APD Global’s Digital Substation Design for Perth’s Power Upgrade

Organization: APD Global

Project Name: PTA Sutherland St. Load Upgrade – Digital Substation Design and Infrastructure Modernization

Location: Perth, Western Australia

Project Phase: Ongoing construction with digital engineering implementation

Expected Completion Date: 2027

Estimated Project Cost: AUD 25 million

Bentley Software: MicroStation, OpenUtilities Substation, iTwin Capture, Bentley Descartes, Bentley LumenRT, ProjectWise, Promis.e

Additional Context: APD Global has been entrusted by Western Power with the engineering and detailed design of the 132/22kV Bunning Lake Substation, which will supply power to support the modernization of Perth’s rail infrastructure. Bentley’s integrated design and digital twin solutions improved delivery speed by 15%, reduced material waste by up to 2%, and enabled real-time cross-discipline collaboration.

Project

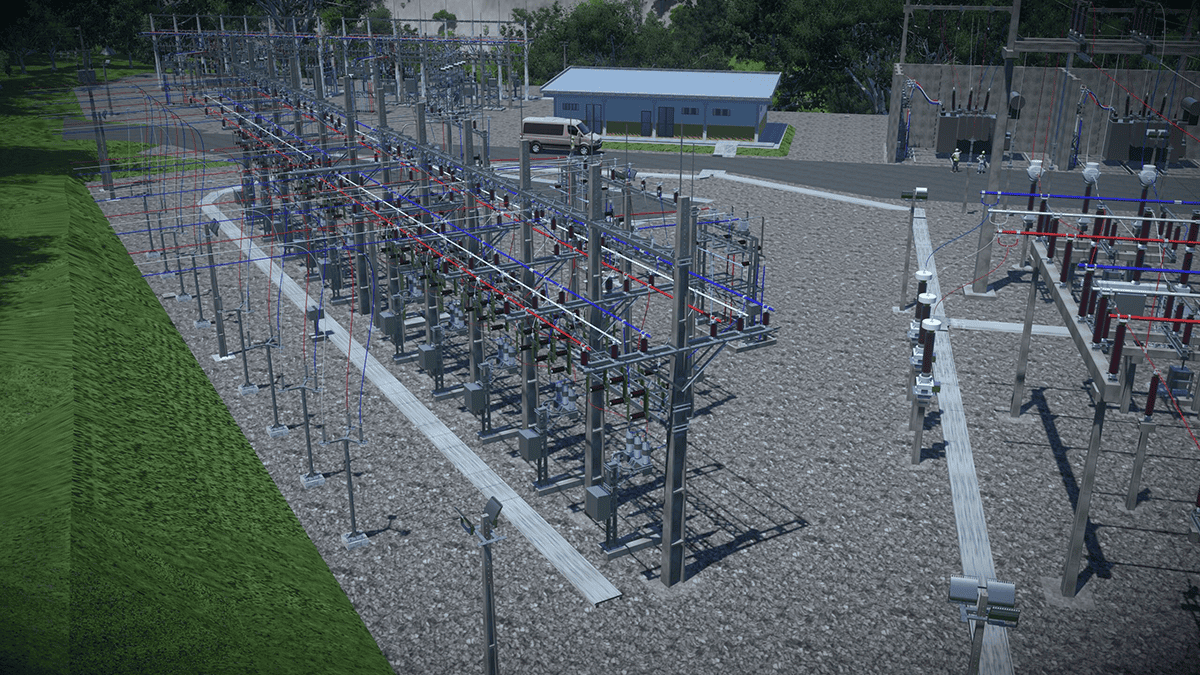

In Perth, Western Australia, the PTA Sutherland St. Load Upgrade project is helping modernize the city’s electrical infrastructure to support its growing public transport system. APD Global is responsible for the engineering and detailed design of a new 132/22kV Bunning Lake switching substation, which is critical to enhance the electrical supply capacity and reliability for the Public Transport Authority. The project aims to support the growing demand for electricity in the area and ensure a stable power supply for public transport operations. APD Global is delivering the full spectrum of multidisciplinary engineering and detailed design for the 132/22kV Bunning Lake Substation. The project is currently in the construction phase and the expected to complete in 2027. APD Global uses Bentley software to coordinate across disciplines, reduce design errors, and ensure compliance with safety and performance standards. This initiative is a key part of Perth’s strategy to build a more resilient and efficient energy network.

Facts

- 15% faster delivery through automated design workflows

- Achieved 1-2% reduction in material waste through clash detection and design optimization enabled by precise digital modelling, supporting sustainability and minimizing errors.

- Reduction of site visits and potential site material wastage or site rework

- Real-time models improved cross-discipline coordination

- Immersive Engagement with interactive 3D models through augmented reality

“Utilizing Bentley software on the PTA Sutherland St. Load Upgrade project significantly enhanced our efficiency and accuracy. The integration of Bentley's advanced tools enabled seamless collaboration, precise design, and effective communication, ultimately leading to a successful project outcome. The environmental benefits and cost savings achieved underscore the value of Bentley's solutions in delivering sustainable and high-quality engineering projects.

