YII Winner | Baosteel Engineering & Technology Group’s Digital Twin–Driven Upgrade of the Baoshan Iron and Steel Plant

Organization: Baosteel Engineering & Technology Group

Project Name: Baoshan Iron and Steel Plant Structural Optimization and Upgrade

Location: Shanghai, China

Project Phase: Completed (delivery achieved in six months, half the conventional schedule)

Estimated Project Cost: Not specified (saved RMB 49 million through cost reductions and predictive maintenance)

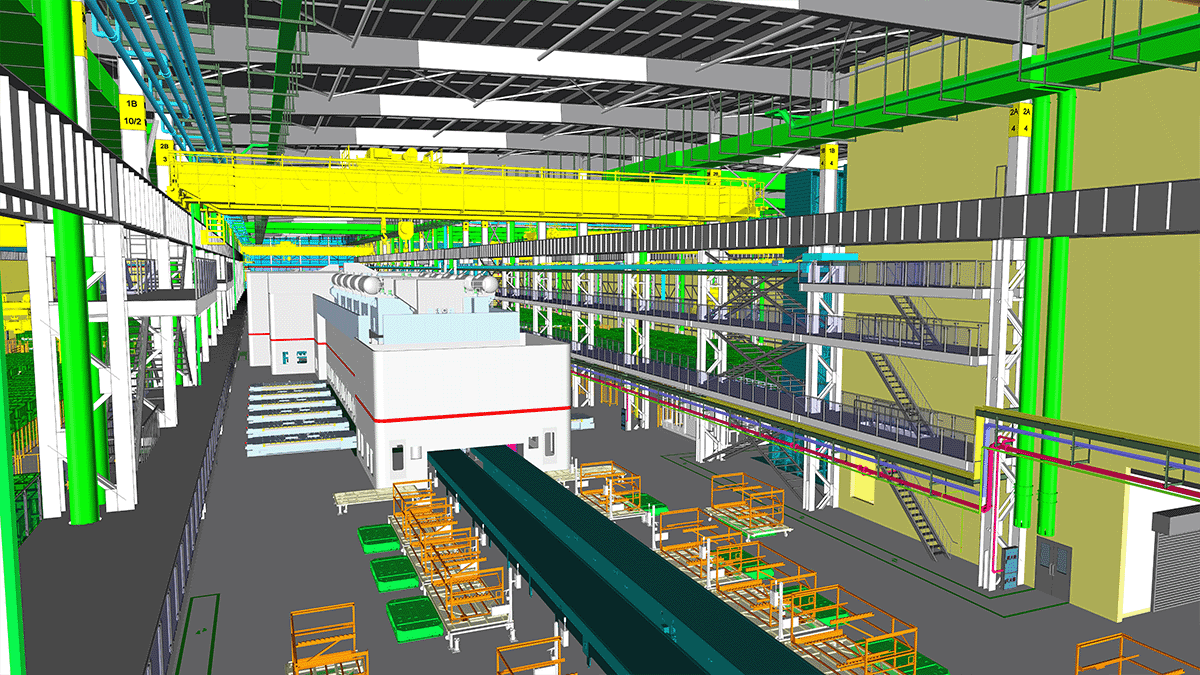

Bentley Software: iTwin Capture, MicroStation, OpenPlant Modeler, ProjectWise, ProStructures, STAAD, SYNCHRO, OpenBuildings, LumenRT

Additional Context: As part of a large-scale green transformation, Baosteel used Bentley’s digital twin technology to coordinate 11 engineering disciplines and accelerate delivery by 50%. The data-driven approach achieved millimeter-level precision, cut rework to below 1%, reduced welding costs by 35%, saved RMB 49 million, and lowered annual CO₂ emissions by 12,000 tons while improving energy efficiency by 8%.

