Salvador-Itaparica Bridge Project

Organization: Sener Mobility

Project Name: Salvador-Itaparica Bridge Project

Location: Salvador da Bahia and Itaparica Island, Brazil

Project Phase: Design

Expected Completion Date: Not specified

Estimated Project Cost: BRL 10.42 billion

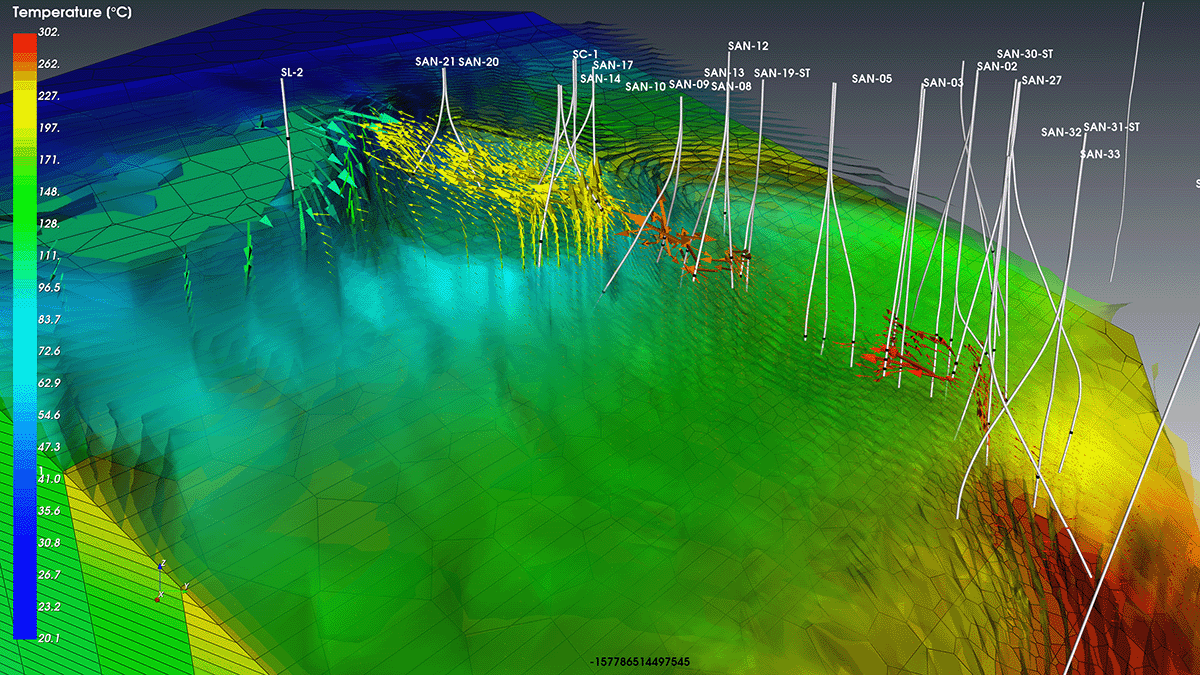

Bentley Software: Leapfrog Works, PLAXIS

Additional Context: Sener Mobility applied digital geotechnical engineering to optimize foundation design for a 12.5-kilometer bridge connecting Salvador da Bahia and Itaparica Island. By adopting a 3D modeling workflow with Leapfrog Works and PLAXIS, the team enhanced geological analysis, improved stability assessment, and achieved measurable reductions in design time and rework.

