Italferr’s AI-Powered Digital Twin for Serravalle Tunnel

Organization: Italferr S.p.A.

Project Name: Digital Twin Inspection and Maintenance System for the Serravalle Tunnel

Location: Serravalle Tunnel, part of the Terzo Valico dei Giovi railway between Genoa and Milan, Italy

Project Phase: Ongoing digital modernization

Expected Completion Date: Part of a long-term railway enhancement initiative

Bentley Software: iTwin Capture, iTwin Experience, OpenRail, OpenTunnel, ProjectWise

Additional Context: As part of the Terzo Valico dei Giovi railway development, Italferr introduced an AI-powered digital twin to automate tunnel inspections, reducing inspection time by 15.9%, saving 264 work hours, cutting field interventions by 60%, and lowering operational risk by an estimated 70%.

Project

As part of the Terzo Valico dei Giovi, a strategic railway connecting Genoa and Milan, Italferr focused on innovating the monitoring and maintenance of the Serravalle Tunnel. The project’s core challenge was to move beyond traditional, time-consuming inspection methods to a more efficient and reliable digital process. Italferr sought to create an advanced digital system using AI and laser scanning to automatically detect structural defects. The goal was to improve safety, reduce maintenance costs, and extend the useful life of the infrastructure.

Facts

- Work hours saved: 264

- Time reduction compared to traditional plan: 15.9%

- Reduction in field interventions: 60%

- Reduction in operational risk: 70% (estimated)

“The integration of Bentley software into the Serravalle Tunnel experimentation project represented a paradigm shift in infrastructure management. Thanks to advanced modeling and collaboration between the various digital tools, we have achieved finer control, reduced uptime, and an overall improvement in project quality.”

- Rossella de Robertis, BIM Coordinator, BIM Construction & Field, Italferr

Solution

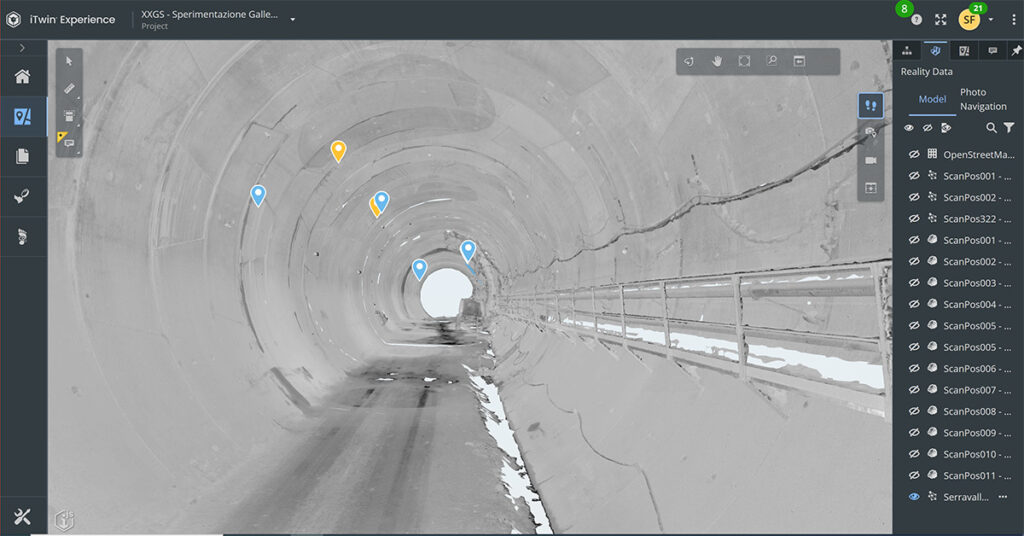

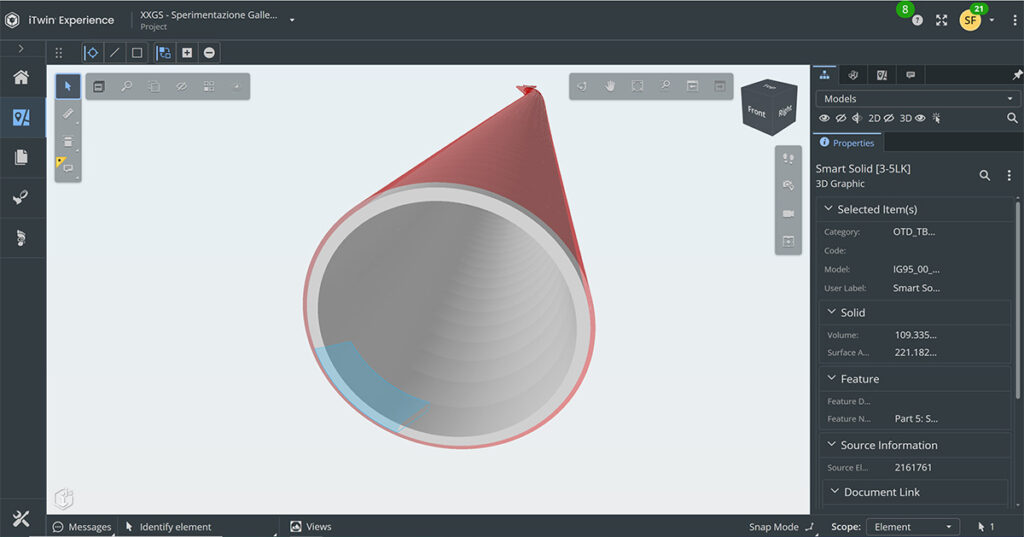

Italferr implemented a sophisticated digital twin workflow using the Bentley iTwin platform and design applications. The process began with Bentley’s iTwin Capture Manager, which processed data from laser scanners to create a comprehensive point cloud of the tunnel. Using Bentley’s OpenRail and OpenTunnel, Italferr then developed two precise digital models: one for design and one for the as-built conditions. The most innovative aspect was the development of advanced AI algorithms to automatically recognize structural defects from the digital twin data. The iTwin platform provided a collaborative environment for all stakeholders to access and share information in real-time.

Outcome

The creation of an AI-powered digital twin for the Serravalle Tunnel has transformed Italferr’s approach to infrastructure management, delivering quantifiable improvements in efficiency and safety. The digital workflow reduced the time required for inspection activities by 15.9%, compared to the traditional plan, saving 264 work hours. The ability to use remote surveys and predictive maintenance reduced the need for physical field interventions by 60%, improving safety for personnel. This new approach to monitoring and maintenance resulted in an estimated 70% reduction in operational risk, minimizing the chance of sudden service disruptions. This innovative project serves as a concrete step toward a more sustainable and resilient infrastructure model by extending asset life and ensuring safer, more reliable operations.

Software

- iTwin Platform (Capture, Experience): Enabled the creation and visualization of the tunnel’s digital twin.

- OpenRail and OpenTunnel: Created precise 3D models of the tunnel for both design and as-built conditions.

- ProjectWise: Managed project data and workflows.

Discover how Bentley solutions are transforming tunnel maintenance. Start with the AI-powered Bentley iTwin platform, OpenRail, and OpenTunnel.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.