In the humming Saudi Arabian port city of Jazan, on the Red Sea, grain trucks now rumble through a huge warehouse that once seemed doomed almost from the start. Years before the building was completed, around 2017, cracks laced its concrete slab, walls, and joints. Uneven settlement warped the floor and walls. When heavy cargoes of grain arrived, the damage accelerated. Why had the foundations failed so spectacularly?

Hamzah Al-Hashemi has a ready answer: “Welcome to the Bermuda Triangle of ground engineering.” A geotechnical engineer, Al-Hashemi is the CEO and technical director of GeoStruXer, a company he co-founded in 2023 with his spouse, Dana Al-Faleyleh, a structural engineer. They constitute a personal and professional partnership that’s rare in an industry where their disciplines—ground intelligence and structural expertise—tend to keep a respectful distance. But the combination showed its value at the Jazan warehouse.

The couple set out to uncover what the ground was hiding—and then, using Bentley Systems’ software solutions, designed a warehouse rehabilitation plan so efficient and environmentally sensitive that it went on to win the Bentley Envision Award. The award, given by Bentley Systems as part of its annual Year in Infrastructure and Going Digital Awards (YII), is a special recognition of projects that demonstrate a combination of technical expertise, economic value, and measurable environmental and social benefits.

The food security warehouse (bottom left) at Jazan City Port that was saved by GeostruXer using Bentley software.

The food security warehouse (bottom left) at Jazan City Port that was saved by GeostruXer using Bentley software.Nicholas Cumins, Bentley CEO, said he was proud to highlight the project his YII keynote “as a great example of how engineers can use AI alongside applications like PLAXIS to make smarter decisions and deliver more resilient infrastructure. Truly inspiring work!,” Cumins wrote on LinkedIn.

Before the couple arrived, the warehouse owners had searched for a way to halt the sinking, but every proposal offered extensive, overdesigned solutions that demanded thousands of deep micropiles, thick concrete slabs, and prohibitive cost.

During those wilderness years for the Jazan warehouse, Al-Hashemi completed his master’s in geotechnical engineering at King Fahd University in Saudi Arabia and joined a Bahrain firm launching a new micropiling division. For the uninitiated, micropiles are steel bars or tubes that are drilled down into firmer ground and concreted, or grouted, into place. They support buildings in places where the surface soil is too weak or loose, or where space is tight for larger solutions. Al-Hashemi’s first assignment was ambitious: Help design a unique micropiled “raft” foundation on reclaimed land for a 70,000-square-meter project called Al-Madina Al-Shamaliya (AMAS, or “The Northern City”) in Madinat Salman, Bahrain. “We believed it would be the world’s largest micropile post-tension raft in the world,” he says. “We contacted Guinness World Records, but perhaps unsurprisingly, they did not have that category.”

Working across the office was Al-Faleyleh. “That project was where we met,” Al-Hashemi says. “I was designing the ground, she was designing the concrete raft, though our relationship started before discussing any technical things, by sharing meals.” But they clicked professionally, too, noting how often geotechnical and structural work were treated as separate worlds, leading to waste, over-design, or outright failure. They married soon after.

As Saudi Vision 2030 unleashed a wave of megaprojects, demand for local engineering expertise soared. So after a year in Cyprus, where Al-Hashemi was working with InSAR satellite data—which measures ground movement over time with millimeter precision—the couple returned to the Gulf and heard about a problematic warehouse in Jazan.

Sensing a potential proving ground for their ideas, Al-Hashemi and Al-Faleyleh founded GeoStruXer in late 2023. They aimed to unite geotechnical and structural design under one roof, harnessing data and digital modeling to show how a sustainable design approach could solve even the region’s most stubborn ground problems.

Jazan’s ‘Bermuda Triangle’

