Valves tend to be the most ignored appurtenances in our systems … until you need them, then they are the most valuable. If you never had to shut down a portion of your distribution system to repair a break or do some other maintenance, you wouldn’t need any isolation valves. But in the real world, stuff happens and if you didn’t have any isolation valves, you would need to shut down the entire system to do any work. That’s why we have isolation valves (usually gate valves) throughout our distribution systems.

Segments

When you are planning to do a non-trivial shutdown, it is best to analyze the impacts of the shutdown with your hydraulic model (i.e., OpenFlows WaterGEMS/WaterCAD). Some engineers model the effect of a shutdown by closing a pipe element in the model. This is acceptable in the case where you have a valve at each end of the pipe element. However, in many cases, there is not a one-to-one relationship between the extent of the shutdown and a single pipe element. When you shutdown, you are closing a distribution system segment which is defined as the “smallest portion of the distribution system that can be isolated.” (Walski, 1993; Abdel-Mottaleb and Walski, 2021)

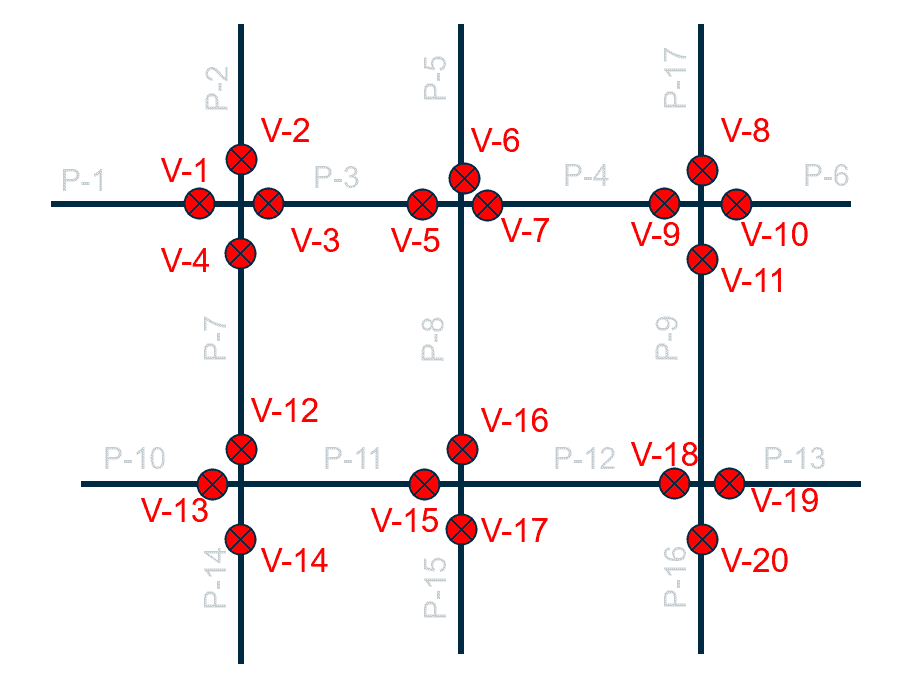

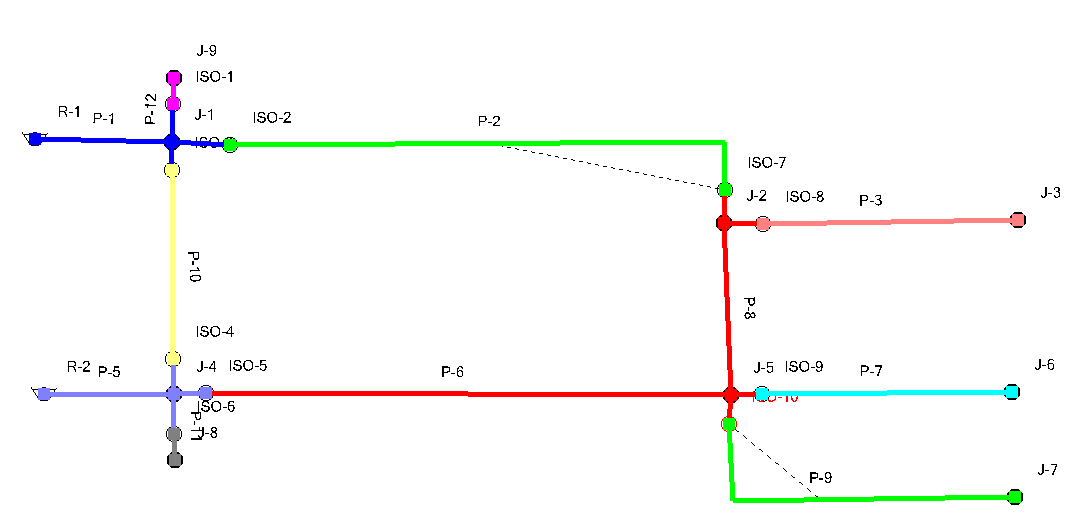

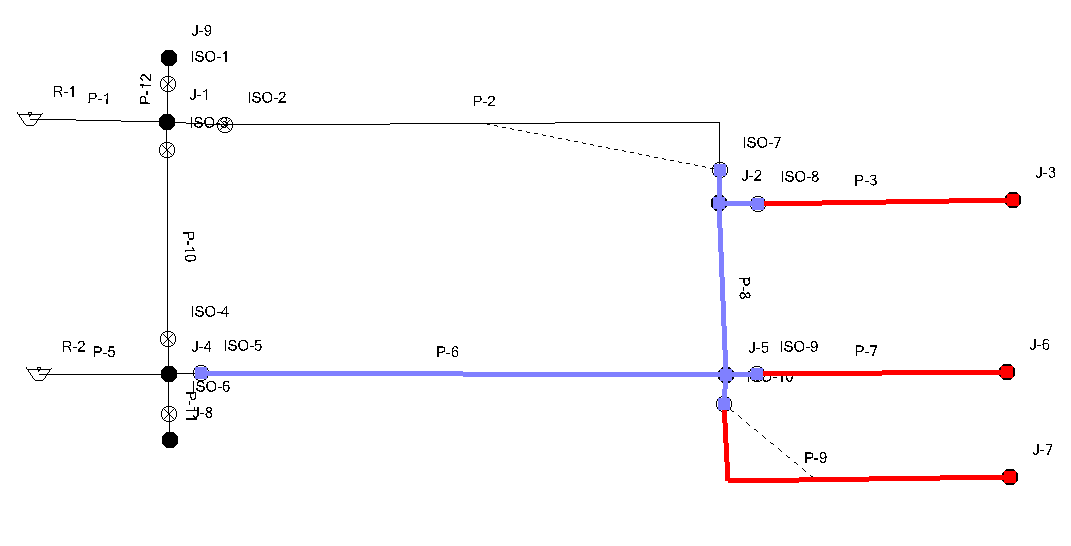

Let’s take a look at the given system below.

