Pressure vessel design is demanding. Engineers must balance safety, precision, and strict code compliance, often under tight deadlines. Traditional workflows involve hours of manual calculations, drawing, and rework. The process is time-consuming, costly, and prone to error, especially when working with complex designs like shell and tube heat exchangers.

But what if that pressure could turn into progress? That’s precisely what AutoPIPE Vessel offers, enabling engineers to achieve greater productivity, cost-effective manufacturing, improved project collaboration, and truly optimized pressure vessel designs.

Take, for example, a global engineering firm designing a high-pressure heat exchanger for a petrochemical plant. Traditionally, this would take weeks of manual iteration and code checks. But with AutoPIPE Vessel, the team reduced design time by over 40%, identified material savings early, and collaborated effortlessly across continents.

With AutoPIPE Vessel, you’re not just keeping up—you’re getting ahead.

Explore seven ways that AutoPIPE Vessel is reshaping the future of pressure vessel engineering:

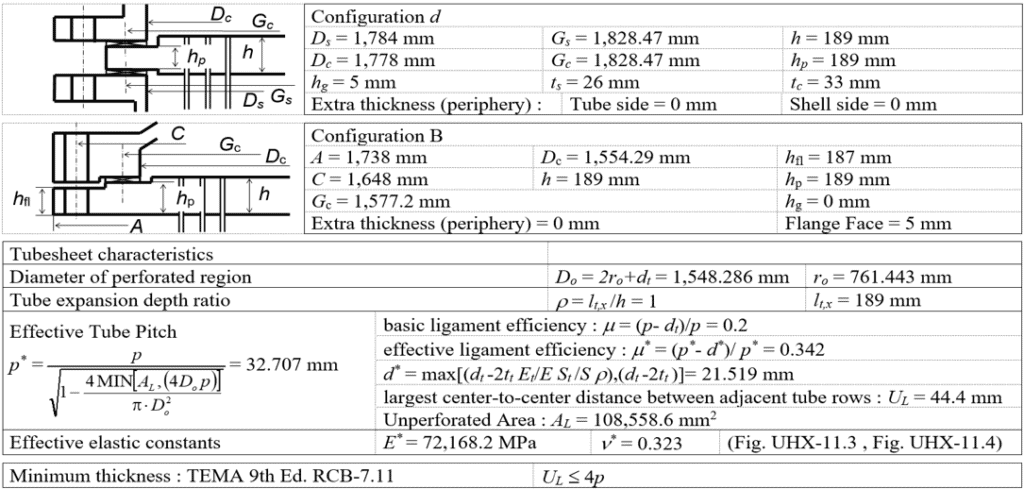

1. Automated design: Say goodbye to manual calculations and design delays. AutoPIPE Vessel acts as your smart assistant, instantly filling in missing values and guiding you through design and cost estimation with advanced automation. It ensures your designs are accurate, efficient, and fully code-compliant, without the hassle of manual iterations.