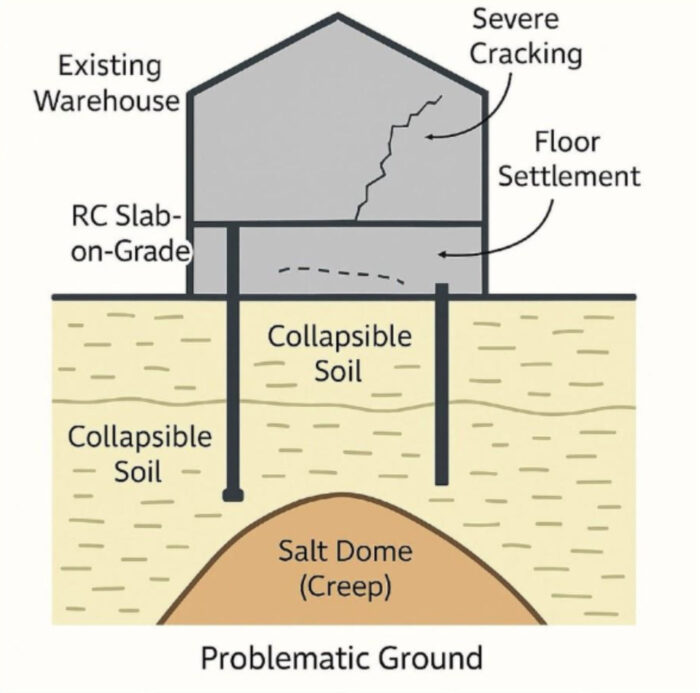

If ever a region existed to test the thesis, it is Jazan. The city sits on what’s known as sabkha soil, salt-rich coastal flats that can not only collapse but also corrode foundations. Seismicity and extreme heat only compound the risk. “An old note by the U.S. Geological Survey team suggested that Jazan better be evacuated and rebuilt virtually anywhere else,” Al-Hashemi points out.

By the time the facility at Jazan Port had been completed in 2017, the beleaguered structure showed 170 millimeters (6.7 inches) of differential deformation, or uneven settling, throughout the years. Unfortunately for GeoStruXer, the owner had no reliable historical data as to how this settlement had progressed. The owner had commissioned four soil reports, but they all conflicted with each other, and none came close to explaining the magnitude of the deformation.

Al-Hashemi fed the most pessimistic soil data into PLAXIS 3D, Bentley’s advanced 3D software that lets engineers model how soil, foundations, and structures interact. The model couldn’t fully explain the problem, accounting for just a portion of the 170 millimeters observed. “There had to be something else, some time-dependent process,” he recalls. Reviewing old geological reports, he made a key discovery: The entire warehouse region was above a 5-kilometer salt dome—a vast body of ancient rock salt that moves, deforms, and dissolves when it meets groundwater, quietly dragging everything above it out of alignment.

It was a big problem. “Once encountered, you cannot ‘solve’ a salt dome; you cannot overcome it. You have to live with it,” says Al-Hashemi. “But you have to understand how it is behaving.” And when a salt dome starts dissolving and forms an underground cavity, it will gradually swallow the sand above it.

What lies beneath? A potent combination of conditions that conspire to undermine all but the most comprehensive engineering approach.

What lies beneath? A potent combination of conditions that conspire to undermine all but the most comprehensive engineering approach.To explore whether they could live with the salt dome, Al-Hashemi would need a time machine. He would find one in the sky. “InSAR satellite data from an office in Cyprus lets us travel back in time,” he says. Data from 2017 onward revealed not just a problem under one unfortunate warehouse, but a city-scale descent. “When we obtained the data, we saw not only our building was having an issue, but actually the whole city was settling, by about 20 to 25 millimeters per year in various locations.”

How GeostruXer Predicted The future

With this valuable data, the team used a simulation model in PLAXIS 3D, typically used in the mining industry, because the voids created by salt domes often serve as repositories for petrochemicals. (For completists, it was the Norton Double Power Creep (N2PC) model for salt deformation.) The team adjusted the creep parameter—how much the soil deforms—until their simulation of the ground movement under the warehouse matched InSAR records. Guesswork was banished, leaving behind a site-specific, time-aware ground model. Now they had a firm idea of how the ground would behave under static and seismic load over time.

“We had calibrated the past, calculated the present, and that meant we could predict the future,” says Al-Hashemi.

The team then set about designing a right-sized rehabilitation project for the warehouse, not an overdesigned foundation fortress. Armed with a calibrated ground model, the GeoStruXer team turned to artificial intelligence (AI) to automate what would otherwise have taken months of manual engineering. Within PLAXIS, the algorithm varied over a dozen geotechnical parameters in soil layers and micropiles, including stiffness and creep, and ran numerous simulations to map how potential foundation designs would respond. It revealed the “sweet spot” of about 800 micropiles. It was a striking contrast to the previous rehabilitation design, which had called for 2,700.