Project

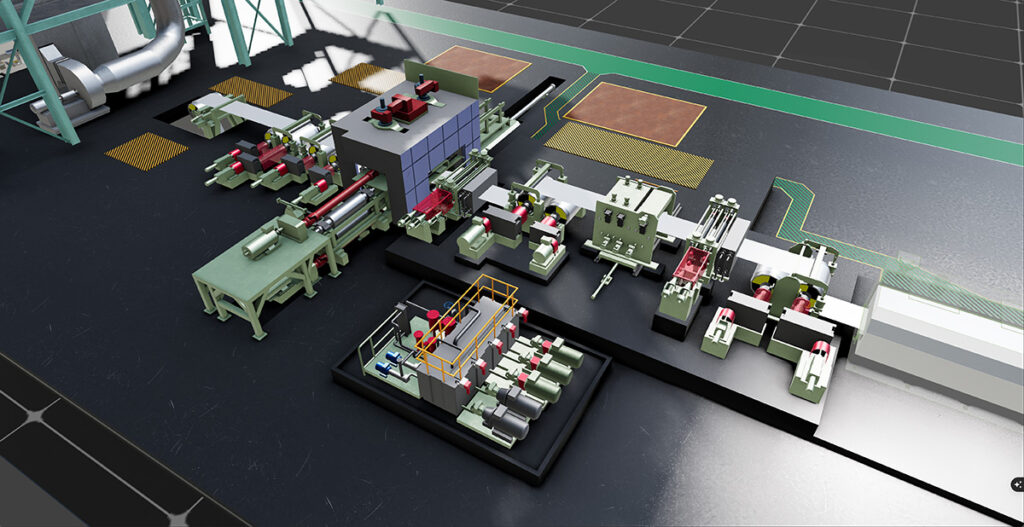

The Baoshan Iron and Steel Plant Structural Optimization Project in Shanghai was an upgrade initiative designed to increase product corrosion resistance and service life. Instead of relying on traditional color coatings, a new system treats steel with a different mix of metals via hot-dip galvanizing. This upgraded plant is designed to treat up to 310,000 tons of steel each year.

Led by Baosteel Engineering & Technology Group, the project encompasses new process design, equipment upgrades, intelligent manufacturing, and digital delivery, and is a benchmark for green transformation in the metallurgical sector.

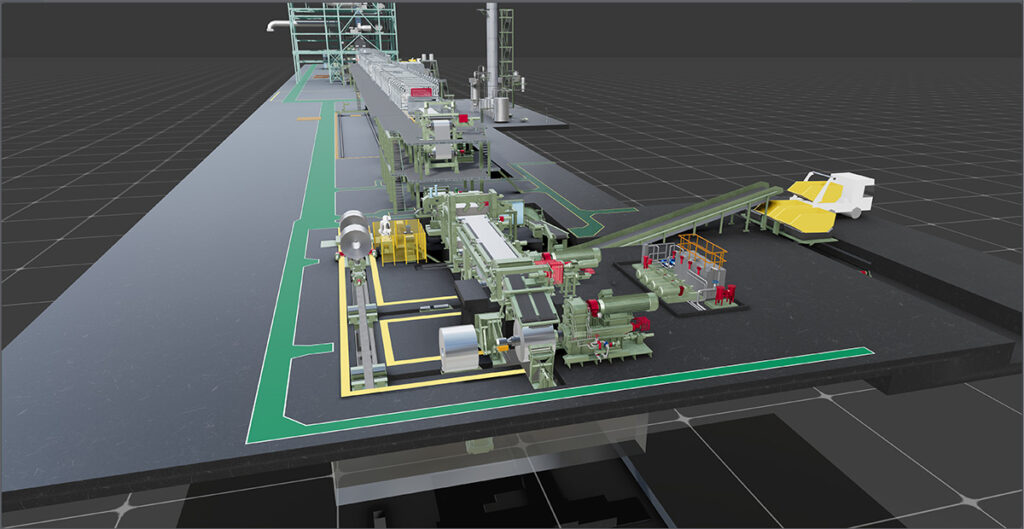

The project faced significant challenges. Firstly, 40% of the plant was to be retained, but deviations between legacy drawings and site conditions of over 200mm meant engineering the retrofit was going to be tricky. Secondly, the need to coordinate across 11 disciplines, 780 equipment sets, 12 significantly large components, such as an 18-meter furnace shell, and over 2,000 pipelines added a layer of logistical complexity, with a high risk of issues such as collisions during construction. And, finally, the project timeline was compressed from the conventional 12 months to just 6 months, leading to the need for new thinking, such as an increased number of prefabricated pipelines.

Facts

- Baosteel digitally delivered a transformational steel plant upgrade project through advanced modelling software, improved collaboration capability, and intelligent construction technologies, achieving millimetre-level accuracy and streamlined delivery.

- Significant engineering challenges were overcome, including coordinating across 11 disciplines, logistical complexity, inaccurate legacy drawings, and a compressed delivery timeline from 12 months to 6 months.

- Bentley software streamlined collaboration, and allowed real-time decision-making through digital twin workflows, resulting in reduced costs, improved efficiency, and substantial environmental benefits for the plant.

