You don’t thread a metro tunnel under a historic city or build foundations in earthquake zones by guessing what’s beneath your feet. In the world’s most ambitious or unique infrastructure projects, Bentley Systems’ PLAXIS software gives geotechnical teams the insights they need to build smarter. Here are six real-world projects where PLAXIS proved its value.

1. Triple Earthquake Simulation, Fukushima, Japan

After the 2011 Great East Japan Earthquake and tsunami in Fukushima, one of the region’s rebuilding efforts involved a one-story factory constructed on silty ground. Takeuchi Construction had used a foundation system called the Tender Net Foundation (TNF), a shallow hybrid design combining grid-shaped soil improvement, a concrete slab, and individual footings.

The foundation held up, even after the site was hit by an earthquake during construction and two more afterward. But was it because of design or luck? Engineers needed to know.

The PLAXIS Effect

Engineers typically had difficulty simulating the behavior of silty ground and the settlement behavior of the foundation following consecutive earthquakes. But using a PLAXIS 3D soil model and seismic records from nearby sensors, engineers simulated the TNF’s performance across all three earthquakes. The model not only matched the observed post-quake settlements, it confirmed something crucial: liquefaction had occurred in the silty ground, challenging long-held assumptions that there was a low risk of this happening.

To examine the TNF’s performance, Takeuchi also modeled a conventional shallow foundation on the same site and found that the TNF had outperformed standard options under real seismic stress.

“Although the analysis was complex, even young engineers were able to conduct it with the excellent constitutive models and user-friendly interface of PLAXIS.”

Yasuo Tomono, manager of research and development, Takeuchi Construction

2. Madrid Metro Line 5, Spain

Engineers used Plaxis 3D for the ground modeling and structural planning for Madrid’s Metro Line 5 project.

Engineers used Plaxis 3D for the ground modeling and structural planning for Madrid’s Metro Line 5 project.Madrid’s Metro Line 5 extension, an estimated €181 million project, involves constructing a critical 1.7-kilometer section to the Adolfo Suárez-Madrid Barajas Airport. The most formidable challenge is an underground crossing that threads a new tunnel between the existing Metro Line 8 tunnel and the M-11 motorway’s embankment. Clearance is just 3 meters at its tightest point, posing a risk to the stability of existing infrastructure.

Initially, a slower, more costly excavation technique was considered, which could have jeopardized project delivery dates, inflated costs, and increased the carbon footprint. The engineering team at Ayesa needed a method that ensured structural safety without sacrificing efficiency or budget.

The PLAXIS Effect

Ayesa deployed PLAXIS 3D to develop a sophisticated soil-structure interaction model. This complex simulation, encompassing over 400 construction phases and all structures within the critical crossing zone, validated the efficient use of a combination of excavation techniques, including the Madrid Traditional Method and cut-and-cover in other sections. Crucially, the model demonstrated that the tunnel could be safely built by excavating the tunnel face in shorter segments (1.25 meters) to minimize ground movement and protect nearby infrastructure. These insights generated substantial savings in costs, time, materials, and carbon emissions.

3. AT&T Stadium, Dallas, USA

AT&T Stadium in Arlington, Texas. Image credit: Wikimedia Commons

AT&T Stadium in Arlington, Texas. Image credit: Wikimedia CommonsThe AT&T Stadium, home to the Dallas Cowboys, stands as the world’s largest covered venue. Its signature retractable roof is supported by two immense steel arches, each weighing over 3,000 tons, spanning nearly 1,300 feet, and imparting 19 million pounds of thrust into their foundations.

The engineering team, including Garry H. Gregory of Gregory Geotechnical, faced a critical challenge of limiting foundation deflection – or movement – to an extremely tight maximum of a half inch, in variable soil conditions. After ruling out several options, they opted for massive, subsurface-boxed diaphragm wall foundations, extending 70 feet deep. The foundations have performed exceptionally well since completion in late 2008, with deflections observed at less than a quarter inch.

The PLAXIS Effect

Years after the stadium’s opening, Gregory undertook a retrospective analysis, using PLAXIS’s advanced finite element analysis software, to validate the original foundation design. The PLAXIS 3D simulation produced an almost identical match to the observed real-world performance, confirming the robustness of the original engineering.

This reanalysis highlighted that if PLAXIS had been available during initial design, it could have seamlessly integrated all load-resisting mechanisms, providing a more comprehensive understanding of developing resistance and potentially allowing for a less conservative design. The work also underscored PLAXIS’s efficiency, demonstrating that complex calculations, achievable in days or weeks using traditional methods, can instead be completed in hours, enabling rapid evaluation of multiple scenarios.

"It was extremely validating to discover an almost identical match in PLAXIS with our original design."

