The Prosperity Intelligent Manufacturing Industrial Park

Organization: MMI Planning & Engineering Institute

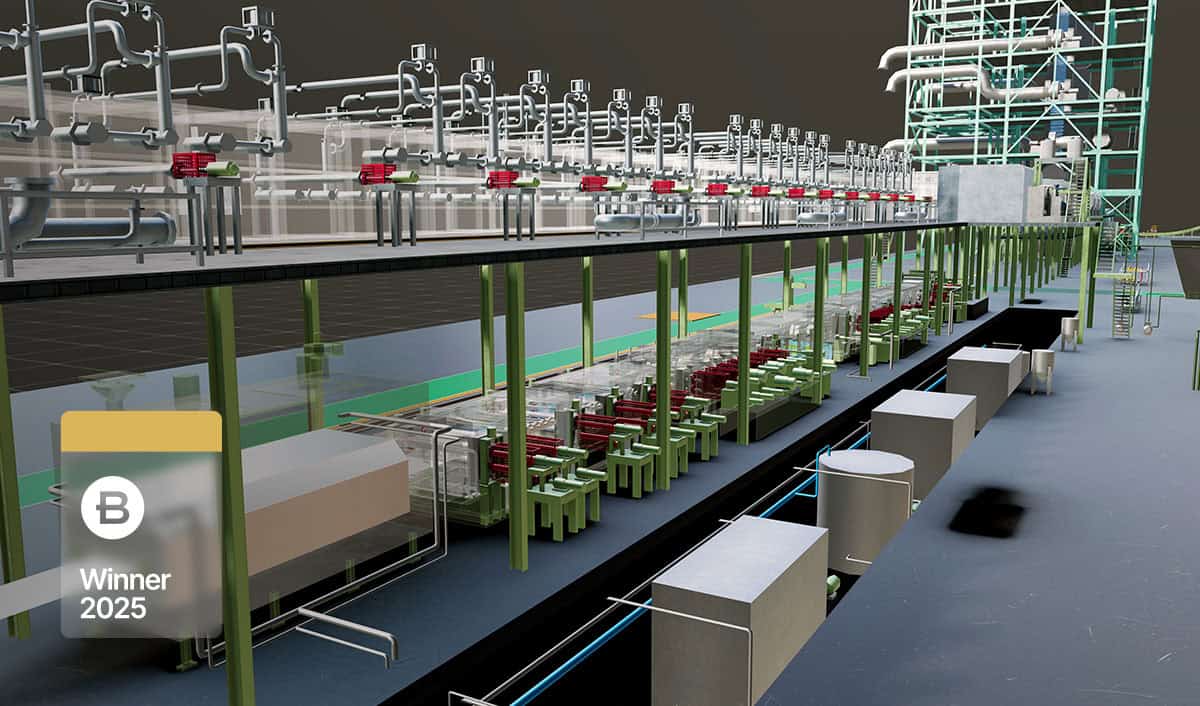

Project Name: Stamping Workshop of the Prosperity Intelligent Manufacturing Industrial Park

Location: Changchun City, China

Project Phase: Completed

Expected Completion Date: November 2023

Estimated Project Cost: 1.3B Yuan ($182.5 million)

Bentley Software: Bentley LumenRT, MicroStation, ProjectWise, OpenBuildings Designer