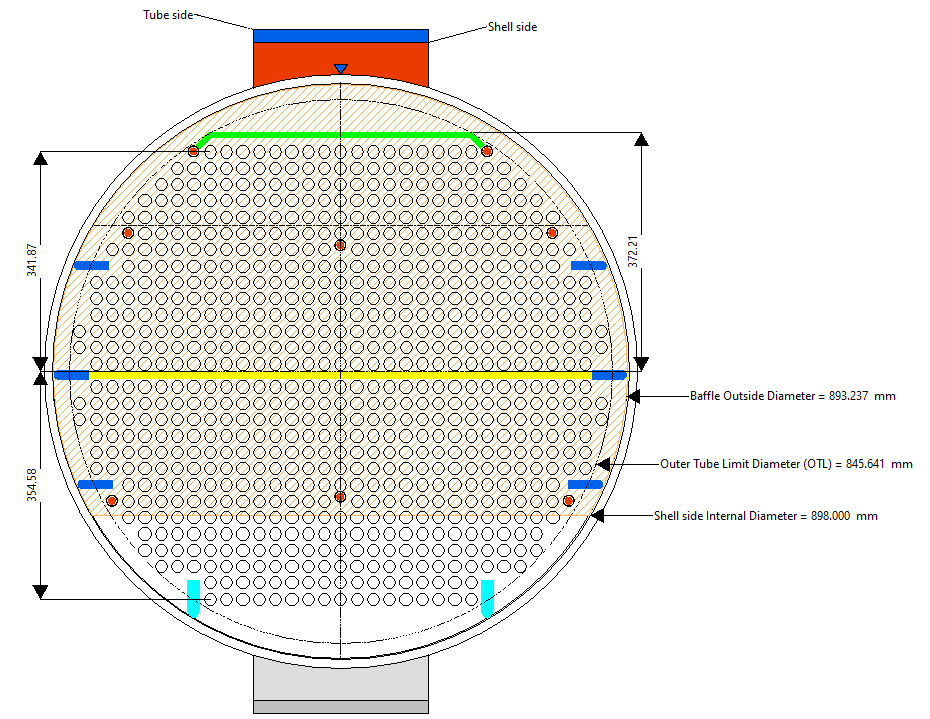

2. Effortless bundle layout design: AutoPIPE Vessel streamlines complex tube bundle design with intuitive tools. Whether it’s adjusting tube pitch, sealing rods, or impingement plates, you can create and customize layouts with just a few clicks—automated or manual, your choice.

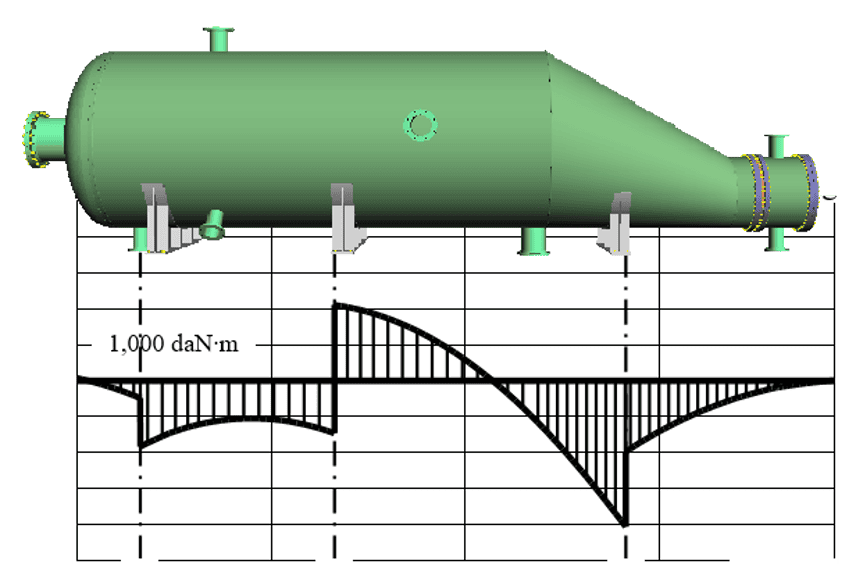

3. Robust support calculations: AutoPIPE Vessel ensures vessel stability with advanced finite element analysis, handling even complex, asymmetrical designs. It checks support legs under various loads, validates against industry codes, and calculates natural frequencies for seismic readiness. Plus, its Summary of Changes feature highlights design improvements for better quality and cost efficiency.

4. Extensive material database: With over 2,000 pre-loaded materials, AutoPIPE Vessel makes it easy to find, customize, and apply material properties. Built-in data such as thermal expansion and elasticity streamlines your workflow and reduces errors—boosting both speed and accuracy.

5. Clear, customizable reports: AutoPIPE Vessel delivers easy-to-read reports with visuals, code references, and step-by-step analysis. Customize headers, footers, and cover pages to save time while gaining deep insights into your vessel’s performance and durability.