Project

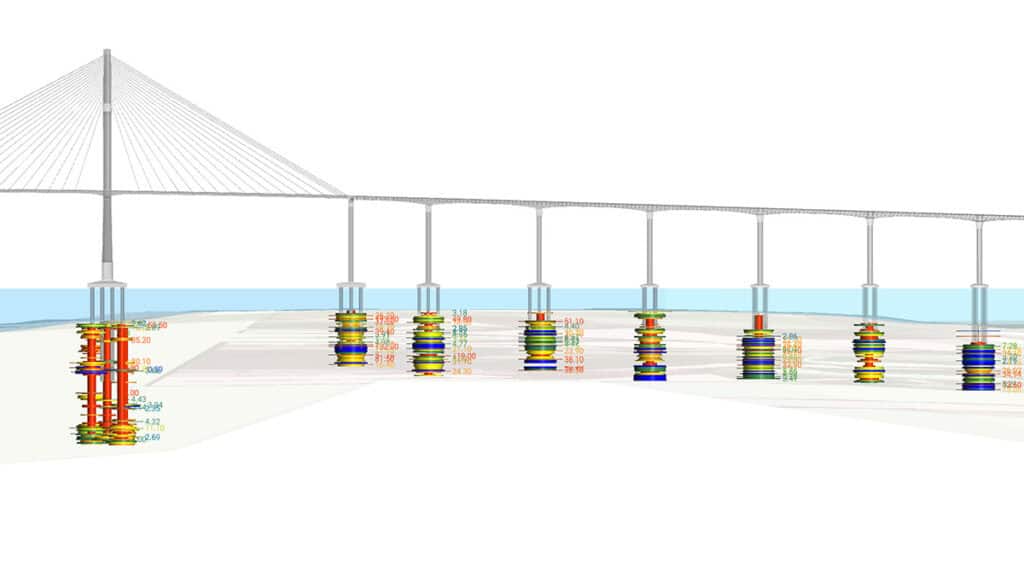

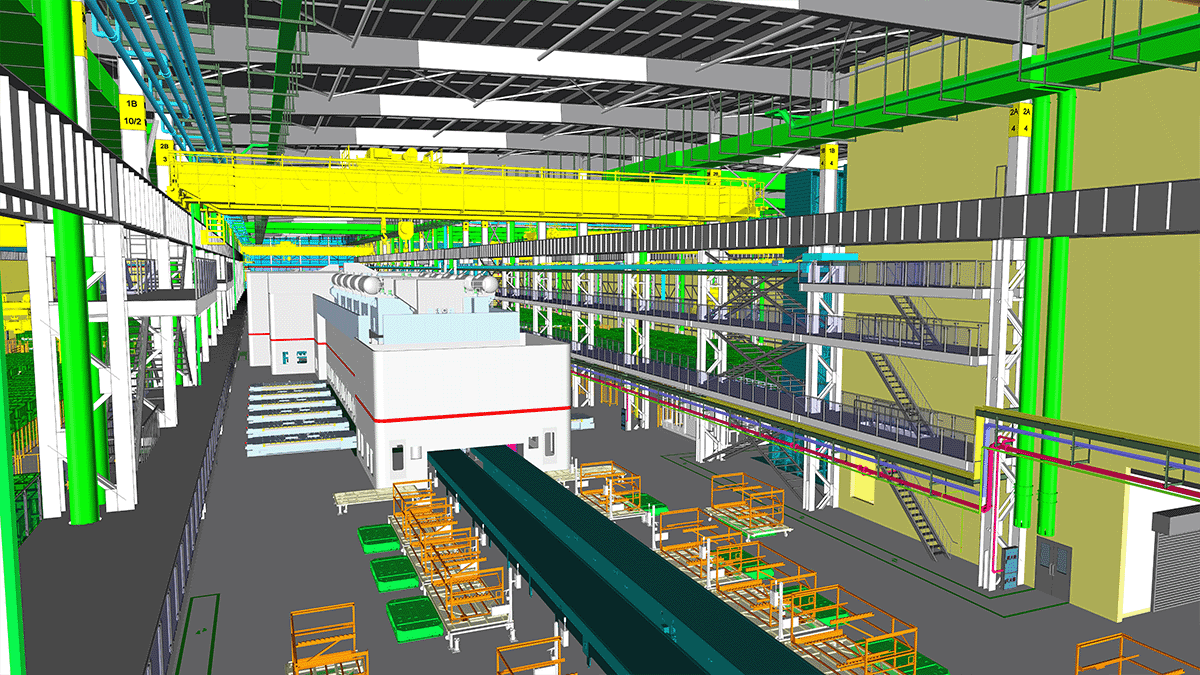

The Salvador-Itaparica Bridge project in Brazil aims to construct a new, 12.5-kilometer road system connecting Salvador da Bahia and Itaparica island. This massive undertaking includes a 922-meter cable-stayed main bridge and two large access bridges. Sener Mobility was tasked with the complex geotechnical design and calculations for the bridge’s foundations. The primary challenge was to analyze complicated soil and rock conditions, processing multiple data sources to ensure the structure’s stability and safety. The project’s goal is to significantly improve connectivity and foster regional development.

