SYNCHRO 4D Powering the World’s First Iron Ore Briquette Plant

Organization: Deloitte and Vale

Project Name: SYNCHRO 4D Powering the World’s First Iron Ore Briquette Plant

Location: Vitória, Brazil

Project Phase: Construction

Expected Completion Date: December 2023

Estimated Project Cost: USD 340 million

Bentley Software: SYNCHRO 4D, iTwin Capture, Cesium

Project

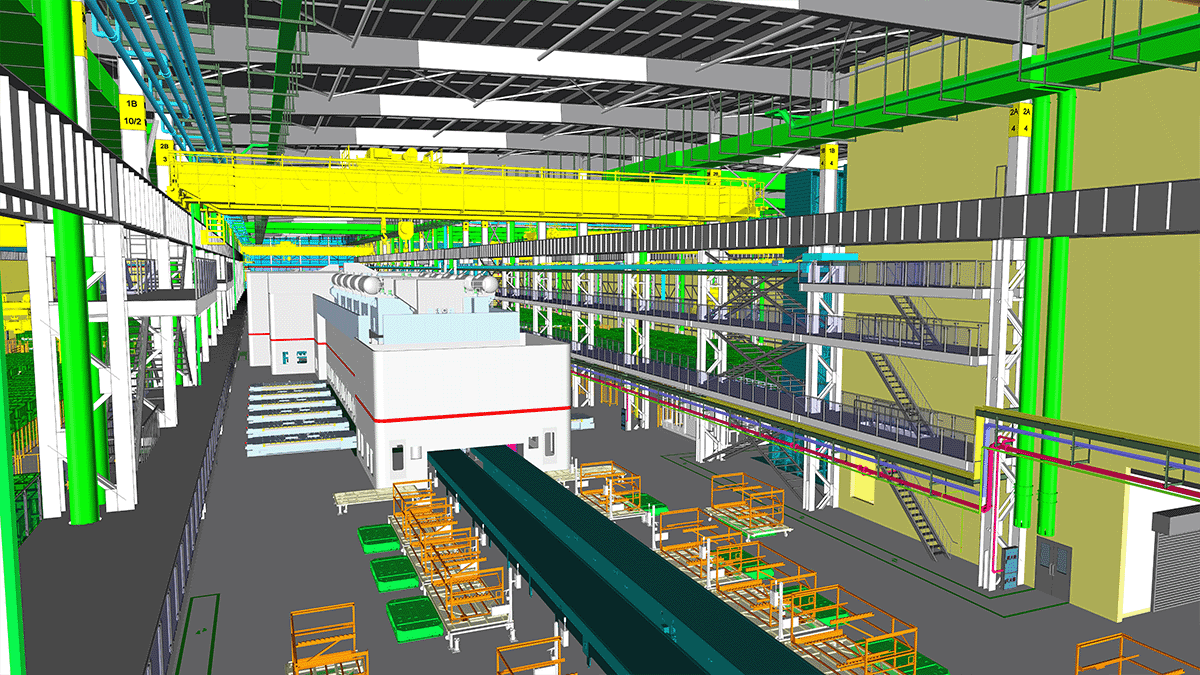

Vale’s iron ore briquette plant in Vitória, Brazil is the world’s first facility of its kind, designed to deliver a product that can help reduce CO₂ emissions in steelmaking by up to 10%. As part of Vale’s global decarbonization strategy, the project transforms a former pellet plant into a high-tech, sustainable production site. Deloitte led the digital execution, integrating AWP, BIM, and lean methodologies with Bentley’s SYNCHRO 4D as the central software.

