Are you concerned about the integrity of the joints of your fixed or floating facilities? We can handle a simple tubular joint by using established empirical relationships prescribed in the codes. A pure non-tubular or tubular to non-tubular or a stiffened complex joint either requires a rigorous closed formed solution or additional FEM analysis using industry-standard Finite Element software. Well, it is no longer a necessity with SACS Joint Mesher capability at hand!

This online comprehensive training takes you through the step-by-step methodology of using SACS Joint Mesher capabilities. Learn how to model any type of joint geometry in the FEM domain within the normal facility design space. We further use these capabilities to model lifting appliances, e.g., padeyes, trunions, and any other complex connections like skirt piles or crane/equipment. The joint mesher capability may also be used to extract stress concentration factors [SCF] of any non-conventional and stiffened joints generally required for further fatigue check.

There are few ways of creating joint meshes either from the SACS Executive Screen or from SACS Preceed or Modeler by selecting a joint or using a pre-generated joint mesh input file. In either way, the user needs a basic SACS input model to start with. The following video explains how to make a head start on this important feature in SACS.

Simple Joint Mesher Using SACS Preceed

Joint Mesher - Other Options

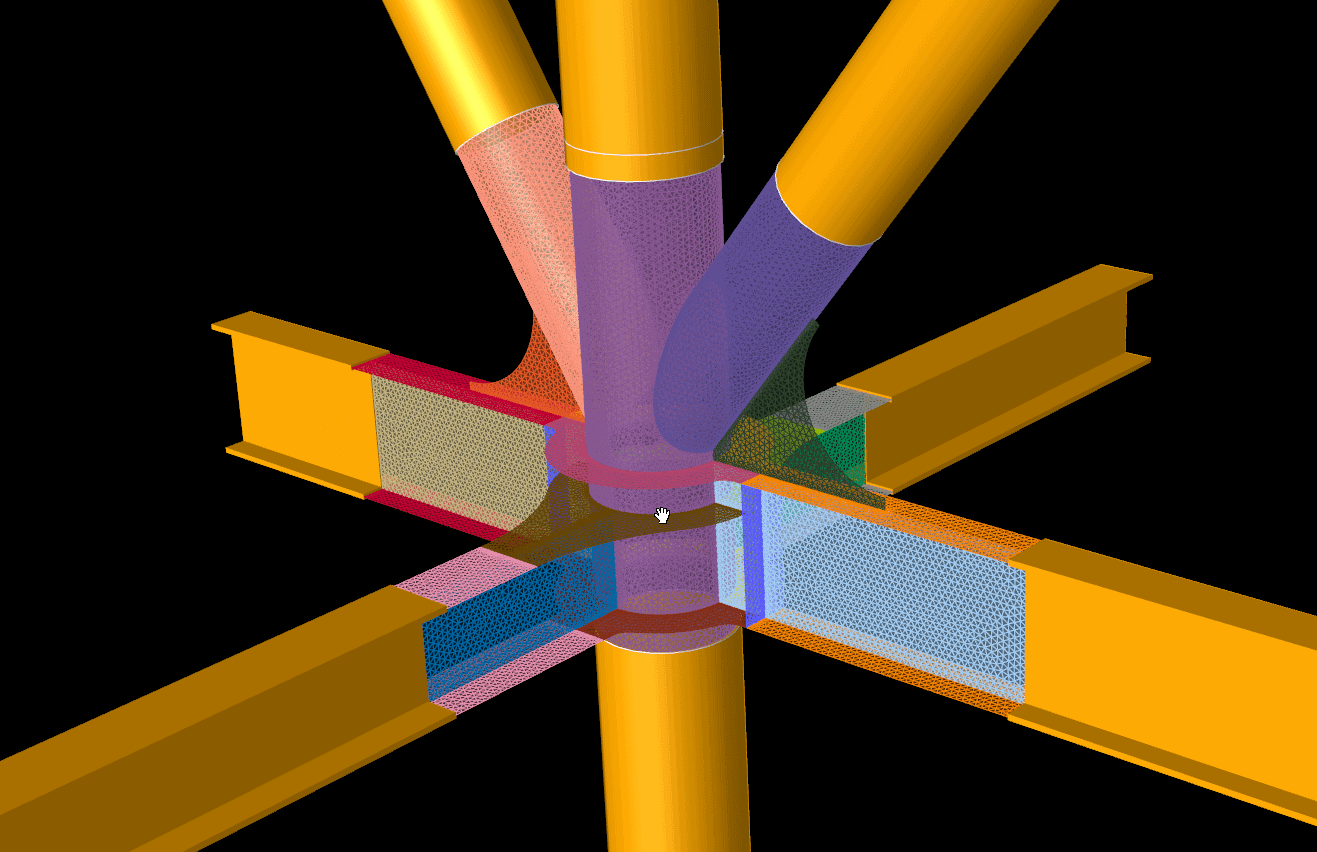

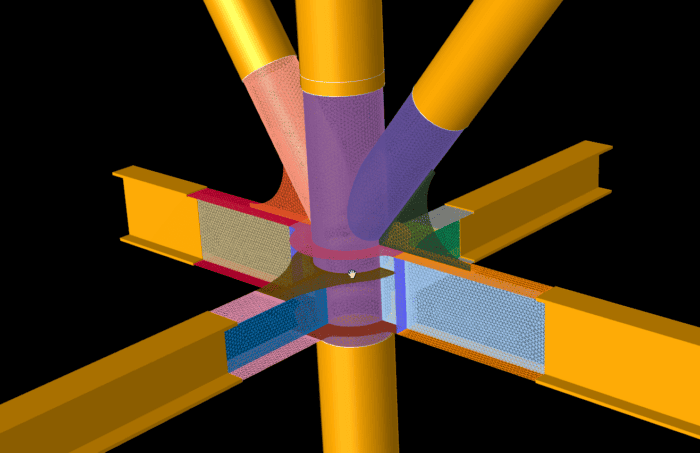

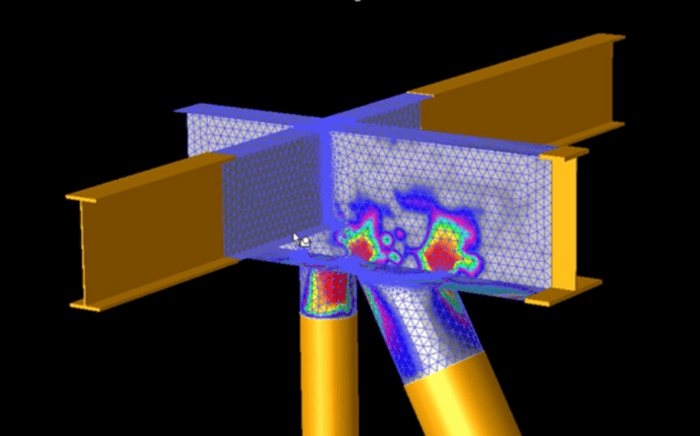

Additionally, in the second part, we may design a stiffened tubular or non-tubular joint by using SACS Joint Mesher comprehensive Graphics User Interface [GUI] and develop the complex geometry of the joint. The final analysis will be similar to standard static and other analyses in SACS. The plate stresses generated thus will ensure the adequacy of the joint design. Some complex joint models developed in SACS Joint Mesher and subsequent stress analysis results are shown in the following figures.

Join Mesh of the Stiffner Plates

Join Mesh of the Stiffner Plates Stress Concentration Factor

Stress Concentration FactorLooks Interesting! We have a fully-developed comprehensive on-demand training on Joint Mesher capabilities in SACS. To learn more about the course, access here. You can also check out other On-Demand Training Courses on Bentley’s eStore website.