Leaks in water distribution systems depend on the pressure in the pipe. Given a certain size opening, the leakage is roughly a function of the square root of pressure. If you lower the pressure, you’ll get less leakage.

Downside to Pressure Control

But there is a downside to pressure control. (If pressure is zero, you can eliminate all leakage.) Customers like a reasonably high pressure and are quick to complain when they feel it is inadequate. The key is to find the right pressure. Pressure reduction can not only impact the flow from a leak but the number of leaks.

Pressure control is usually not applied to the entire system but rather to individual pressure zones or district meter areas. We’ll call them “zones” for this blog. Zones which are directly fed by elevated storage are usually poor candidate for pressure control because it is difficult to raise or lower tanks. However, zones can be isolated from the main zone by valving and that is where cost comes in.

Essentially Three Levels of Pressure Control

There are essentially three levels of pressure control:

- None

- Conventional pressure reducing valves (PRV)

- Real time pressure control (RTC)

Number one is self-explanatory. Number two is a conventional pressure reducing valve. These are simple, hydraulically controlled valves which require no power. They reduce the outlet pressure of the valve to a fixed setting. Except in very warm climates these are placed in buried vaults. Some may be placed in structures.

Number three is the most effective but also the most complex and expensive. It consists of:

- A sensor at the valve vault (Local RTC) or at some other key locations such as critical customers or high points (Remote RTC).

- Communication to a controller (usual a programmable logic controller (PLC))

- The PLC to control the valve

- A motorize valve actuator

- Power supply

With RTC, it is possible to adjust the valve based on pressure, demands, time or any combination. For example, pressures can be turned down at night when pressures tend to creep upward due to low demand.

Which of the three is best?

Simulation Using WaterGEMS

My colleague from the University of Pavia, Enrico Creaco (Creaco and Walski, 2017, 2018) and I have written a set of papers on this. (See references below, plus a few other papers.) We varied a set of parameters such as amount of leakage, value of water, size of system, shape of demand pattern and how high the pressures are. We simulated these options using WaterGEMS.

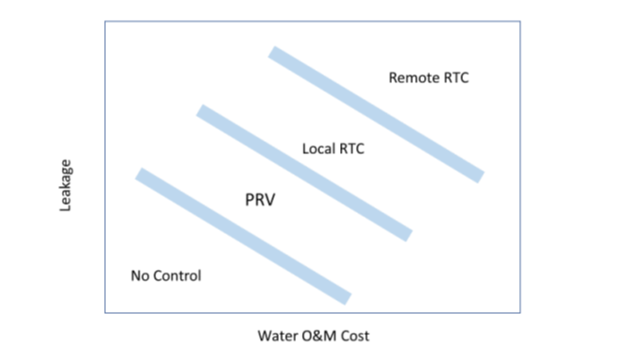

The conclusions were fairly consistent with common sense with two extreme cases and PRVs in the middle.

- No controls, when water is inexpensive, leakage rates are low, and demands don’t vary much.

- RTC, when water is very valuable, leakage rates are high, and demand vary widely.

Between those two extreme cases, PRVs are best and are the most common solution when pressure control is desired.

The results are shown graphically in the figure below. There is no scale on the axes because the cutoffs depend on local costs.

Cost of Water is not the Price of Water

The cost of water is not the price of water that customers pay. (Price is important for reducing apparent loss.) Instead, it is the savings from reducing leakage and is usually dependent on pumping energy and chemical cost. Such costs as amortization of capital investment, operations and maintenance, engineering and customer service staff and meter reading and replacement are not reduced by reducing leakage. The one exception to this would be a system that must incur a large capital investment (upgrade treatment plant, install new wells) if leakage isn’t reduced.

Of course, pressure control should be part of an overall program for reduction in non-revenue water which would include leak detection and repair, monitoring, theft reduction and meter maintenance.

To get more in depth information on this topic see:

- Creaco, E. and Walski, T., 2017. “Economic Analysis of Pressure Control for Leakage and Pipe Break Reduction,” Journal of Water Resources Planning and Management, Vol. 143, No. 12, December, DOI 10.1061/(ASCE)WR.1943-5452.0000846.

- Creaco, E. and Walski, T. 2018, “Operation and Cost-Effectiveness of Local and Remote RTC”. Journal of Water Resources Planning and Management, Vol. 144, No. 11, November. DOI: 0.1061/(ASCE)WR.1943-5452.0000993, (with Enrico Creaco).

- Creaco, E., Campisano, N. Fontana, G. Marini, P.R. Page and T. Walski, 2019. “Real Time Control of Water Distribution Networks: A State-of-the-Art Review,” Water Research, 161, 517-530, 2019 DOI.org/10.1016/j.watres.2019.06.025.

- Walski, T., Bezts, W., Posluszny, E., Weir, M. and Brian Whitman, B., 2005, “Modeling Leakage Reduction through Pressure Control,” Journal AWWA, 97, No. 4, p. 147, April.

- Walski, T., Brian Whitman, B., Baron, M., and Gerloff, F., 2009, “Pressure vs. Flow Relationship for Leaky Pipes,” EWRI Conference, Kansas City, May.

If you want to contact me (Tom), you can email tom.walski@bentley.com.

Want to learn more from our resident water and wastewater expert? Join the Dr. Tom Walski Newsletter today!