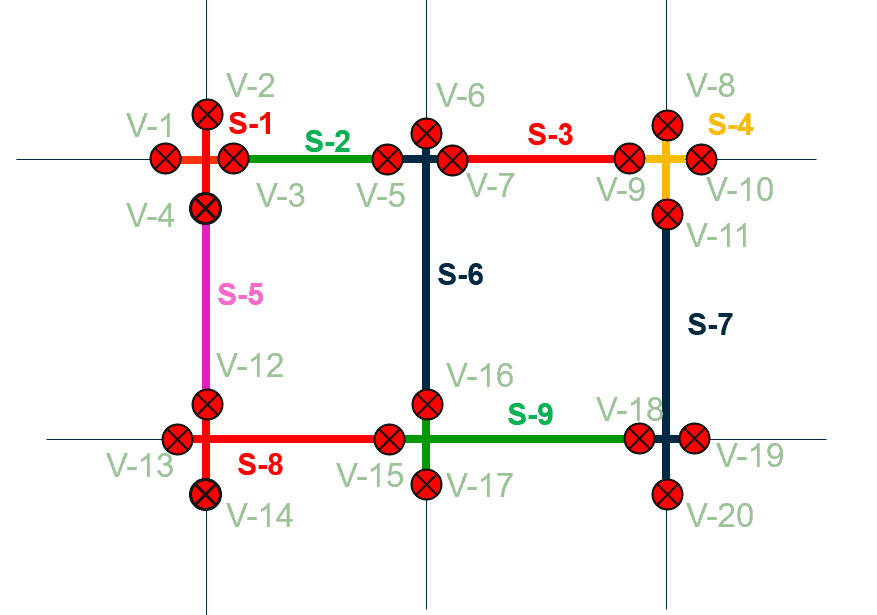

Each segment is shown in a different color below (S-1, S-2, S-3, etc.).

Notice that a segment can be a single pipe (S-5), a cluster of short pipes at an intersection (S-1), or several pipes and tee or cross fittings (S-6). Failing to account for the exact location of valves can lead to misleading results if you try to model the shutdown by removing a single pipe from the system.

There are two situations where identifying segments is important.

1. Systemwide design and rehab planning

2. Individual shutdown

What do you look for in segments? What you’d like to see are segments that are small (a few hundred feet), require very few valves in order to be isolated (preferably two), and will not cause disruption of service in downstream segments, especially for critical customers. These shortcomings can be corrected by installing additional valves to reduce the number of valves that must be operated to isolate a segment or by installing additional paths for water to get around an isolated segment.