"Thanks to Bentley's technical empowerment, we can utilize data to drive the green transformation of the steel industry"

- David Liu, Big Data Center, China Baowu Design Institute

Solution

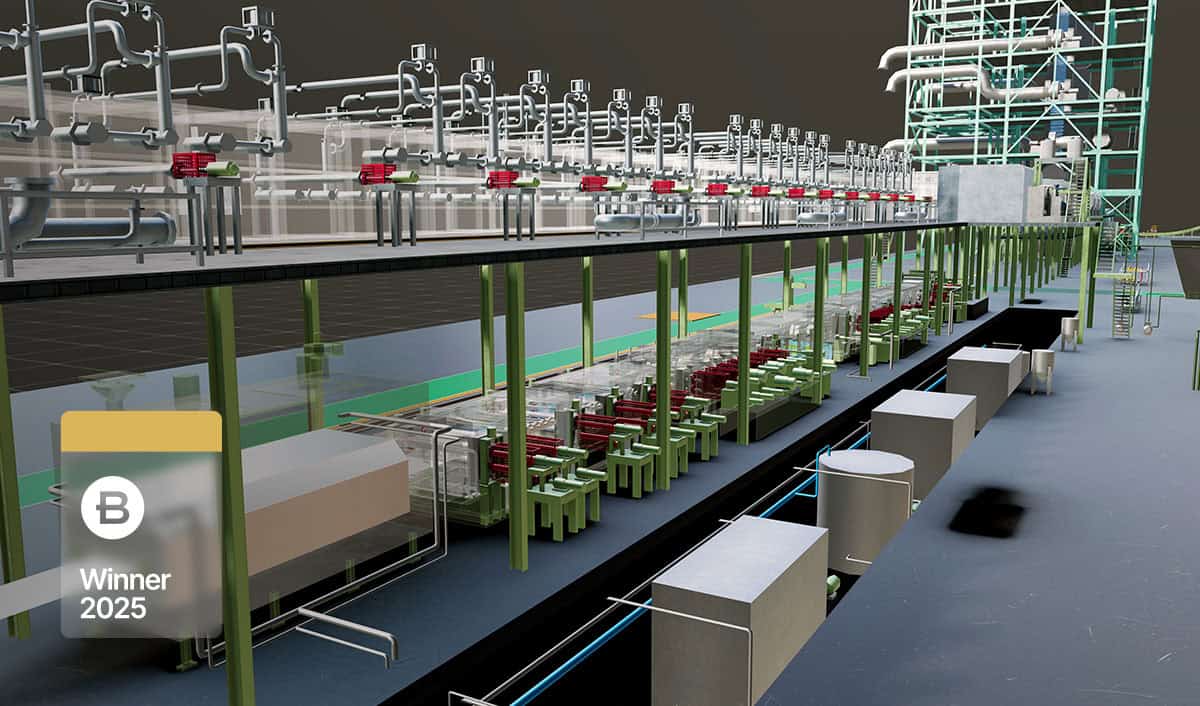

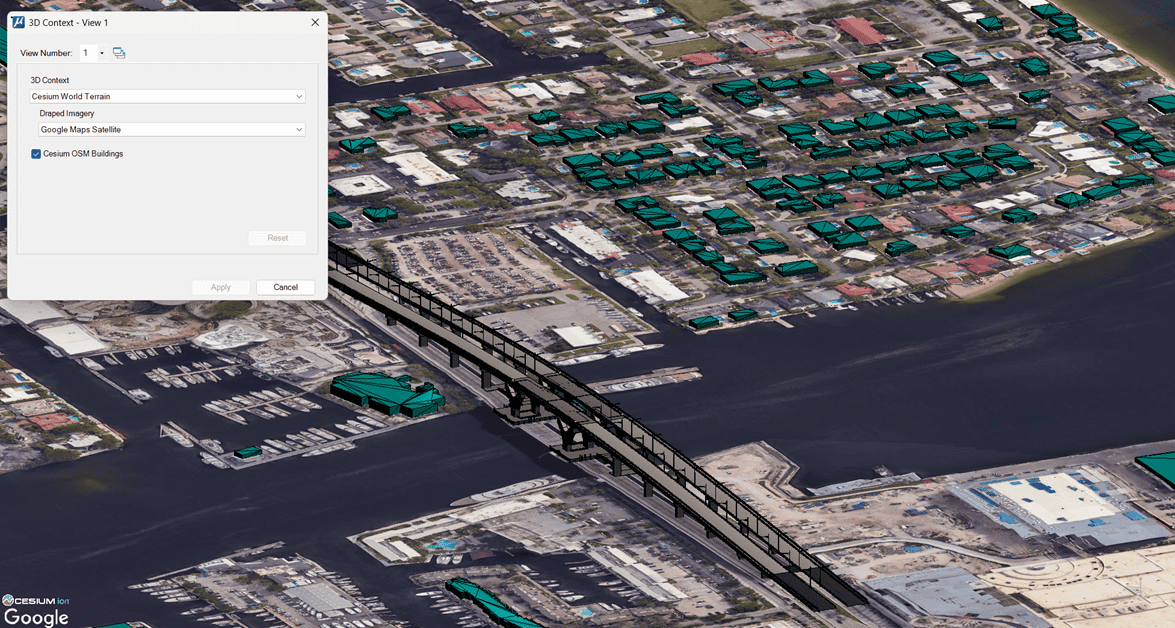

The project was delivered through a data-driven, collaborative approach that established a benchmark for digital and intelligent construction in the steel industry. The team began by digitally reconstructing 40% of the plant area, using reality modelling tools in iTwin Capture Modeler. Combined with MicroStation, this helped them achieve millimetre-level accuracy to align the new infrastructure with the existing and allowing precise identification and demolition of outdated structures.

To manage collaboration across 11 engineering disciplines, ProjectWise provided a shared digital workspace for model review and closed loop change management, allowing real-time synchronization of design changes and reducing interface collision rates from 12% to below 3%. This platform processed thousands of digital work orders, streamlining communication and minimizing errors.

With only six months to complete a project that would normally take a year, OpenPlant Modeler supported modular pipeline design, allowing for extensive prefabrication. SYNCHRO was used in the construction phase to simulate transport routes and lifting operations, ensuring safe and conflict-free installation of large components like the 18-meter annealing furnace shell. The integration of digital twins and physical systems was realized by embedding engineering data into an iModel, supporting real-time decision-making and predictive maintenance.

These and other Bentley products were instrumental throughout, but the focus remained on holistic digital transformation, collaboration, and efficiency. The project’s delivery resulted in significant reductions in design cycle time, costs, and environmental impact, setting new standards for the industry.

Outcome