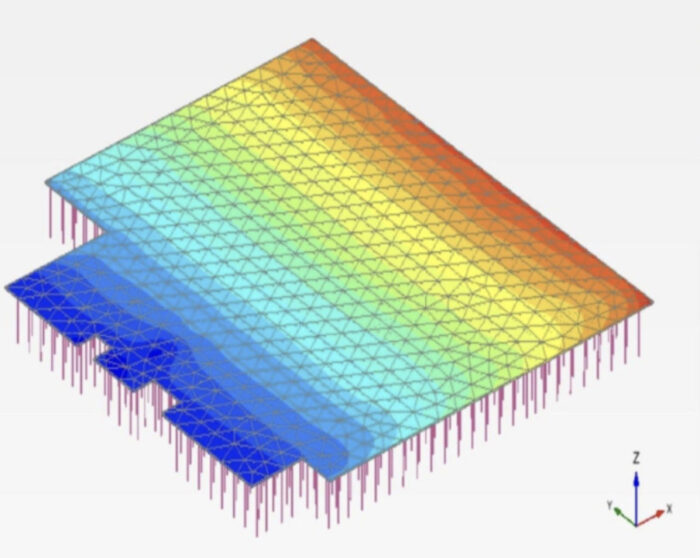

A PLAXIS 3D model showing the extent of the expected temporary deformation of the completed foundation design in the event of an earthquake.

A PLAXIS 3D model showing the extent of the expected temporary deformation of the completed foundation design in the event of an earthquake.To validate the digital model in the field, engineers installed a test micropile on site and performed a plate-load trial, pushing until failure. The measured soil behavior and the PLAXIS simulation matched almost perfectly—a rare degree of certainty in ground engineering—giving the final green light to rebuild.

With the ground model validated, attention turned to the structure—Al-Faleyleh’s domain. Her solution, designed using Bentley’s RAM Concept software, was to pair and evaluate the micropiled foundation with a new post-tensioned concrete raft. This system is stronger and thinner than a conventional slab thanks to high-strength steel tendons tensioned after the concrete is poured. Typically, in such designs, rafts are treated as “floating” on the foundations, carrying little of the structural load. But thanks to GeoStruXer’s final validated ground model, Al-Faleyleh could safely design a system where the micropile foundations and raft shared the load roughly 70/30, reducing materials and boosting sustainability without compromising performance.

The advantages over the previous design were extraordinary. GeoStruXer cut material use by more than 70% and saved 1,200 tons of steel by using just 779 shorter, lighter micropiles rather than the original 2,700 longer and heavier ones. They cut the project’s embodied carbon emissions by about 80%. The value-engineered design also slashed more than USD $2 million from the foundation cost. The ongoing deformation in the now-rehabilitated warehouse is just one-sixteenth of its previous rate, well within acceptable limits.

The approach worked so well because the data, modeling, and design tools spoke the same language. Remote sensing revealed the ground’s historical movement. PLAXIS 3D turned that history and other data into a calibrated, predictive model. RAM Concept translated the ground response into an optimized, post-tensioned slab that efficiently shared load with the micropiles.

Blueprint for the future

Al-Faleyleh is blunt about the risks of ignoring the ground. “Too often, structural engineers just open the geotechnical report, take a single bearing-capacity value, run our structural model, and that’s it, so projects are overdesigned or under-designed,” she says.

Al-Hashemi knows the blind spot firsthand. “I spent two years persuading the Bahrain Society of Engineers just to recognize me as a geotechnical engineer,” he says. “But finally, I now exist.”

Today, GeoStruXer is helping change that mindset. Both engineers are Bentley Qualified Trainers—Al-Hashemi in PLAXIS, Al-Faleyleh in RAM Concept—using real projects to teach students how coupled design works in practice.

Al-Hashemi also founded the Gulf Geotechnical Engineers platform, which now boasts about 3,000 engineers across the Middle East, and co-chairs the International Geotechnical Innovation Conference. He also hosts webinars and other events. The goal is simple: normalize geotechnical–structural collaboration so that right-sized design becomes the norm.

Today, the Jazan warehouse is back in full operation—stable, monitored, and understood. For the first time, the owner knows how it will behave over the coming decade. GeoStruXer’s breakthrough was not a single discovery, but the way it linked everything together: soil reports that revealed fragments of the truth, satellite data that showed the ground’s historical movement, and geotechnical and structural models that translated it all into a confident, sustainable design.

That unity of data and design, soil and structure, love and family, is what defines GeoStruXer’s work. Their Jazan project may become a blueprint for the salt-dome and sabkha regions of the Middle East: Calibrate the past, calculate the present, predict the future—and build only what’s truly needed.

Hamzah Al-Hashemi and Dana Al-Faleyleh, co-founders of GeoStruxure and proud winners of Bentley’s Envision Award at 2025’s Year in Infrastructure Awards.

Hamzah Al-Hashemi and Dana Al-Faleyleh, co-founders of GeoStruxure and proud winners of Bentley’s Envision Award at 2025’s Year in Infrastructure Awards.