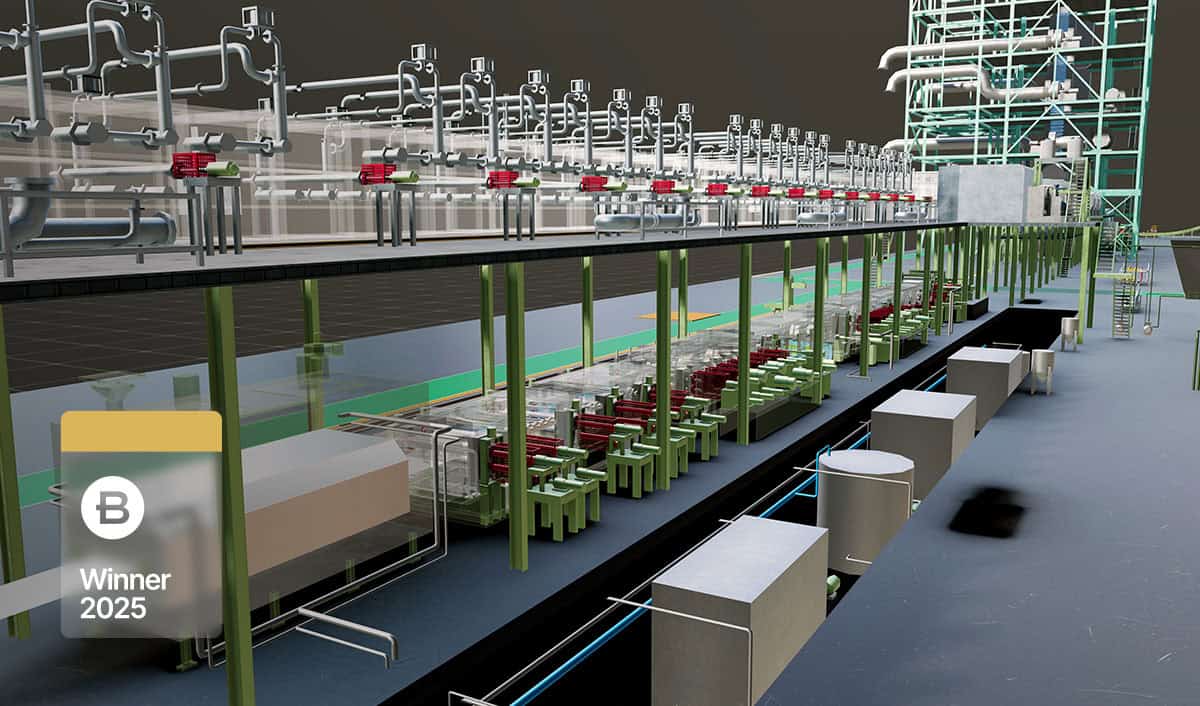

The team coordinated over 1,500 work packages through visual planning, improving schedule accuracy by 41% and cutting engineering approval cycles by 10 days. Advanced 4D simulations enabled safer field operations and the identification and removal in advance of more than 2,000 constraints. AI-powered transcription of technical videos streamlined communication and reduced reporting time by more than 50%.

This project sets a new benchmark for digital transformation in industrial construction and now serves as the reference model for future iron ore briquette plants across Vale’s global portfolio.

Facts

- Vale’s plant is the world’s first to produce iron ore briquettes, an innovative product can help reduce greenhouse gas emissions in steel production by up to 10%, supporting global industrial decarbonization efforts.

- Visual planning with SYNCHRO 4D construction software improved schedule accuracy by 41% and cut engineering approval cycles by 10 days.

- 4D simulations enabled the identification and removal of more than 2,000 constraints, enhancing safety and reducing on-site conflicts.

“Bentley’s SYNCHRO 4D served as the digital backbone for coordinating over 1,500 activities in the construction of Vale’s first iron ore briquette plant. By consolidating CWPs, schedules, and 4D models in a uniform environment, the tool enabled connected and collaborative site management, supporting strategic decisions with traceable, shareable, and visual data. Its implementation marked a turning point in the digital transformation of industrial capital projects.”

Eduardo Lavocat, Senior Manager, Deloitte Infrastructure & Capital Projects

Solution

SYNCHRO 4D served as the core planning software for planning, execution, and monitoring in the construction of Vale’s first briquette plant. Led by Deloitte, the project team implemented AWP, BIM, and lean methodologies, integrating over 40 construction work areas (CWAs) and 1,500 construction work packages (CWPs) into SYNCHRO to enable dynamic, collaborative planning. Despite limited model detail and digital maturity, SYNCHRO 4D provided a unified environment for constructability analysis, risk simulations, and schedule integration.

During engineering, SYNCHRO supported logistics planning and constructability reviews. In execution, it enabled detailed tracking of service fronts and material deliveries. For commissioning, the software visualized progress and flagged outstanding issues, improving predictability. The Appearance Profile feature allowed granular monitoring across engineering, procurement, and construction phases. SYNCHRO also facilitated realistic lifting simulations via Unreal Engine, enhancing safety in high-risk operations.