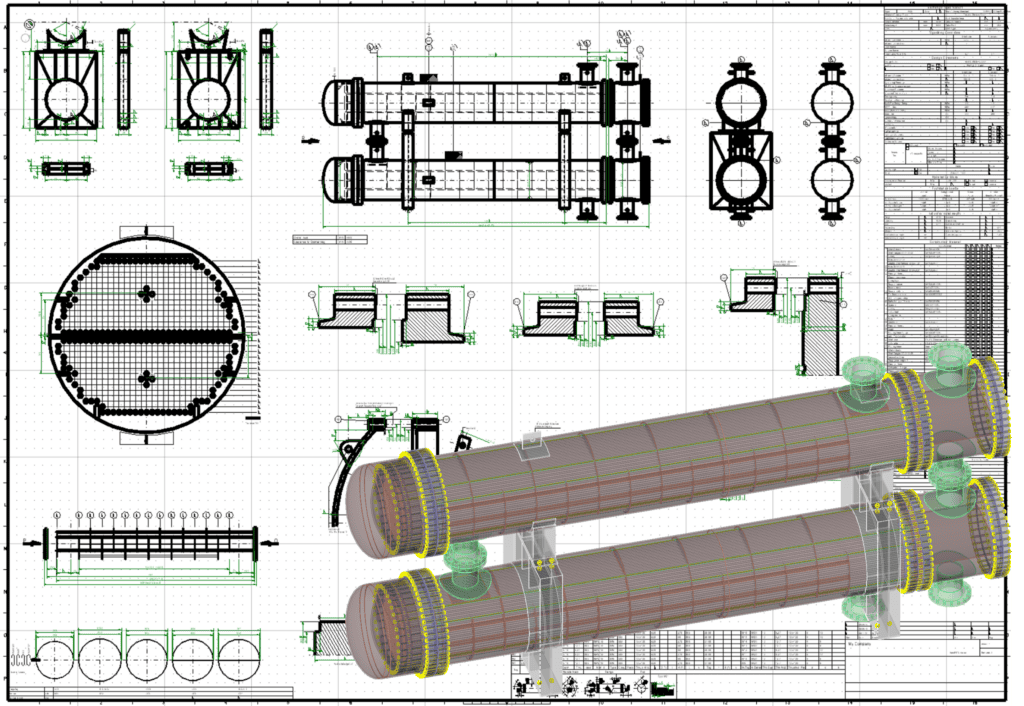

6. Instant 2D and 3D drawings: AutoPIPE Vessel slashes drawing time with instant, customizable 2D and 3D outputs. Export in common formats including .dwg, .dgn, IFC, or SolidWorks, and generate fully detailed engineering drawings to improve accuracy, speed, and project profitability.

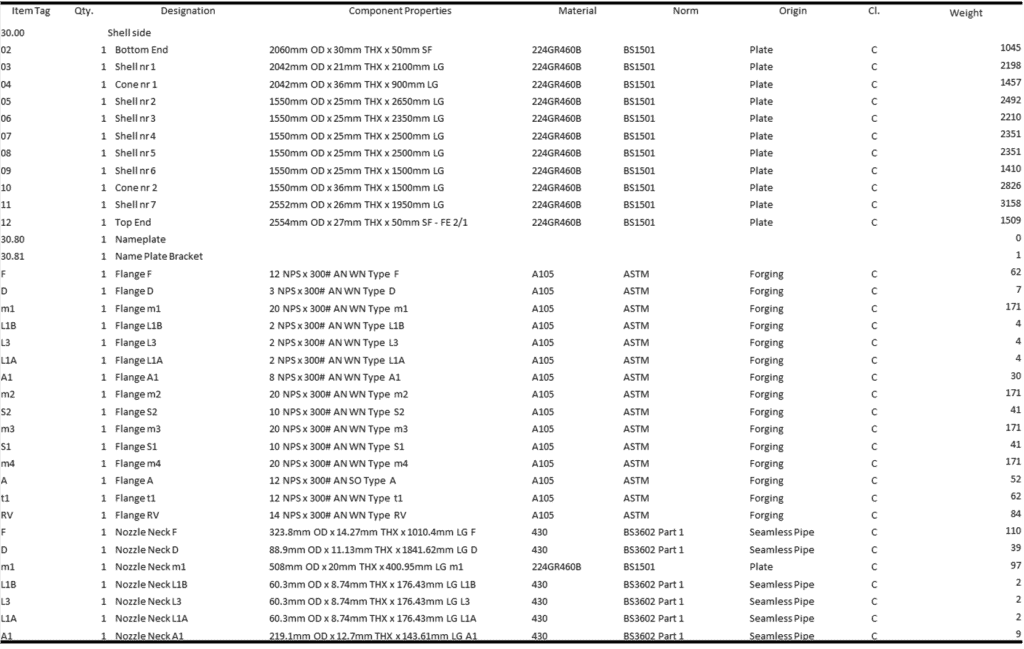

7. Automated BOMs: AutoPIPE Vessel instantly generates detailed bills of materials in Excel—complete with materials, weights, and references—saving hours of manual work and ensuring alignment with your company’s standards.

AutoPIPE Vessel automatically calculates and optimizes thicknesses, updates the 3D model in real time to check clearances, and reduces manual drawing time and rework—delivering accurate and safe designs using fewer resource hours.

- Cristian Peri, Technip