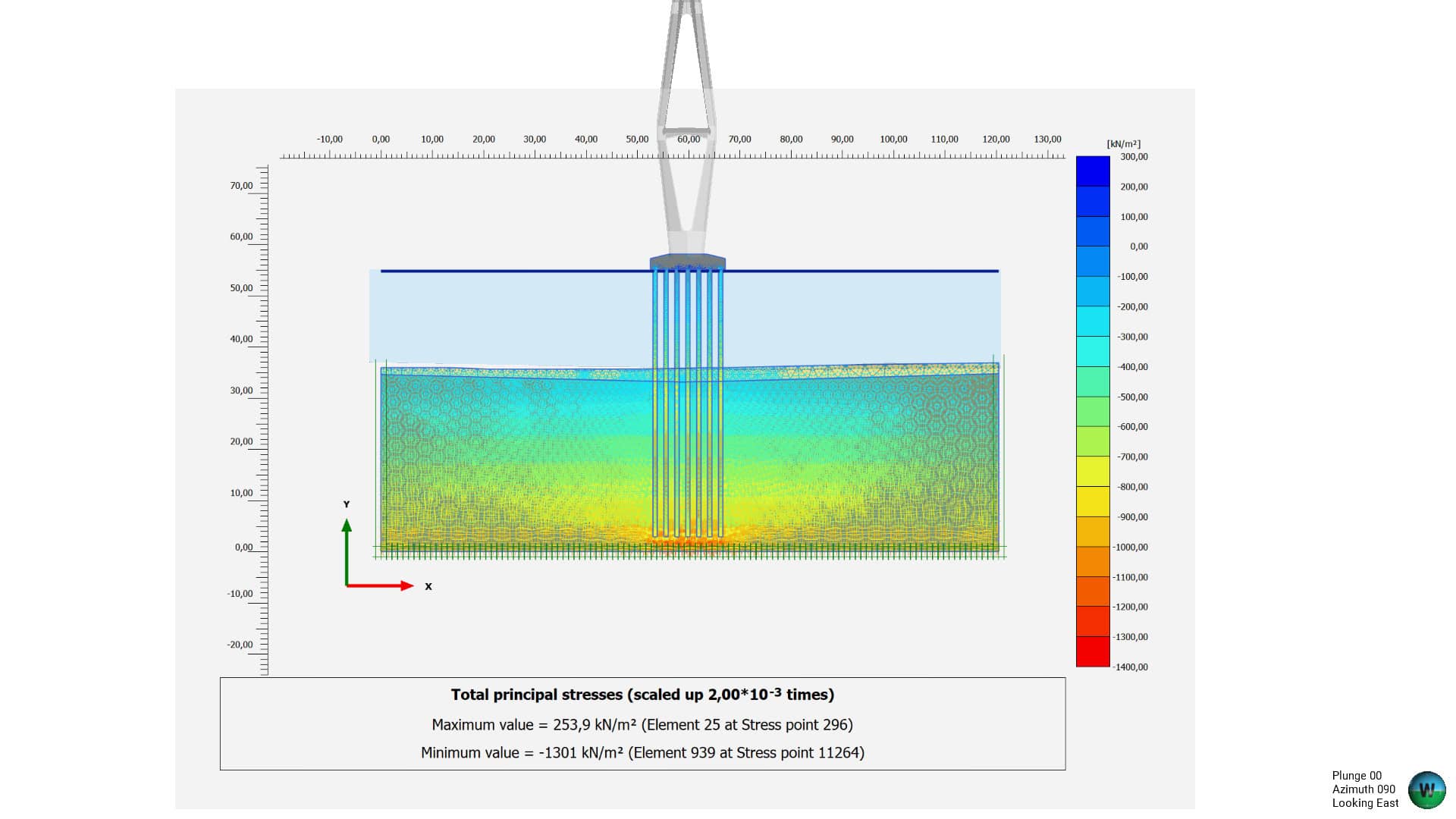

After considering all their options, CNI Ingenieros chose to use RAM Structural System software to optimize the geometric designs of the visible structural connections, as well as perform material and structural analysis in STAAD.Pro structural analysis and design software. Moreover, they ensured pedestrian safety by running all crane lifting processes through the application. The ability to optimize the steel sections, as well as to efficiently design their connections to achieve their integration in the architectural design, made it possible to produce a stunning appearance with a high level of detail. The design allowed the university to select appropriate contractors and builders to meet their high level of detail and specifications, which resulted in producing more accurate contract specifications and budgets, enabling them to control cost overruns. Additionally, they used PLAXIS geotechnical analysis software and STAAD.Pro to help them excavate the basement floors and pour the concrete by analyzing alternatives to mitigate delays. STAAD.Pro’s structural analysis capabilities helped them determine how to lift and align sections of the metal tower, some of which weighed 7 tons.

Analysis of Assembly Stages Saves Time to Meet Schedule

CNI Ingenieros sped up engineering analysis and data processing obtained in the field, which improved decision-making, reduced resource hours, and saved costs. The capacity for performing structural analysis of the partial assembly stages made it possible to provide technical support for the assembly phases, evaluate deformations and tolerances, and establish a rapid response to definitions on site. Additionally, the structural and geotechnical analysis software enabled them to propose new construction sequences for excavation and land containment, which reduced excavation time by eight weeks.

Facts

- A new, 15-story engineering research building is part of Pontifical Xavierian University’s master development plan.

- Optimizing steel sections made it possible for CNI Ingenieros to obtain a stunning appearance with a high level of detail.

- Structural and geotechnical analysis software unveiled alternative construction sequences that enabled CNI Ingenieros to reduce excavation time by eight weeks.

“Bentley’s structural analysis tools made it possible to efficiently resolve the complex structural design of the building and its detail to achieve a structure that is visible and integrated with the architecture, and to support construction and assembly decisions thanks to easy modeling and reliable results.”

– Nicolas Parra Garcia

General Manager, CNI Ingenieros Consultores SAS