Systemwide Analysis

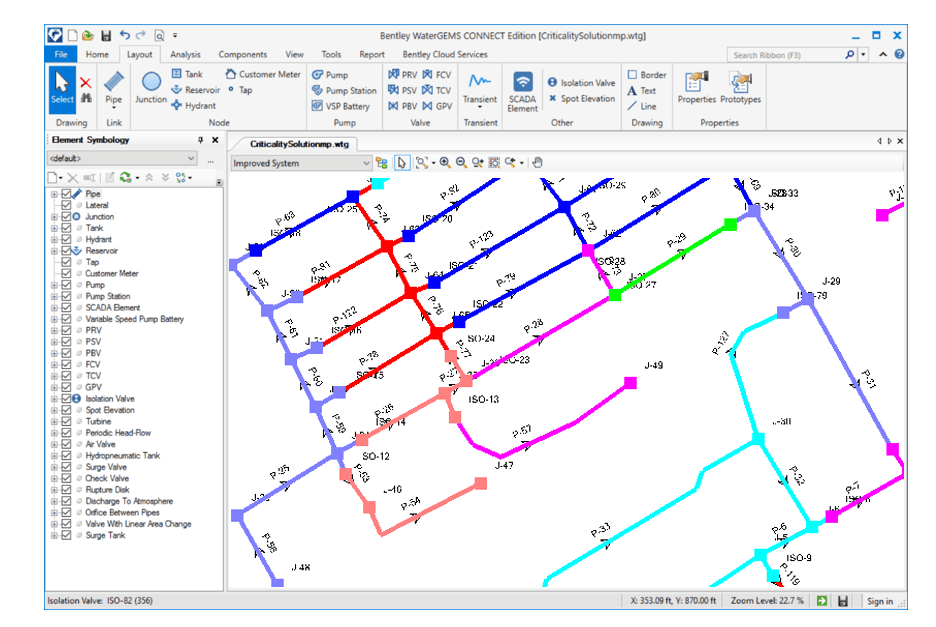

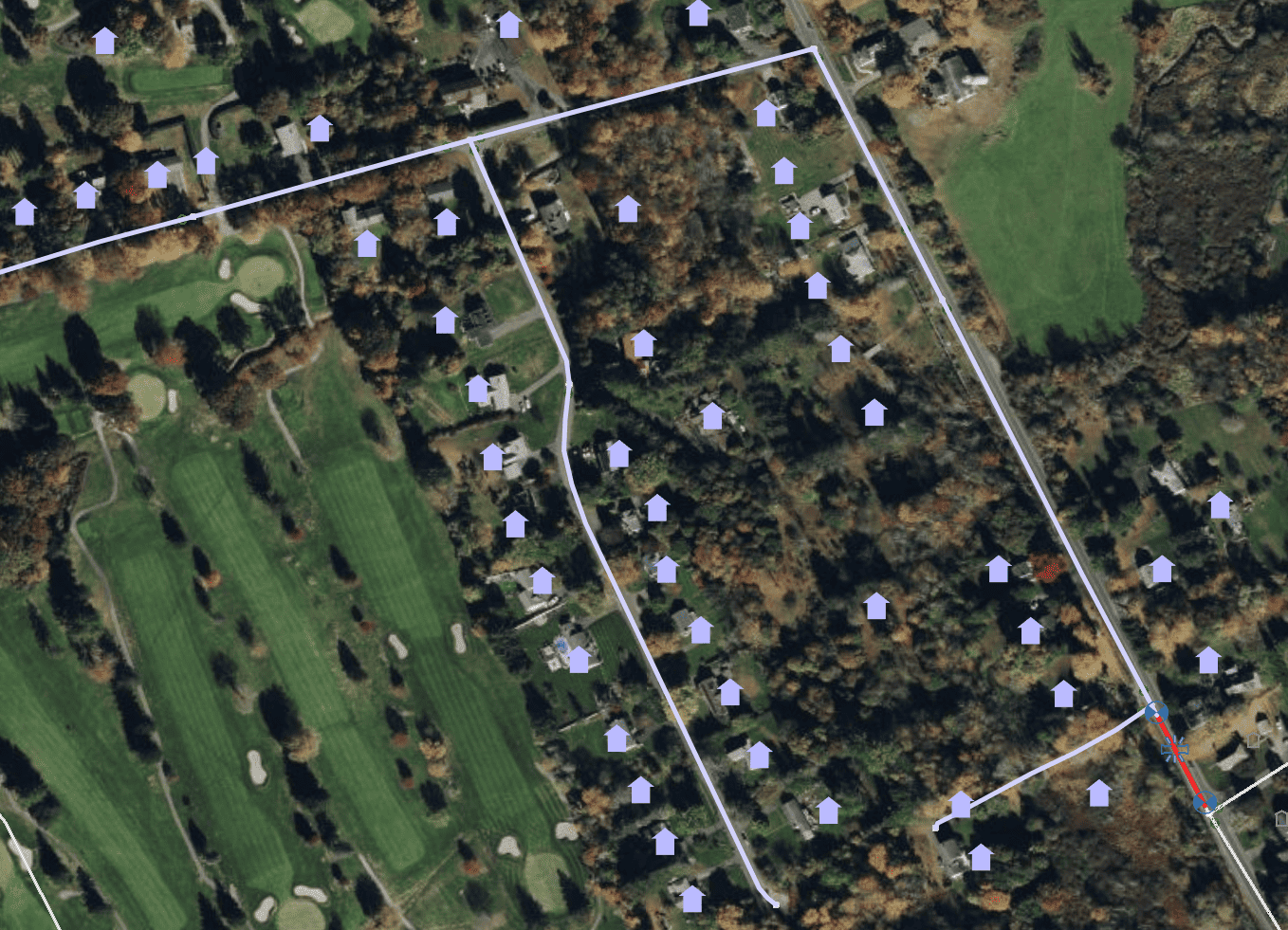

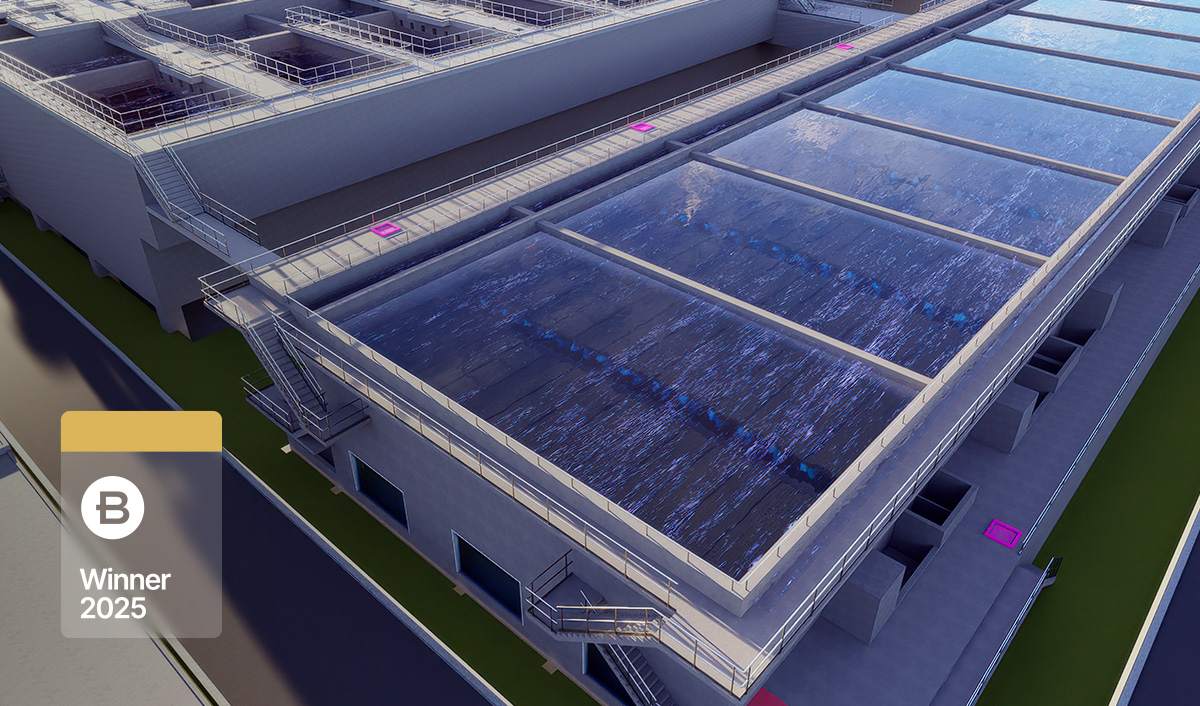

During system design or operational studies, it is desirable to identify all segments in the system or some subset of the system. In a single run, OpenFlows WaterGEMS/WaterCAD can display every segment and color each one making it easy to identify segments that are large or could have significant downstream impacts as shown below.

For each segment, the model will identify the length of the pipe and the number of valves to operate for isolation so that problematic segments can be identified. Most segments will be small and isolatable. However, there usually will be some that may require 8 valves for a shutdown or have 2000 ft of pipe. These can be addressed. If you have assigned customer meters to your model, segmentation can display the exact customers who will be out of water during a shutdown.

Identifying segments is the first step in WaterGEMS Criticality analysis. The next step would be to run WaterGEMS/Criticality which would show the segments that would most seriously impact users in terms of shortfall in meeting demands. While a segmentation run shows the segments and their properties based on their connectivity, a criticality analysis uses the hydraulic solver to show pressures and flows as well as connectivity.

Individual Shutdowns

While operators are interested in the general placement of valves, they tend to be even more interested in how they can respond to a request to shut down a specific break or other maintenance event that is happening now or in the near future. This can be done with WaterGEMS’s segmentation or with WaterSight’s Event Response to a pipe break.