Project

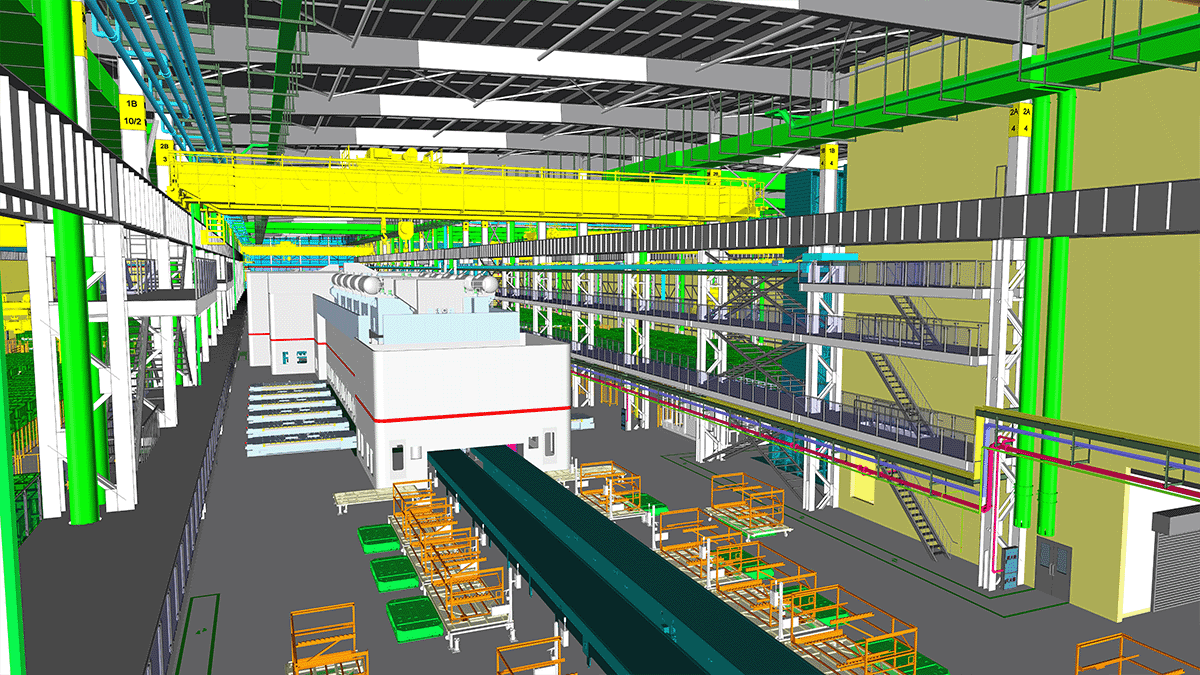

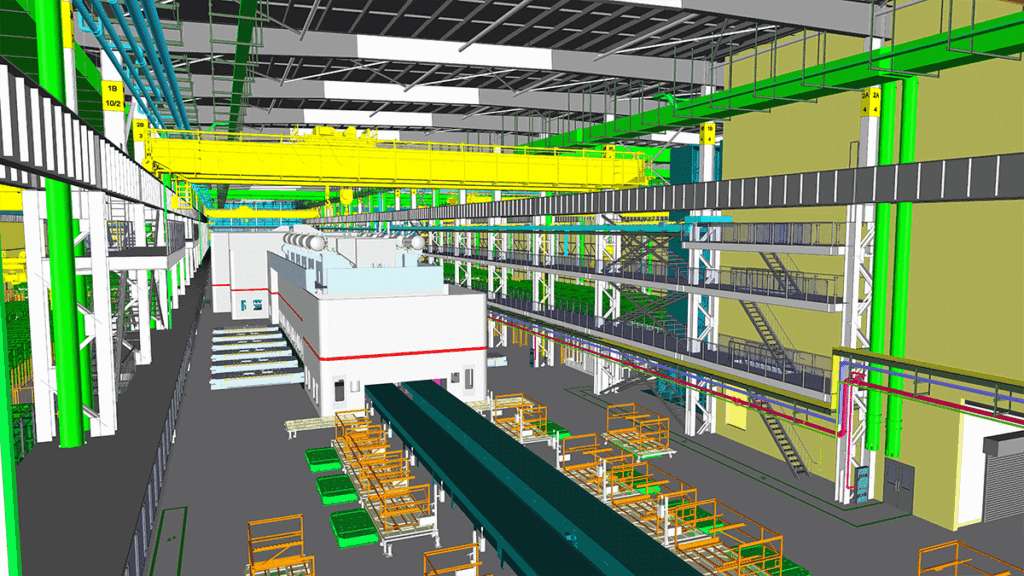

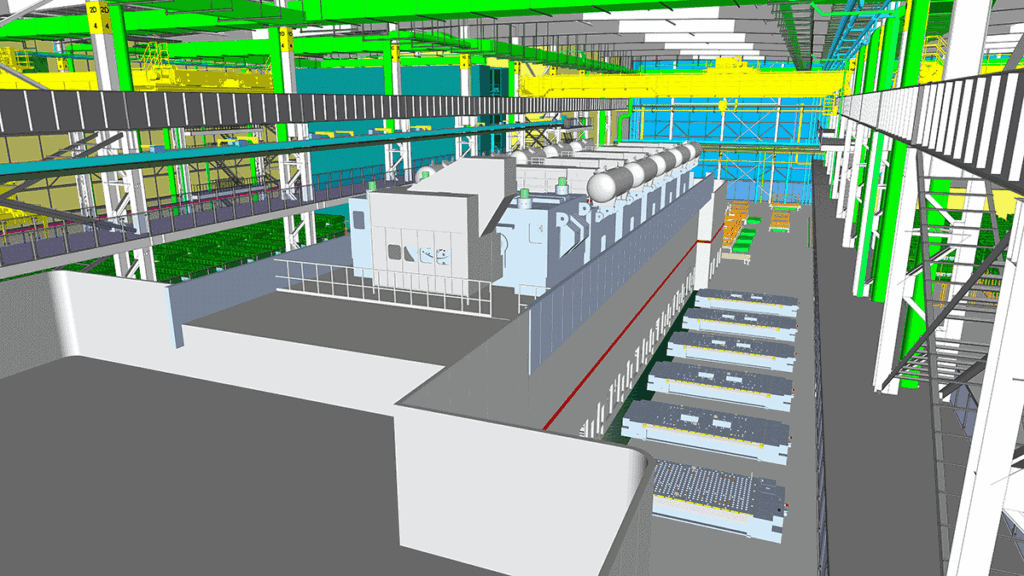

The Prosperity Intelligent Manufacturing Industrial Park Project in the Changchun Automobile Economic and Technological Development Zone, also known as Prosperity Factory, is located in Changchun, Jilin Province, China. The project covers a construction area of 435,000㎡ and has a total investment of RMB 7.8 billion. As one of the major projects of Jilin Province’s “Three Early” (Start Early, Implement Early, Achieve Results Early) initiatives, it supports the mission of implementing the “831” and “3341” action plans of China FAW, promoting the continuous business growth of the Hongqi brand, and driving the regional sustainable economic and social development of Changchun. MMI Planning & Engineering Institute needed to meet the spatial occupancy, operating trajectory, and safety space requirements while also considering the design and construction of the civil engineering structures, such as beams, columns, platforms, and every pipeline and hanger of the utility systems within the workshop.

Facts

- Design efficiency was increased by 25% and saved equipment modelling time by 90%

- Reduced offline communication during the design process by 80% and shortened the design cycle by 20 days and saved RMB 5 million

“OpenBuildings Designer is the most widely used and most helpful digital software in our company's digital process planning work. It has provided the most solid and reliable technical support for the MII Institute IX's transition towards digital and intelligent process design.”

Pengwei Lu, Designer, MMI

Solution