The project achieved many notable results. Design changes dropped from 3 days to 4 hours, and the design cycle was halved. Construction advanced by 92 days, with furnace installation shortened by 14 days. Pipe connection accuracy improved through site reality capture, cutting rework from 15% to 0.8%. Prefabrication reduced welding costs by 35%, saving RMB 21m and volatile emissions from 3.5kg to 1.2kg per ton of steel. Using the digital twin for predictive maintenance cut spare parts inventory by 40%, saving RMB 28m annually. The plant also reduced CO₂ emissions by 12,000 tons per year and expects 8% energy savings.

Software

Bentley LumenRT was used to create immersive visualizations of the steel plant’s digital models, enabling stakeholders to better understand design concepts and construction scenarios throughout the project.

Bentley iTwin Capture enabled the generation of a highly detailed point cloud model of the plant, enabling millimeter-level accuracy in digital reconstruction and alignment of new and existing structures.

Bentley MicroStation was used to achieve millimeter-level accuracy by aligning point cloud data with BIM models, enabling precise identification and correction of structural discrepancies.

Bentley OpenPlant facilitated modular pipeline design and prefabrication, enabling a higher prefabrication rate and precise installation that significantly accelerated project delivery.

Bentley ProjectWise enabled a collaborative platform for 11 different disciplines, unifying design data management and automating the change process, which streamlined coordination and reduced interface conflicts.

Bentley ProStructures was used to develop a parametric steel structure template library, which increased modeling efficiency and reduced material statistical errors, supporting precise and efficient construction.

Bentley STAAD was used to perform structural analysis and embed engineering parameters into the project’s digital twin, supporting precise modeling and real-time decision-making.

Bentley SYNCHRO provided simulation and optimization of transportation routes for heavy equipment, helping avoid hoisting conflicts and shortening the installation period of key components.

Bentley OpenBuildings helped build foundational models for all equipment disciplines, enabling collaborative iterations between civil and process engineering and achieving high-precision pile foundation positioning.

Explore how Bentley’s energy production solutions enable faster, smarter, and greener industrial upgrades like Baosteel’s.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.