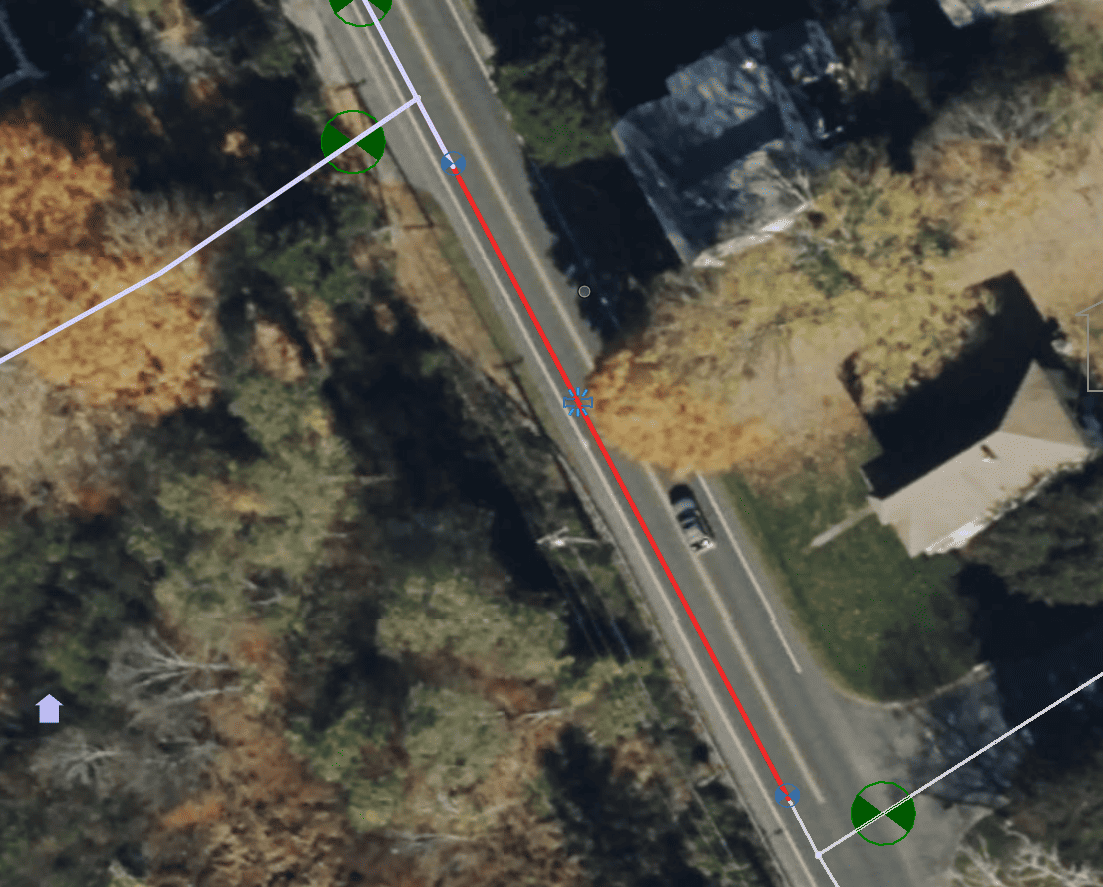

The segment to be isolated is the red segment below which has no customers attached to it and only two valves need to be closed to isolate it. It looks inconsequential.

However, if you were to zoom back, WaterSight would show you that there are 53 customers (orchid-colored houses) out of water because the segment was the root of a tree-shaped segment downstream.

In most cases, a routine shutdown requires 2 to 4 valves to be operated and only puts a handful of customers out of service during the shutdown. The more interesting cases are due to failure of one or more valves to be operable, inadequate valving to start with, large transmission mains with widely spaced valves, or valves serving a critical customer. These problematic shutdowns are illustrated in the following section.

