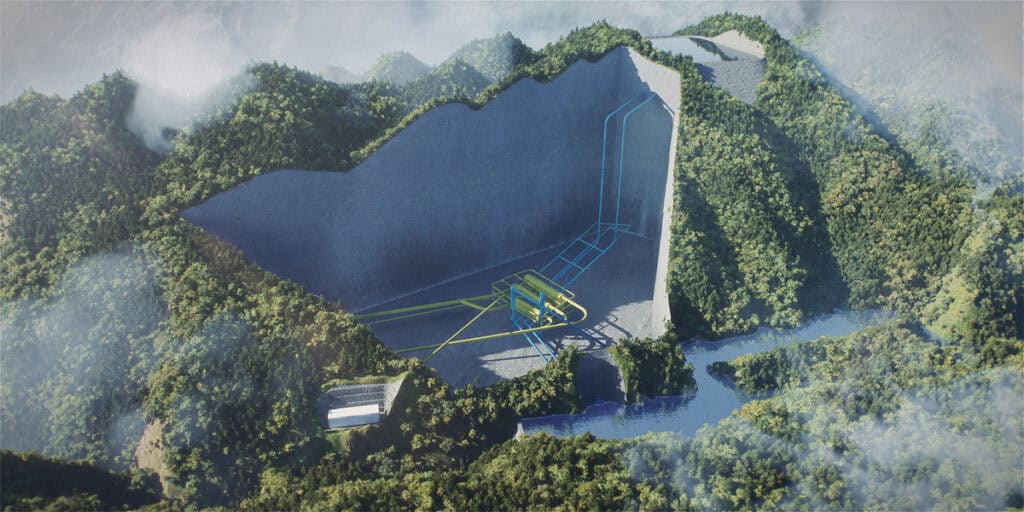

Caiziba Pumped-Storage Power Station

Organization: Shanghai Investigation, Design & Research Institute Co., Ltd. (SIDRI)

Project Name: Caiziba Pumped-Storage Power Station

Location: Fengjie County, Chongqing, China

Project Phase: Construction and Commissioning

Expected Completion Date: Not specified

Estimated Project Cost: Not specified

Bentley Software: iTwin Platform, iTwin Capture, Bentley Descartes, Bentley LumenRT, MicroStation, OpenBuildings Designer, OpenPlant, PLAXIS, ProjectWise, STAAD, SYNCHRO

Additional Context: The Caiziba Pumped-Storage Power Station is a pioneering clean energy project and the first of its kind built in a region with complex karst geology. As part of China’s “14th Five-Year Plan,” SIDRI used Bentley’s digital twin technology to integrate multisource data, enhance collaboration, and mitigate risks associated with caves, fissures, and underground rivers. This digital-first approach improved accuracy, reduced construction time, and minimized environmental impact.

Project

The Caiziba Pumped-Storage Power Station, engineered by Shanghai Investigation, Design & Research Institute Co., Ltd. (SIDRI), is a groundbreaking energy infrastructure project located in Fengjie County, Chongqing. As part of China’s “14th Five-Year Plan” and the 2021–2035 roadmap for pumped-storage development, Caiziba is the first large-scale facility of its kind built in a complex region consisting of karst geology. This type of environment presents significant construction challenges. It is typically riddled with caves, fissures, and underground rivers. Water seepage is always an issue, requiring advanced engineering to manage water infiltration. There are critical risks to consider when constructing tunnels through the fragile rock that is prevalent in this region, such as collapses, water inrushes, and mud outbursts. During operations, reservoir seepage may contaminate groundwater, threatening the local water ecosystem.

Facts

- The project faced significant engineering challenges due to difficult karst geology, which typically includes caves, fissures, underground rivers, and water seepage risks.

- SIDRI used Bentley’s digital solutions to improve cross-discipline collaboration efficiency by 40%, reduce design errors by 65%, and enable 75% reuse of design resources.

- Hydromechanical modeling time was cut by 75%, and 1,850 design conflicts were detected and resolved, saving CNY 4.5 million in rework. Concrete use was reduced by 3,200 cubic meters, and the construction period was shortened by 42 days. Substantial costs and carbon emission reductions were achieved through digital project delivery.

"Bentley's iTwin digital twin technology has achieved dynamic coupling of geological modeling and construction, optimized excavation volumes by 120,000 cubic meters, shortened the construction period by 42 days, and reduced carbon emissions from construction by 8,960 tons, providing efficient infrastructure support for the regional clean energy transformation."

