In the pursuit of a more sustainable world, companies are innovating ways to reduce environmental impact while delivering essential services. Nippoh Engineering Co., Ltd., located in Yokohama, Japan, is at the forefront of this movement with a visionary project aimed at achieving affordable and clean energy with a steam turbine piping design. Aligned with Japan’s goal of carbon neutrality by 2050, they are delivering a new thermal power plant designed to eliminate greenhouse gas emissions and contribute to the revitalization of their region.

In this blog, you will learn what Nippoh achieved utilizing Bentley software, including:

- 50% reduction in resource hours

- 10% material cost savings

- 20% productivity improvement

- 2,000-3,000 new jobs created

For over 50 years, Nippoh Engineering Co., Ltd. has been designing plants that power communities in Japan and around the world. Today, they are taking that expertise further by creating cleaner, greener energy solutions. As part of their commitment to the UN’s Sustainable Development Goals—especially Goal 7: Affordable and Clean Energy—they’re developing next-generation plants that use innovative technologies such as ammonia and biomass co-firing, as well as methanation, to reduce environmental impact and build a more sustainable future.

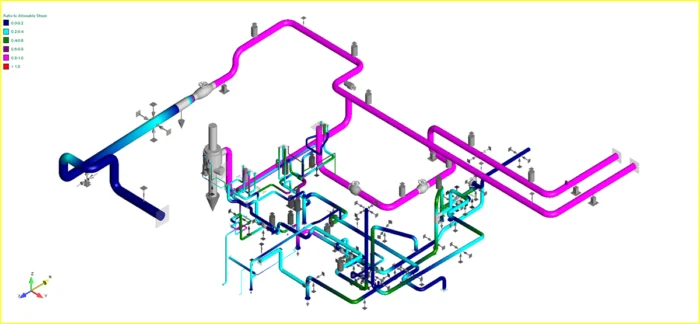

Their basic design concept is ambitious: ensuring allowable stress ratios and loads while specifically aiming to minimize the use of spring hangers to design the piping without support gaps. These technical requirements presented significant design difficulties, compounded by data integration and change management challenges. Overcoming these hurdles necessitated flexible and robust pipe stress analysis and design technology.

To tackle these complex challenges, Nippoh turned to advanced digital software, specifically AutoPIPE and STAAD. They imported CAD data directly from the 3D model into AutoPIPE to create a detailed piping model. A key part of their process involved using AutoPIPE to perform stress analysis on the innovative design that sought to eliminate spring hangers, ensuring that loads were effectively absorbed.

Working in a 3D piping software environment enabled Nippoh to quickly evaluate various design alternatives. This digital workflow allowed them to easily transfer analysis results, leading to a remarkable reduction in resource hours by approximately 50%.

By successfully developing a design using fewer spring hangers, Nippoh achieved a 10% reduction in material costs compared to conventional designs. Furthermore, their embrace of a digital workflow and advanced analysis software led to a significant 20% improvement in overall productivity.

Nippoh Engineering’s project demonstrates how leveraging sophisticated design and analysis technology can help overcome complex technical challenges in pursuit of critical sustainability goals. The construction of this new plant in a quiet rural area is more than just an energy project—it’s a catalyst for regional revitalization. Drawing on past examples where thermal and nuclear plants have boosted local economies, this initiative is expected to create between 2,000 and 3,000 new jobs. Beyond economic impact, it holds the promise of keeping young talent rooted in their communities, helping to reverse the trend of rural depopulation and breathe new life into the region.

Learn more about Bentley’s AutoPIPE, Bentley’s pipe stress and vessel analysis software.