Problematic Shutdowns

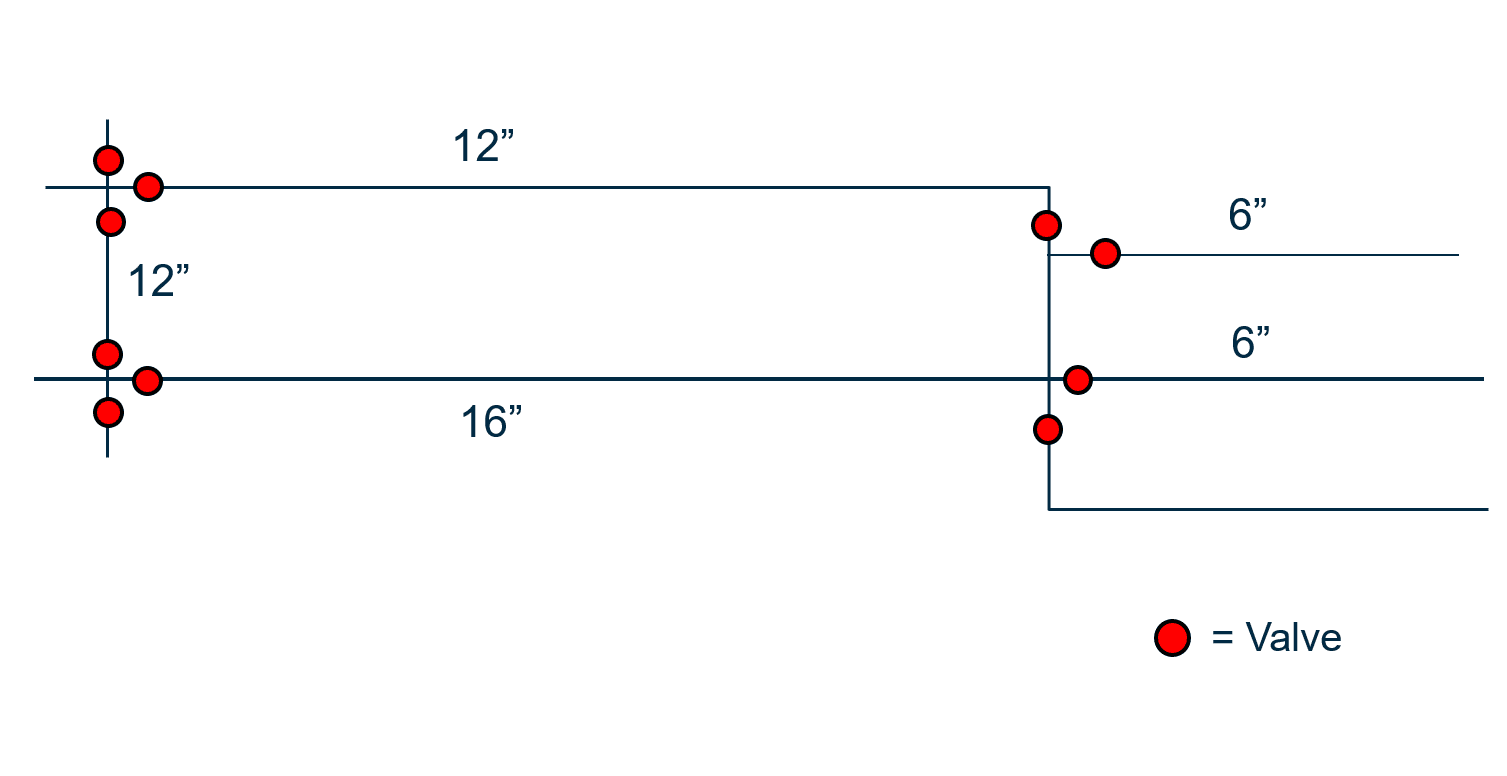

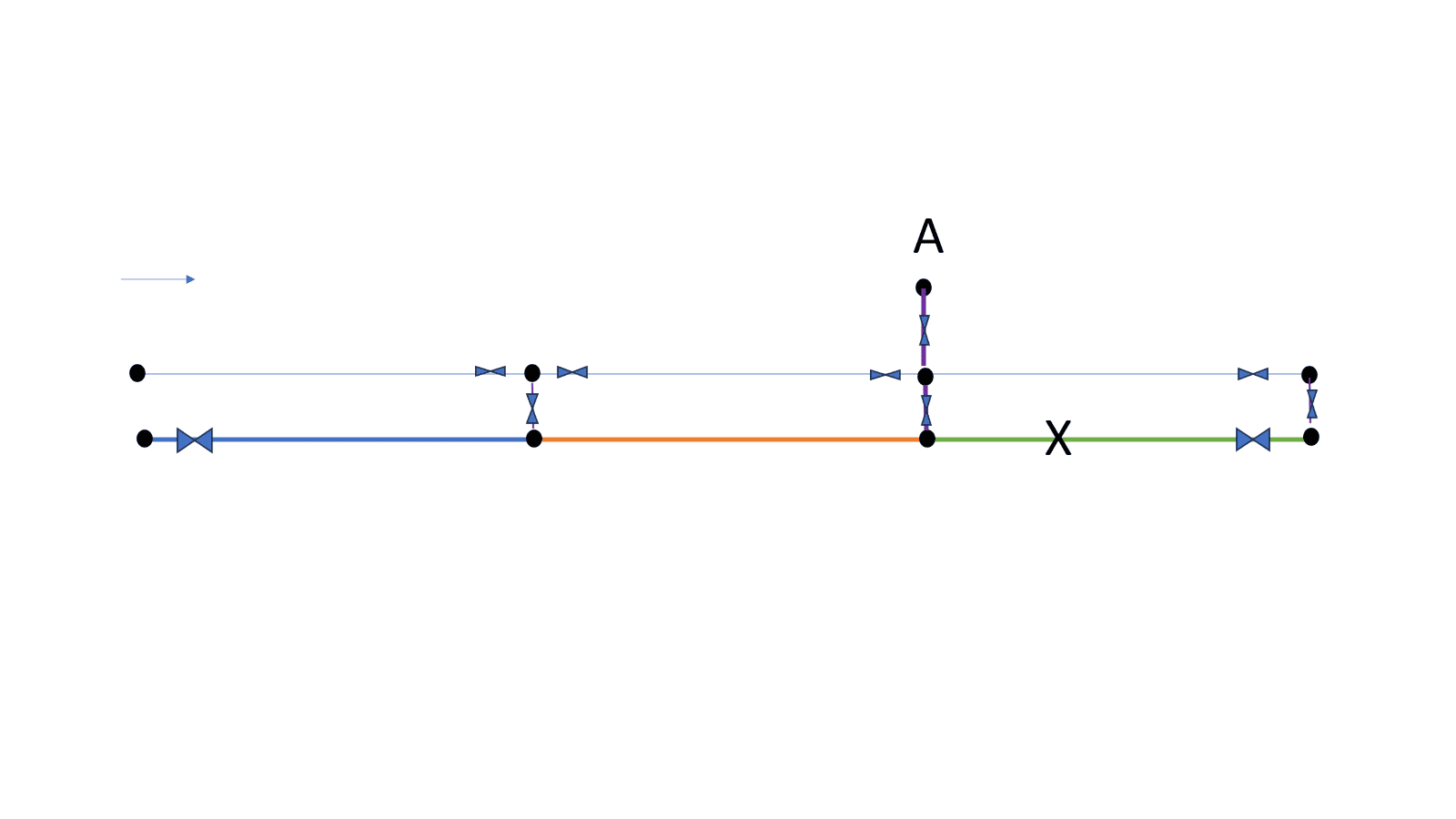

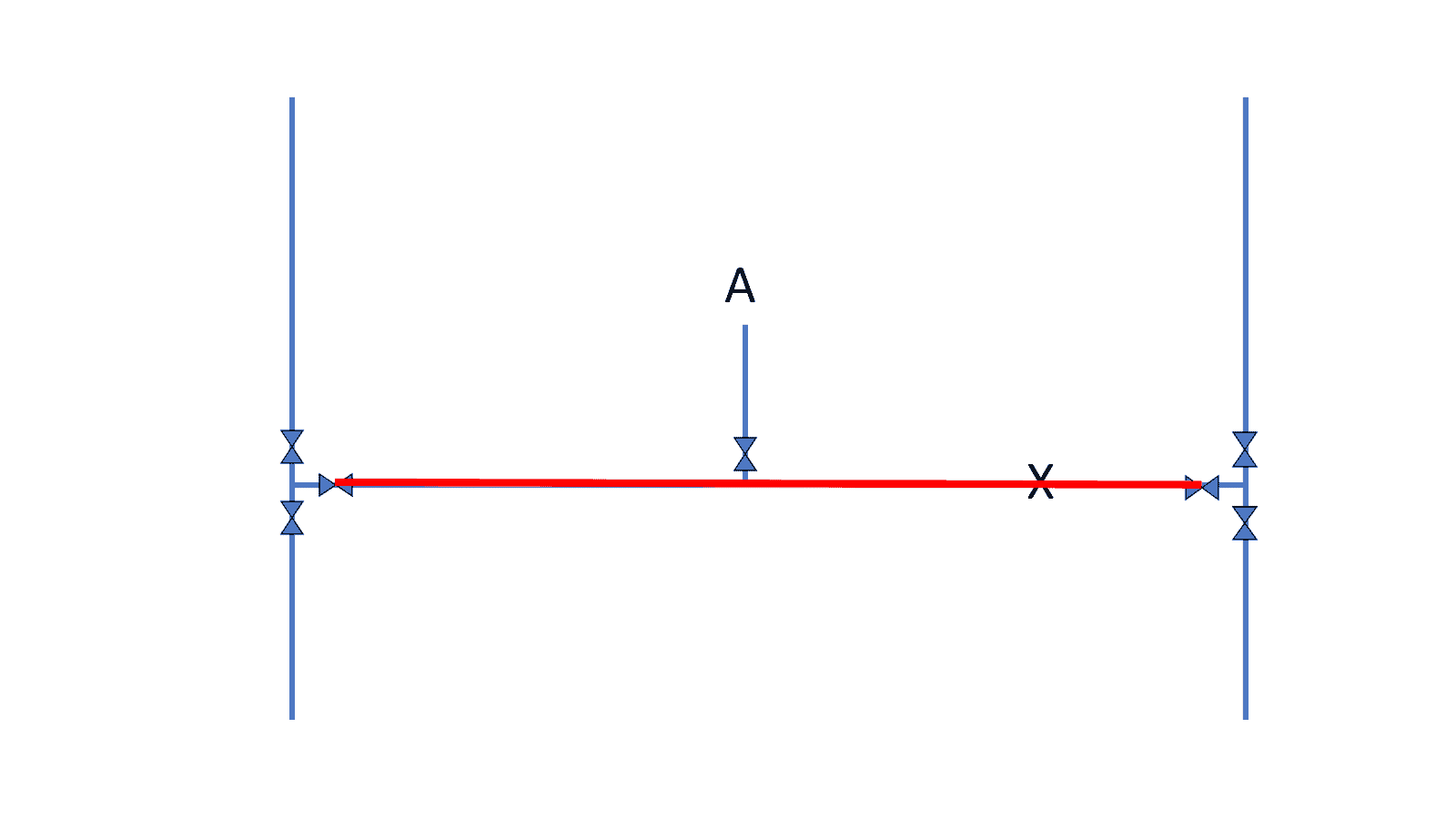

Shown below is a situation where water moves from left to right in a grid of pipes. This looks pretty reliable. Right?

Suppose there is a pipe break at location X. Because of a lack of valves, this one break in a looped system would put all customers to the right of the network out of water. The problem