Hu Runxin, Project BIM Manager, SIDRI

Solution

SIDRI chose Bentley products for their robust engineering-level data integration, multidiscipline compatibility, parametric extensibility, full lifecycle data management, and superior large-scale terrain processing capabilities.

Their strategy to first develop a 3D geological model by integrating exploration data, including drilling, geophysics, and remote sensing, marking caves, fissures, and underground rivers. Then, they used GIS analysis to predict high-risk seepage areas. Finally, they adopted BIM and finite element analysis to optimize underground cavern support schemes.

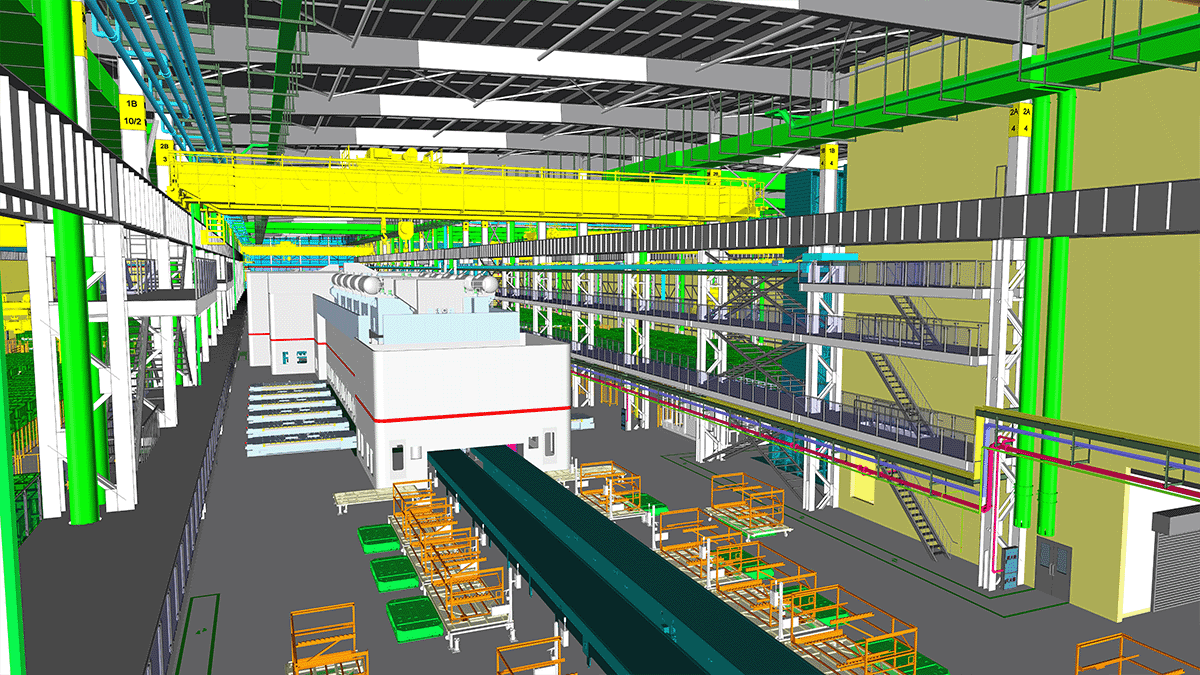

Bentley’s OpenBuildings Designer enabled a parametric equipment library, intelligently linking equipment selection and 3D modeling, allowing self-adaptive creation of intricate hydraulic machinery. iTwin Capture was used to generate high-precision geological models which dynamically linked with tunnel design models, supporting real-time adjustment of support parameters.

A collaborative design environment was established around a 3D hydromechanical equipment layout, which improved cross-discipline collaboration efficiency by 40% and reduced design errors by 65%. Modular products and parametric components were developed for reuse across multiple projects, raising design resource reuse to over 75%. The team also carried out 3D design reviews to enable model/drawing checks, collision detection, and code verification. 3D visualization was used for rapid scheme comparison, tripling decision efficiency. They also integrated 3D modeling with hydraulic calculations for water conveyance development, reducing the design cycle by 60%.

SIDRI developed a digital design platform, built on Bentley’s iTwin platform. This unified multidiscipline design automated drawing generation and enabled intelligent, automatic calculations, such as changes in quantities when water conveyance routes are changed. It helped achieve 98% first-time design data accuracy, providing a robust digital foundation for the project.

Outcome

The team’s hydromechanical modeling time was cut by 75%, and standard components were able to be reused 300 times. They detected and resolved 1,850 design conflicts in 3D design reviews, saving around CNY 4.5 million in rework. Parametric tunnel lining design reduced concrete use by 3,200 cubic meters, equivalent to 8,960 tons of carbon emissions. Combining terrain and design data shortened the critical construction path by 42 days.