Phased tracking, like ring-by-ring tank assembly, was supported through custom subdivisions and Excel-based updates. Integration with Power BI dashboards enabled real-time visual progress tracking and early deviation detection. AI-powered transcription of SYNCHRO-generated videos added traceability and reduced reporting time by over 50%.

In total, SYNCHRO 4D coordinated over 1,500 activities, improved schedule accuracy by 41%, and helped reduce the supply total lead time by 15%. Its implementation marks a turning point in digital project delivery and establishes a scalable model for future iron ore briquette plants worldwide.

Outcome

The project achieved a 41% increase in schedule accuracy and cut engineering approval cycles by 10 days through SYNCHRO 4D’s visual planning. AI-powered transcription reduced reporting time by over 50%. 4D simulations enabled the identification and removal of more than 2,000 constraints, enhancing safety and minimizing conflicts. Despite a six-month delay in engineering completion, proactive use of AWP and 4D replanning prevented rework and stoppages, ensuring the project was delivered on schedule. The success of this pilot plant has established a scalable model for future iron ore briquette plants worldwide.

Software

SYNCHRO 4D Pro was key for planning, execution, and monitoring. It was used for 4D simulations, sequencing, risk analysis, and visual tracking of over 1,500 activities.

iTwin Capture was used to integrate reality data (e.g., drone imagery and point clouds) into the 4D model for immersive reporting and progress validation.

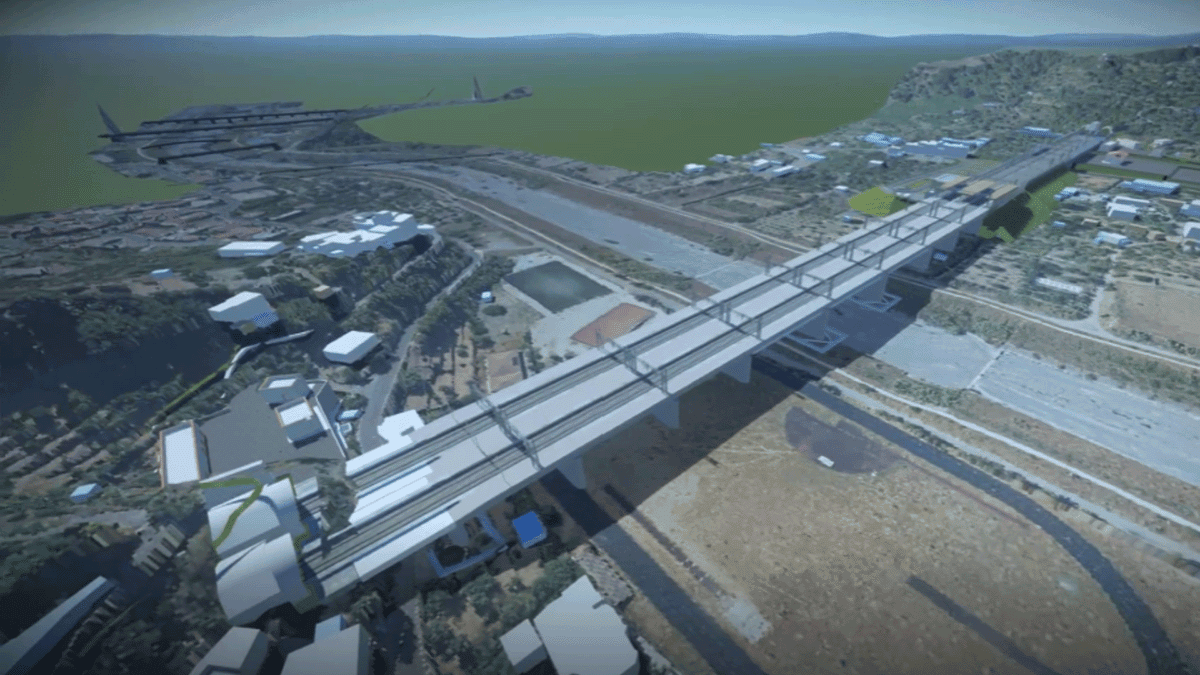

Cesium supported geospatial modeling and visualization, enhancing spatial context for planning and execution.

Ready to reduce emissions through smarter construction? See how SYNCHRO 4D supports low-carbon project delivery.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.