Garry H. Gregory, Gregory Geotechnical

4. Hong Kong's Deepest Subsea Connection

Entrance to the Tuen Mun-Chek Lap Kok Tunnel. Image credit: Wikimedia Commons

Entrance to the Tuen Mun-Chek Lap Kok Tunnel. Image credit: Wikimedia CommonsCosting US$2.33 billion, the Tuen Mun-Chek Lap Kok Link Tunnel, Southern Landfall, is a strategic 5-kilometer, dual two-lane subsea tunnel in Hong Kong. It’s designed to be the city’s deepest and longest. Golder Associates faced complex geotechnical conditions, including alluvium, marine deposits, thick sand fill, and high water pressure.

The PLAXIS Effect

Golder Associates employed Bentley’s geotechnical applications, including PLAXIS 3D, to optimize the tunnel’s . This approach gave them the confidence to reduce the number of required barrettes by 52, while shortening 46 others by an average of 2.8 meters. These efficiencies saved US$16 million, cut construction time by two months, and reduced carbon dioxide emissions by an estimated 1,500 tons. This achievement earned Golder Associates a Bentley Year in Infrastructure Award for Geotechnical Engineering in 2020.

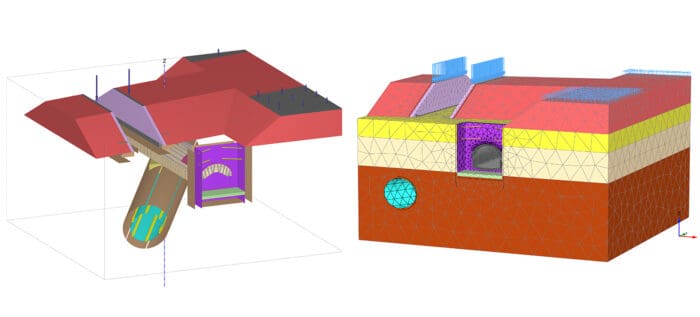

5. Seamless Synergy: Integrating Above and Below Ground Engineering

Historically, structural and geotechnical analyses are often carried out separately. This fragmented approach, relying on manual data transfer, risks inaccurate soil-structure interaction modeling and introduces significant potential for human error, meaning less precise designs and workflow bottlenecks.

The PLAXIS Effect

Hokkaido University researchers bridged this gap by developing a workflow that seamlessly integrates Bentley’s STAAD software, used for structural design, with PLAXIS via Integrated Structural Modeling, Bentley’s framework for connecting tools across disciplines. It allows structural models from STAAD to be imported directly into PLAXIS, enabling engineers to analyze how potential structural loads will interact with the ground.

The integration replaced error-prone Excel transfers and improved data exchange efficiency by 90%, according to the researchers. More importantly, it enabled a tighter, more iterative loop between geotechnical analysis and structural design, allowing engineers to quickly update foundation models as new loads or soil data became available. The project demonstrates the potential for more connected, responsive workflows across disciplines.

"The ISM feature in STAAD is crucial for integrating the superstructure model with geotechnical modeling, enabling users to conduct a comprehensive analysis of the entire project."

Binh Nguyen, research assistant, Hokkaido University

6. Marina Bay Sands, Singapore

Marina Bay Sands in Singapore.

Marina Bay Sands in Singapore.Singapore’s iconic Marina Bay Sands development required one of the country’s largest and deepest urban excavations – a sprawling basement up to 18 meters deep in soft marine clay, immediately adjacent to vital infrastructure. A particularly sensitive area was the Benjamin Sheares Bridge, Singapore’s longest bridge, whose foundations lay close to the edge of the development. The excavation posed a serious risk of ground movement, with the potential to overstress the bridge’s existing connections.

The PLAXIS Effect

Arup engineers used PLAXIS 2D to assess and manage this risk, simulating the soil-structure interaction between the excavation support system and the surrounding ground, with a focus on the bridge abutments. The analysis revealed that lateral ground movement from the deep excavation would indeed exceed safe limits for the bridge’s fixed structural connections.

Instead of attempting to eliminate all movement, an impractical and costly task, the team used the insight from PLAXIS to rethink the problem. They modified the bridge itself, replacing three fixed connections with adjustable pins so that the deck could sufficiently articulate to tolerate the predicted ground movement. This targeted structural adaptation allowed excavation to proceed on schedule while protecting the integrity of the bridge.

Sean O’Neill is a seasoned editor, journalist, and science communicator. He spent 14 years at New Scientist and served as the magazine’s People Editor. Sean has written for Google DeepMind, served as communications lead at the Cambridge Centre for AI in Medicine at the University of Cambridge, and worked as a Science Writer for The Alan Turing Institute in London. You can also find his byline on AI stories and profiles on the Bentley blog.