Additionally, iTwin Capture reduced field survey costs by CNY 1.2 million and eliminated excavation of 120,000 cubic meters of rock. Digital design cut steel usage by 860 tons, lowering carbon emissions by 2,150 tons. ProjectWise boosted collaboration efficiency by 80%. By overcoming the engineering challenges, SIDRI has transformed Caiziba into a model project, setting a precedent for future developments in similarly complex terrains. It exemplifies innovation in clean energy and environmental stewardship, blending technical mastery with ecological sensitivity.

Software

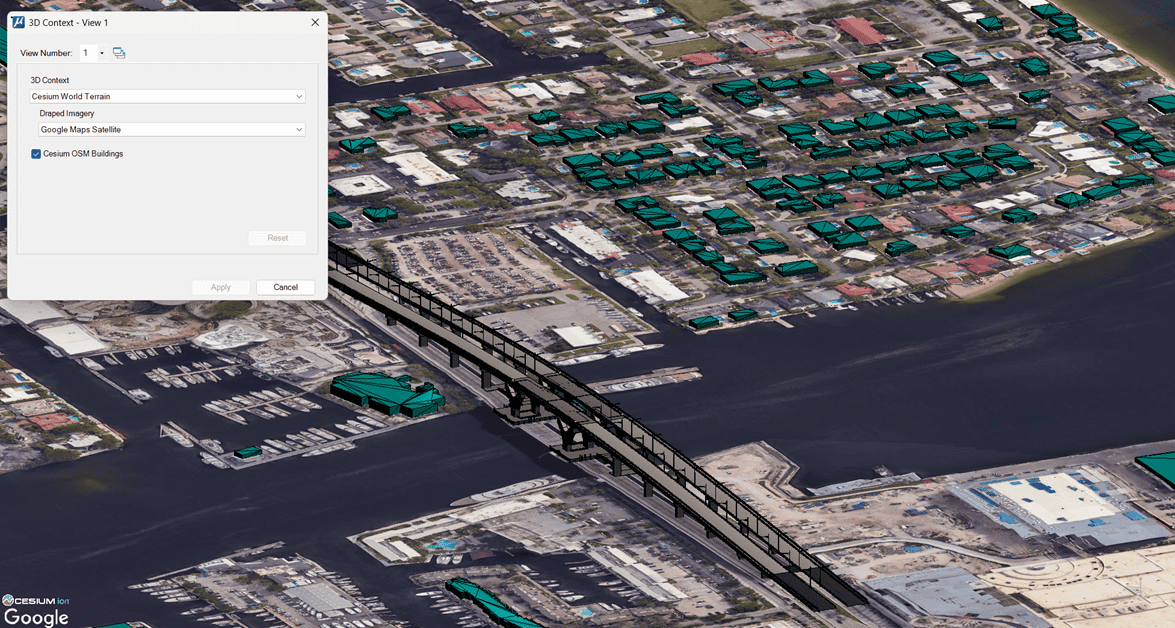

- The Bentley iTwin platform was used to integrate multisource data into a unified digital twin, enabling real-time collaboration and streamlining decision-making throughout the project.

- iTwin Capture was used to produce high-resolution reality models of the site, enabling accurate visualization and analysis of complex terrain and construction conditions.

- Bentley Descartes was used to efficiently process large-scale reality modeling data, enabling precise terrain feature extraction and seamless integration with design models.

- Bentley LumenRT was used to create immersive visualizations and animated simulations of the power station, enhancing stakeholder communication and project presentations.

- MicroStation was used to create and manage detailed design models for the power station, supporting precise engineering and seamless integration with other digital tools.

- OpenBuildings Designer was used to develop detailed architectural and structural models, supporting integrated design and coordination across disciplines.

- OpenPlant was used to model and manage the plant design aspects of the project, ensuring accurate piping and equipment layouts integrated within the overall digital workflow.

- PLAXIS was used to perform advanced geotechnical analysis, supporting the design and safety evaluation of underground structures and slope stability.

- ProjectWise was used to manage and share engineering data across teams, ensuring secure collaboration and streamlined workflows throughout the project.

- STAAD was used to perform structural analysis and design for key components of the power station, ensuring safety, stability, and compliance with engineering standards.

- SYNCHRO was used to create 4D construction simulations, enabling dynamic scheduling, progress tracking, and enhanced project management.

Explore how Bentley’s energy production solutions help deliver complex infrastructure like pumped storage power stations.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.