here is the lack of an isolation valve between the two 6-inch pipes. This sort of situation usually occurs when the system evolves gradually over decades and the gradual improvements did not consider this overall picture. This can also happen even if there is a valve between the two 6-inch pipes, but it is not operable for any one of a number of reasons.

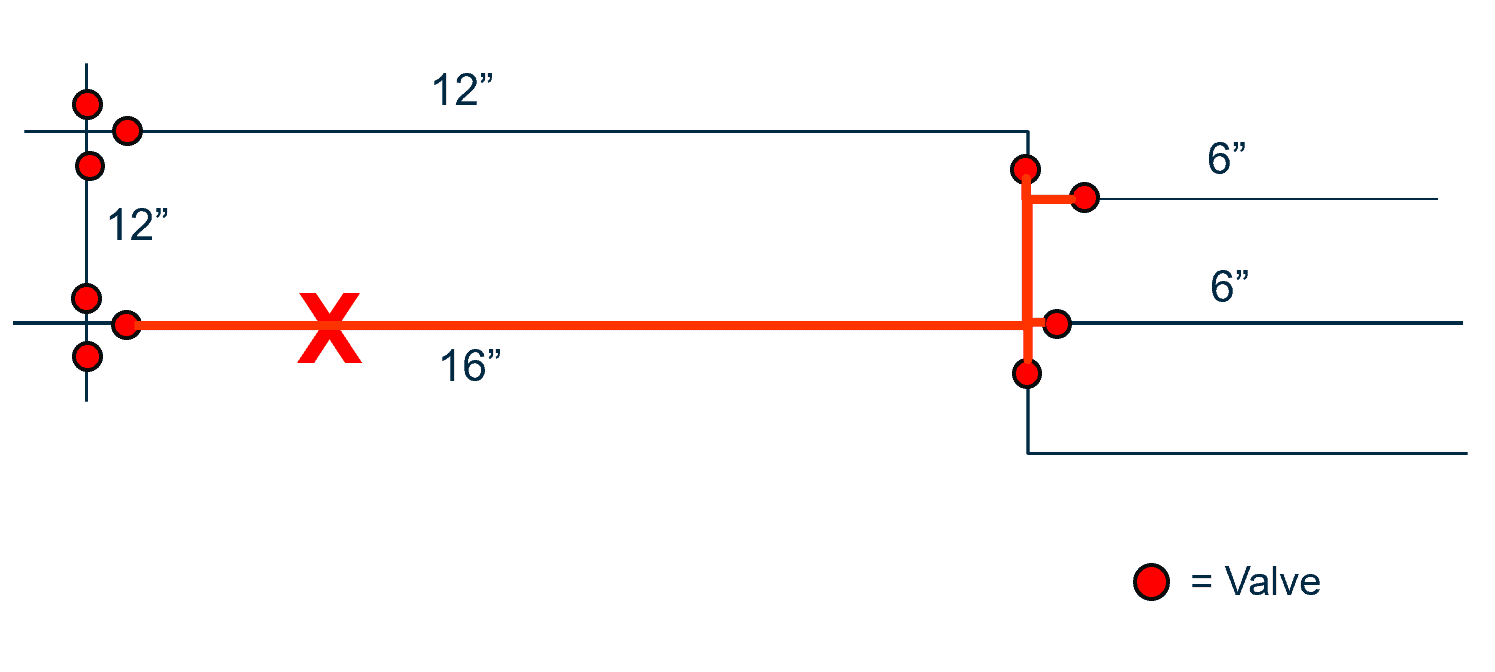

This is what those segments would look like in WaterGEMS.