Facts

- Project length: 12,500 meters

- Project cost: BRL10.42 billion

- Work hours saved: 1,000

- Geology interpretation time reduction: 20%-30%

- Pile design optimization:10%

- Reduction in design changes during construction: 15%

"The deployment of Seequent’s Leapfrog Works and PLAXIS software has significantly improved Sener's geotechnical analysis and modeling capacity for the Ponte Salvador-Ilha de Itaparica project. This digital transformation has allowed us to build increasingly representative geological models, optimize foundation design, and mitigate geotechnical risk, thus improving project delivery efficiency and reliability."

Eloy Joaquín Carrillo García, Senior Project Engineer | Geological & Geotechnical Modeling Team Lead, Sener Mobility

Solution

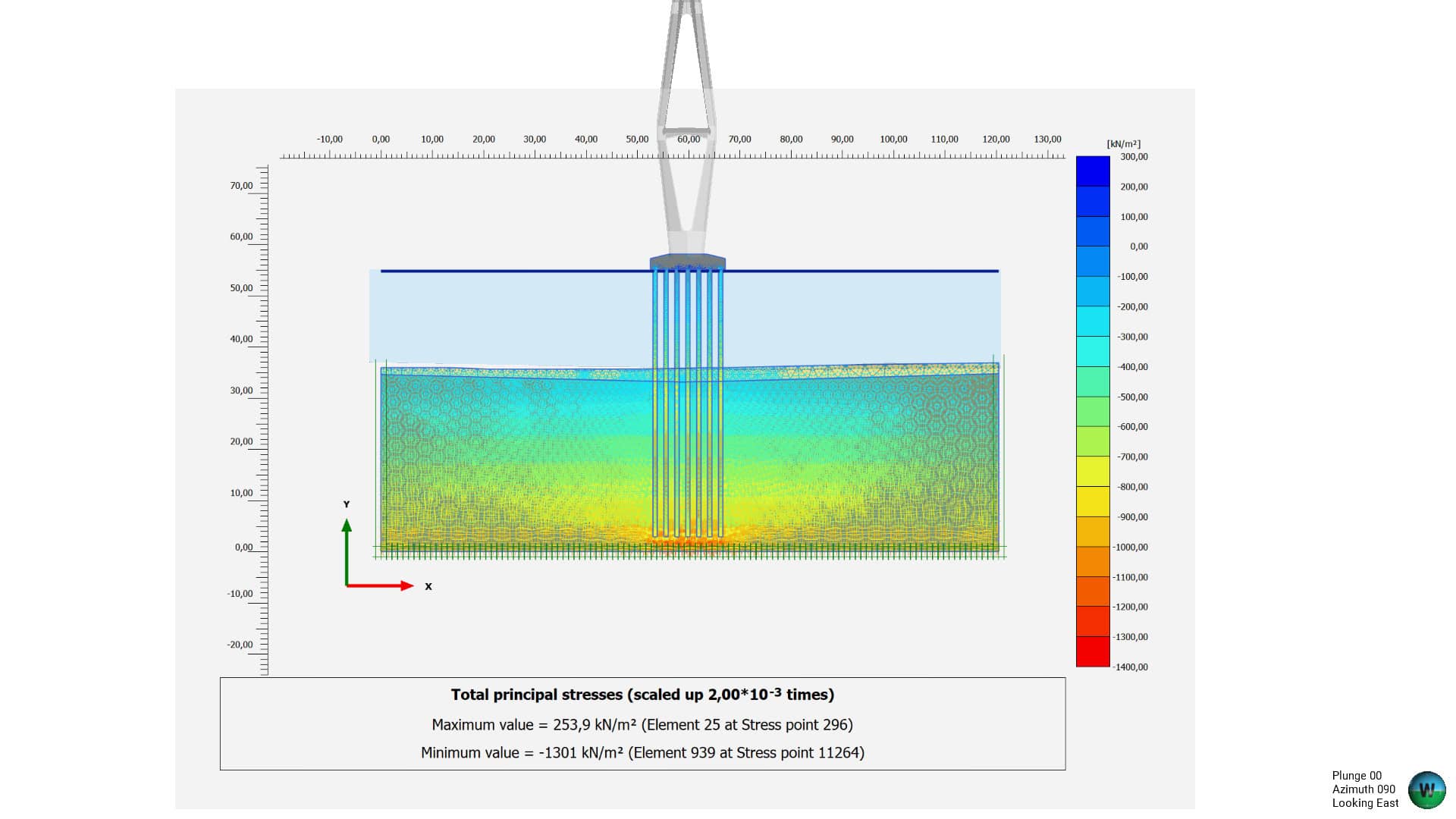

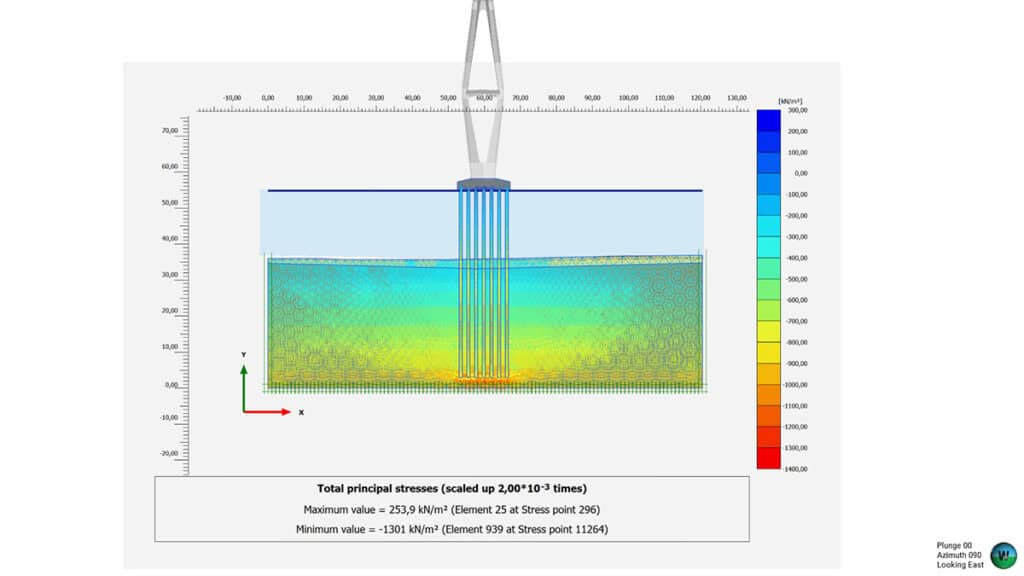

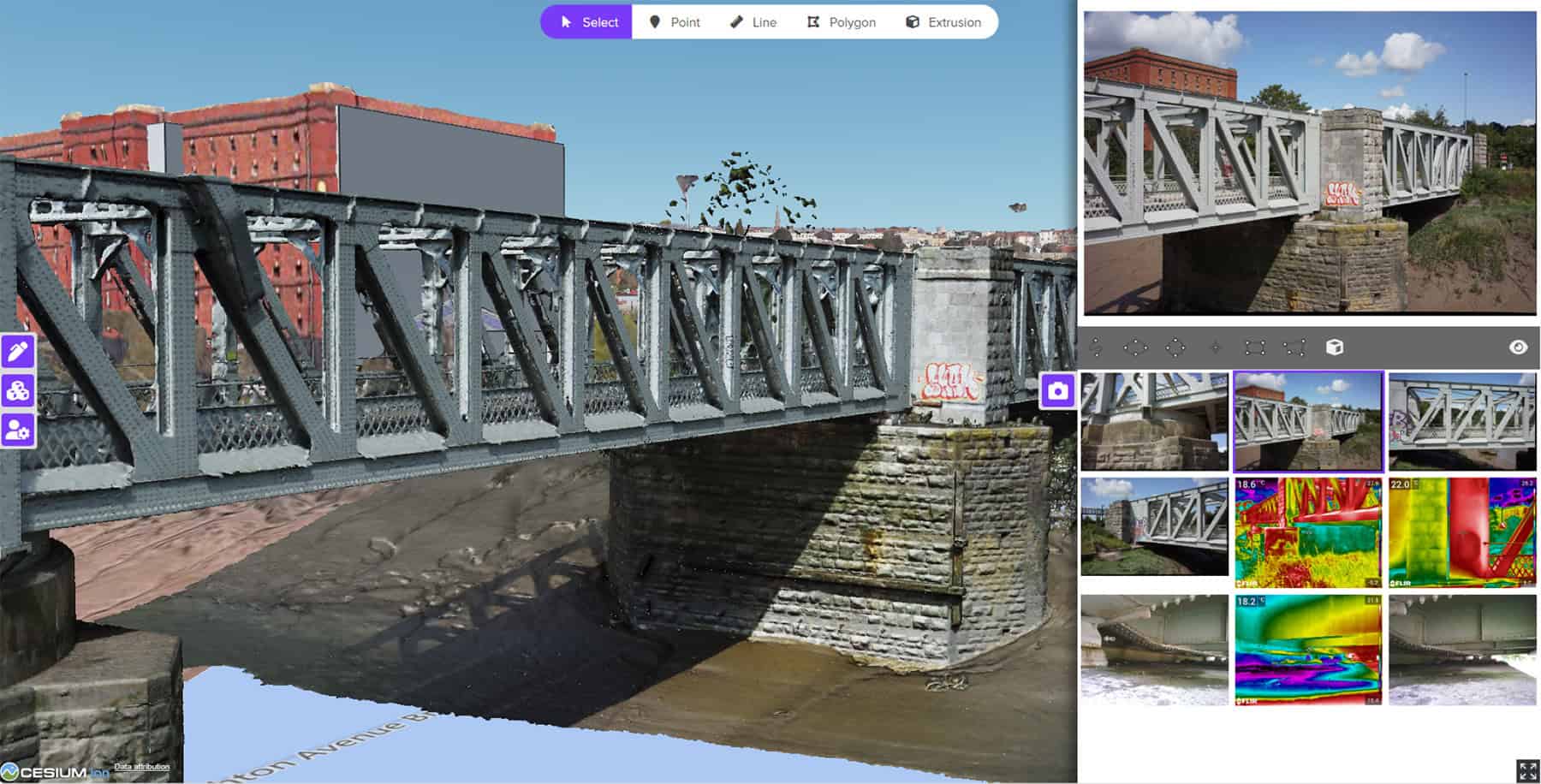

