When I started working in water distribution system modeling, building a model, and getting it to run was so difficult and time-consuming that getting any results was a major accomplishment. There wasn’t much time left in the project to do a great deal of checking whether the model results were close to field observations.

The first paper that discussed model accuracy was written by Eggener and Polkowski (1983) from the University of Wisconsin in a study of the town of Menomonie, Wisconsin. They compared a few field pressures with model results and declared they had an accurate model. This was a big step forward, but they only looked at model behavior under normal conditions and they did not answer the key question: “Why would there be discrepancies between a model and field data?”

While models can be used to simulate average conditions, the real value for the design comes from planning how to deal with conditions when the distribution system is stressed, such as peak days, component failures, fire flows, or future demands. If a model only works when the hydraulic grade is flat, it isn’t useful for high flow conditions. In a study I conducted on Guam in the early 80s, I was the first person I knew of who used fire hydrant flow tests to produce a range of conditions with which to stress the model to ensure calibration over a wide range of flows.

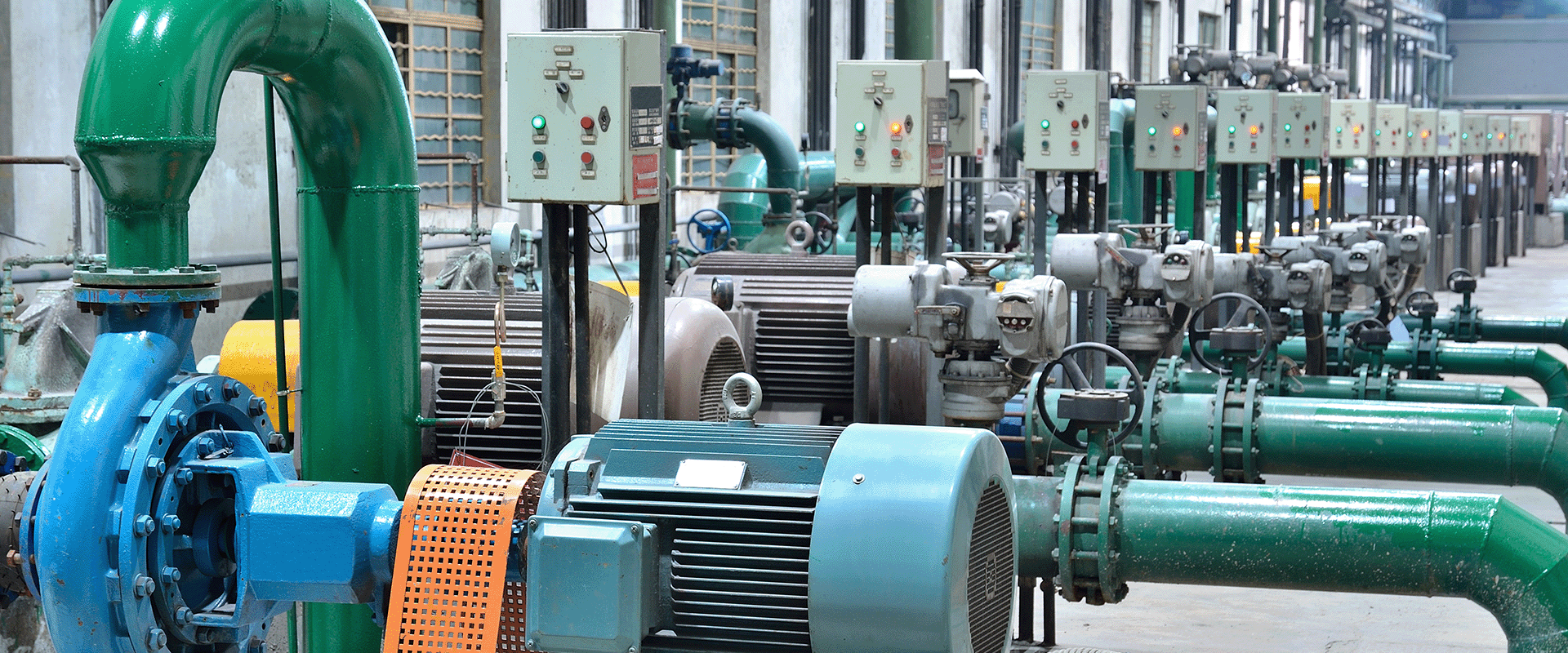

These days, hydraulic models of water distribution systems have become an essential tool for the planning, design, and operation of water systems. It’s hard to think of a case nowadays where engineers and operators would size an important pipe, select a pump, evaluate fire flows, or any number of other tasks without checking with their hydraulic model.

Models have become a trusted tool across the industry. The extent to which they can be trusted depends on how closely the model results correspond to actual system behavior. If the pressure at a point in the system for a given set of conditions is 65 psi, the model should calculate pressures very close to 65 psi.

How can that be assured? The key is model calibration where comparisons between real-world and model results are checked. If they agree, confidence in the model increases. If there are discrepancies between the model and field data, it’s time to improve the calibration of the model or identify problems with the data.

If there was only a single reason that such discrepancies exist, calibration would be easy. However, there are dozens of reasons for these types of discrepancies, including incorrect pipe roughness, inaccurate pressure gauges or flow meters, water leaking in and out of adjacent pressure zones, isolation valves in the system that were not in their correct position, air blockage at high points, pump curves that have changed, and many other reasons. Modelers can become overwhelmed with possible adjustments to arrive at a calibrated model.

Model calibration can look like a daunting task because it is hard to determine WHY the models and field data disagree. Finding the problems and correcting them sounds easy in theory but experienced engineers can tell you that there are a lot of pitfalls and plenty of tricks for avoiding them along the way.

The process can be different depending on whether the model is being used for system planning, tank sizing, pump selection, real-time operations, water quality issues, or energy management. But the basic goal is still the same―creating a model that behaves like the real world. However, there is finally a book that clarifies this process to get to the goal of calibration―a model that can be applied with confidence to help support decision-makers.

About 12 years ago, the Calibration Subcommittee of the Engineering Modeling Applications Committee decided to write a book about calibration, Handbook of Water Distribution System Model Calibration. After a few years of procrastination, we completed the first draft of the outline in 2013. Now, after 10 years of work, we are an overnight sensation. The book lays out a logical path through complicated data and hydraulics to find any problems and correct them.

I was supposed to write a chapter, but by the time the dust settled, I had written or co-written three and a half of the seven chapters. I’ve invested a lot in this book, and I’m delighted to see it published. I also wanted to reach my secondary goal for this project―completing the book before I died. It looks as if I made it.

While it may not be obvious from the cover … remember, “You can’t judge by its cover.” This is an excellent book about model calibration that will serve as an important reference for a long time.

The handbook is now available from AWWA as a PDF ($69 for AWWA members). I haven’t seen a paper copy ($99 for AWWA members) yet, but the digital version has been available since November 2023. The Handbook of Water Distribution System Model Calibration can be purchased from the AWWA website at

https://engage.awwa.org/PersonifyEbusiness/Bookstore/Product-Details/productId/92298835

Get the book and dazzle your coworkers with your knowledge of model calibration. (Disclosure: I do not make any money from the sales of this book.)

Reference

Eggener, C.L. and Polkowski, L., 1983, “Network Models and the Impact of Modeling Assumptions,” Journal AWWA, Vol. 68, No. 4, p. 189.

If you want to contact me (Tom), you can email [email protected].