Bentley applications were selected because they met all the digital process planning requirements of this project. During the process design, OpenBuildings Designer was used for 3D process design to visualize the spatial occupancy, operating trajectory, and safety space for operation and running of process equipment, which greatly enhanced the efficiency and quality of the designers’ work. The MMI Institute specifically developed the parameters for their equipment based on the OpenBuildings Designer software and several related plugins, which has significantly enhanced MMI Institute IX’s process 3D design capabilities and quality. During the civil engineering design process, ProjectWise was employed as the 3D design platform for collaborative management, which enabled multi-disciplinary synchronized online BIM forward design, greatly reduced design errors, omissions, and clashes, and provided high-quality 3D design drawings, thereby minimizing the need for modifications in later stages. In this project, 3D process equipment modeling and integration were applied in an automotive factory’s stamping workshop for the first time.

Outcome

In the digital process planning, the use of OpenBuildings Designer software saved 650 man-hours, reduced the designers’ working time by 25%, and enhanced the quality of the final deliverables. ProjectWise was used for collaborative design management and enabled full-process supervision of project implementation documents, reduced offline communication during the design process by 80%, shortened the design schedule by 20 days, and identified and eliminated a total of 2,460 clashes in the design phase, equivalent to a saving of approximately RMB 5 million.

Software

Bentley LumenRT

MicroStation

OpenBuildings Designer

ProjectWise

Learn more about how MicroStation, OpenBuildings, and ProjectWise can help your project.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.