Sener moved from a traditional 2D workflow to a fully integrated 3D digital approach using Leapfrog Works and PLAXIS from Seequent, The Bentley Subsurface Company. This shift was critical to overcoming the limitations of their previous software, which struggled with the complexities of 3D geological data. Leapfrog Works was instrumental in creating high-fidelity 3D geological models from diverse data sources, providing a clearer and more accurate understanding of the heterogeneous ground conditions. PLAXIS was then used to perform advanced finite element analysis, simulating complex soil-structure interactions to analyze the mechanical performance and long-term stability of the bridge’s deep foundations.

Outcome

By implementing a digital-first approach, Sener significantly improved its geotechnical workflow, leading to more efficient and reliable designs with measurable return on investment:

- Enhanced geotechnical insight: The use of 3D models reduced the time spent interpreting geological conditions by 20%-30% compared to traditional 2D methods, allowing the team to rapidly identify potential hazards.

- Optimized and efficient design: The advanced analysis capabilities led to a 10% optimization in pile design and reduced the design duration by 10%-20%, saving an estimated 1,000 work hours.

- Reduced risk and rework: The creation of a more accurate geotechnical model is estimated to reduce the chances of costly design changes during the construction stage by about 15%, preventing delays and overruns.

- Significant material savings: The ability to optimize the foundation designs is projected to reduce material costs, such as concrete and steel, by 5%-10%.

Software

Leapfrog was used to generate complex and accurate 3D geological models, providing clarity on soil and rock conditions.

PLAXIS was employed for complex finite element analysis and simulations of soil-structure interaction to design and optimize deep foundations.

Discover how PLAXIS can improve your next geotechnical design project with powerful 3D modeling and risk mitigation tools.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.