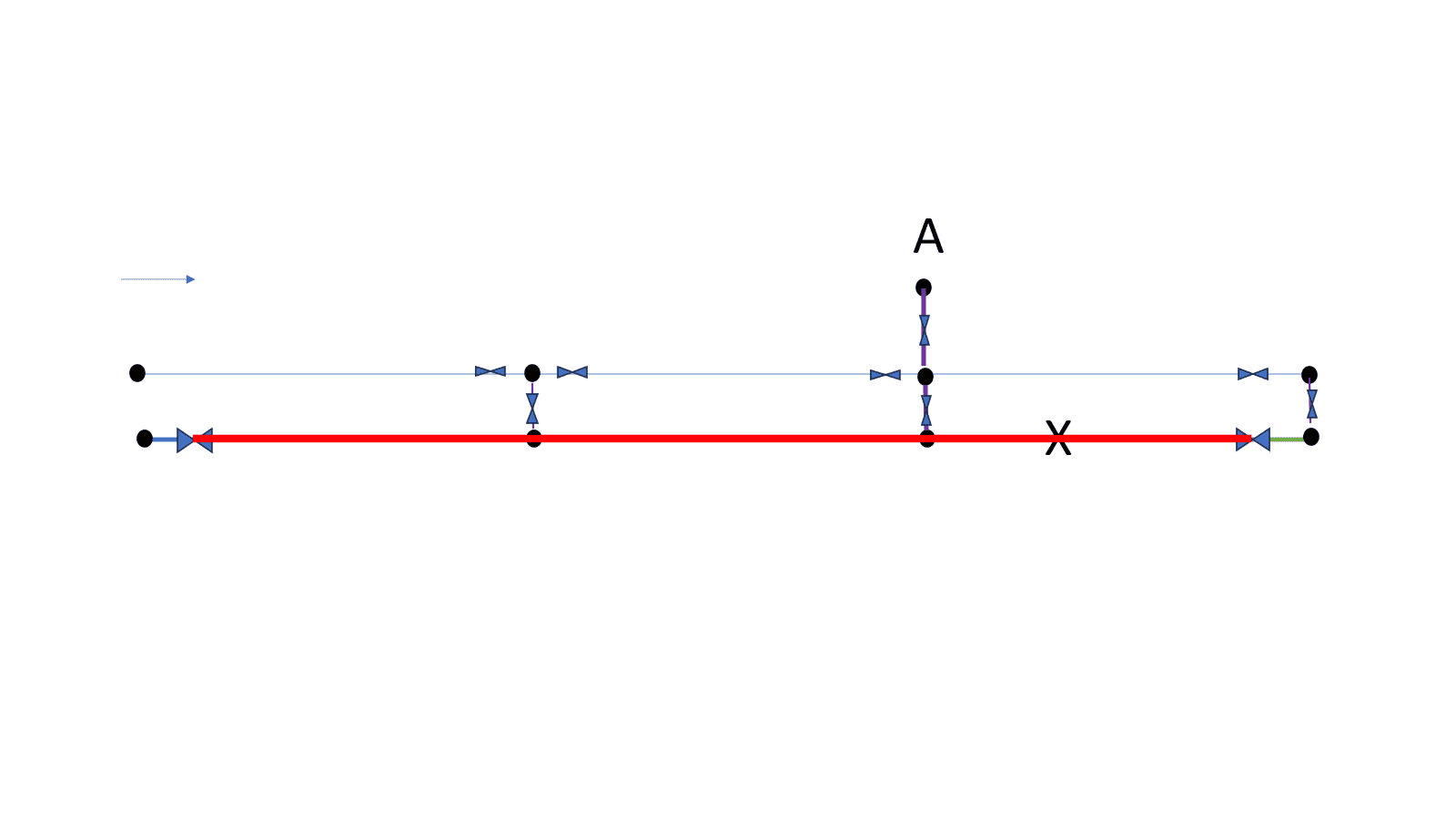

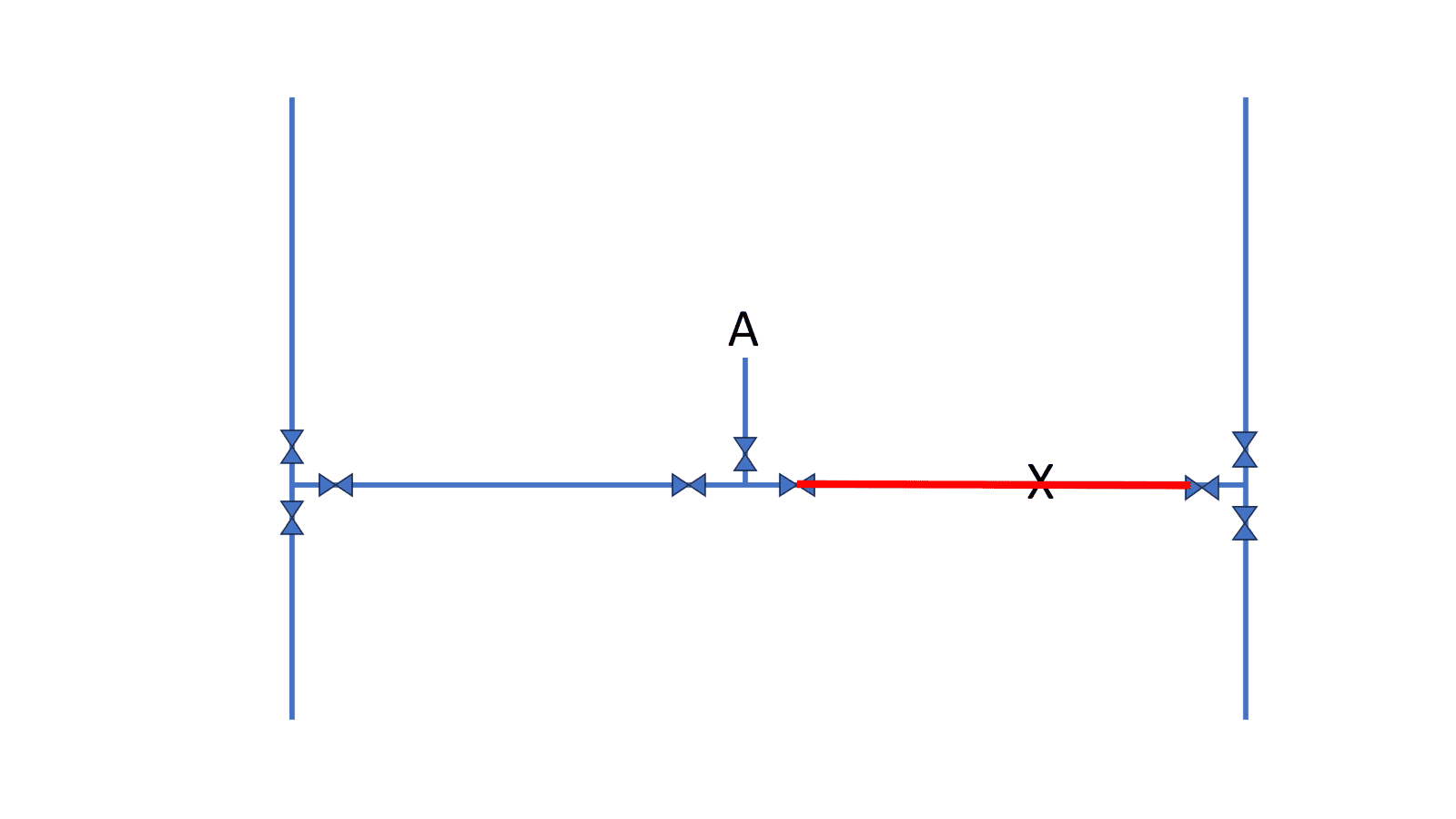

And this is what it would look like if you highlighted the segments downstream of the isolated segment.

The next example is a three-city-block long section of a major transmission main (let’s say 36-inch). It is paralleled by a small distribution main (say 6-inch) that serves customers. Valves on large transmission mains are very expensive so they are used sparingly. There is a critical customer at point A (for example a major industry, wholesale customers, or a hospital). What happens when a pipe break occurs at point X?

You can assume that the green pipe element can simply be removed from the model to simulate what would occur. The model would indicate that critical customer A can be served with no interruption of service while the break is repaired. This, of course, is misleading as it is a segment (red one below), not the pipe element that is closed. Customer A would only be served by the 6-inch pipe, which would likely be inadequate. While for many purposes, including isolation valves in a model is unnecessary, when you are dealing with shutdowns, the location of operable valves is essential. WaterGEMS has a unique way of attaching valves to a pipe without splitting the pipe, helping models run efficiently.

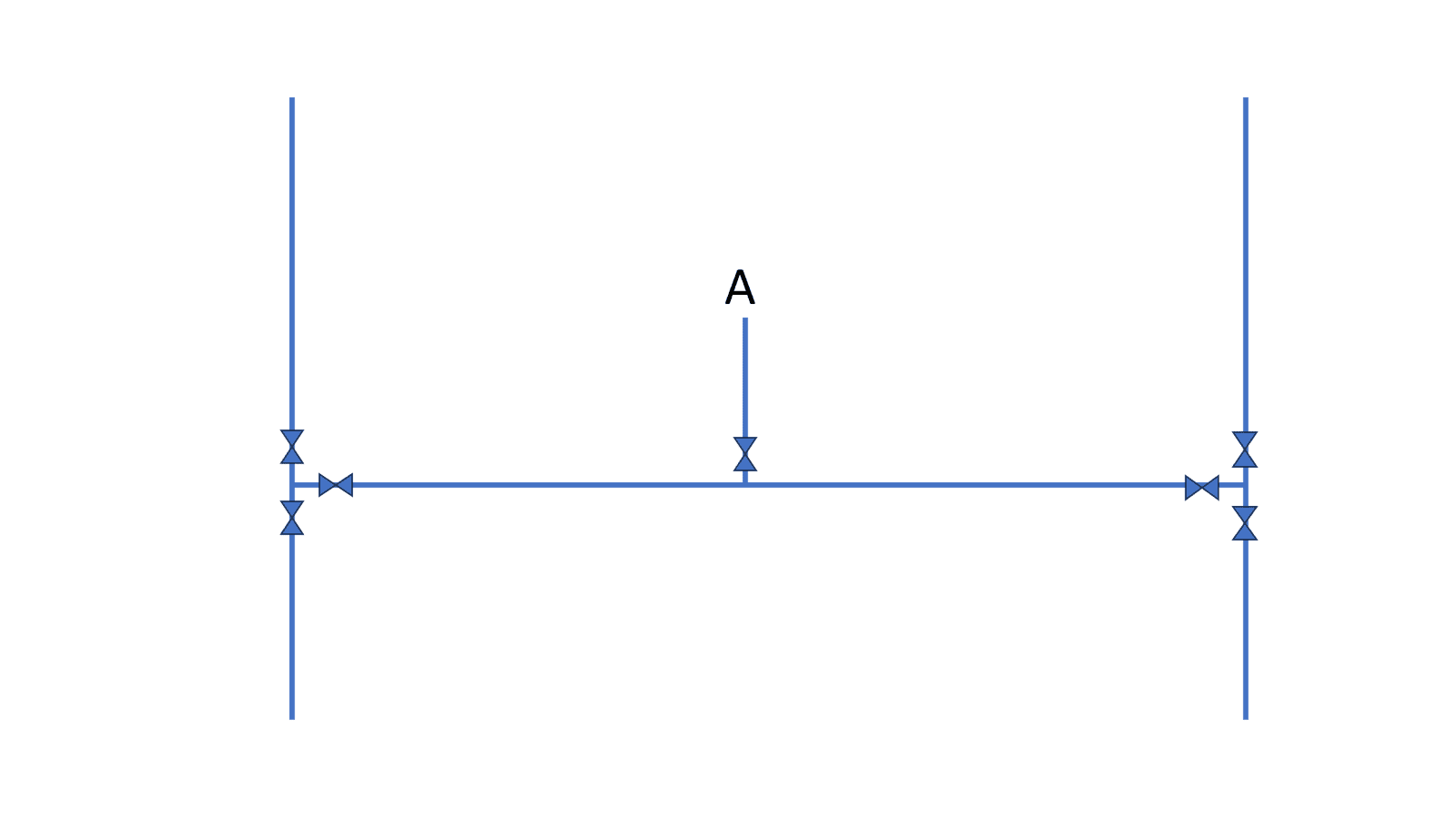

The final example is a critical customer A which is fed from two directions, as shown below.

This looks pretty reliable; however, what happens when the main that serves customer A breaks at point X? The break requires the shutdown of flow from both directions, so customer A is out of service.

In this case, the solution is to create different segments served from different directions such that if one feed is lost, the other will remain connected.

Summary

Isolation valves are critical elements in water distribution systems as they enable system operations and maintenance personnel to isolate segments in the system to minimize the extent of service interruptions. WaterGEMS/WaterCAD/WaterSight provide tools to identify segments, evaluate which ones are likely to cause problems, and analyze alternatives to address an immediate operational problem or scan the system to correct future problems before they occur.

Sources:

Abdel-Mottaleb, N. and Walski, T., 2021, “Evaluating Segment and Valve Importance and Vulnerability,” Journal of Water Resources Planning and Management, 147(5), 0402102, DOI 10.1061/(ASCE)WR.1943-5452.0001366.

Walski, T., 1993, “Water distribution valve topology for reliability analysis”, Reliability Engineering and System Safety, Vol. 43, 21-27.

If you want to look up past blogs, go to https://blog.bentley.com/category/hydraulics-and-hydrology/. And if you want to contact me (Tom), you can email [email protected].