— Sean Lee, Country Director - Malaysia, APD Global

Solution

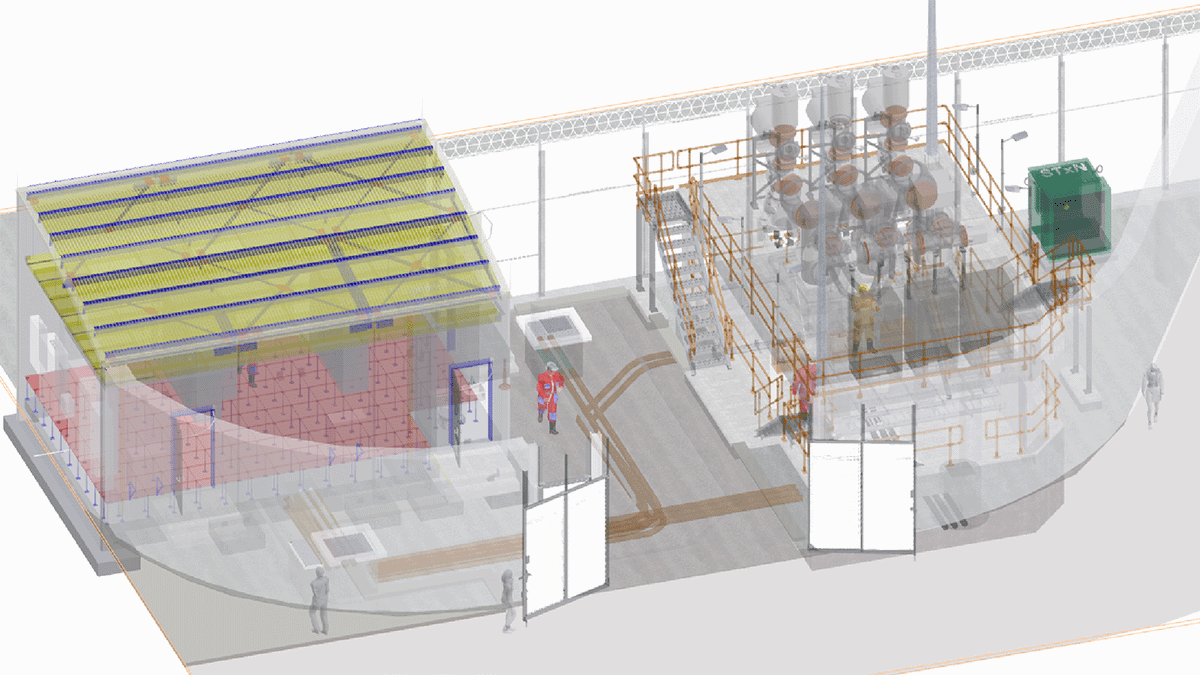

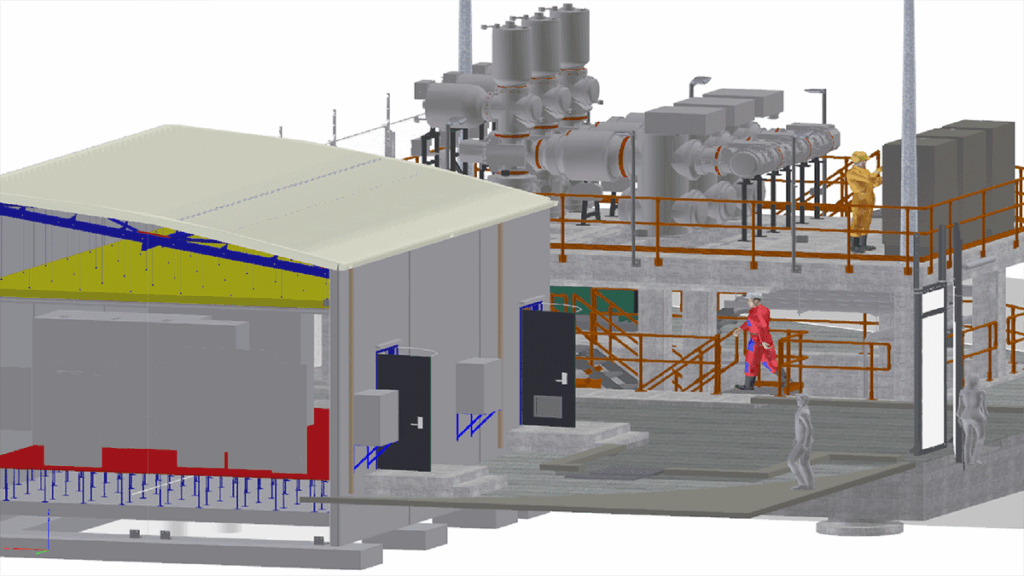

To overcome the challenges of fragmented workflows, limited visualization, and inefficient collaboration, APD Global adopted Bentley’s suite of integrated digital tools for the project. The team used MicroStation for detailed design and drafting, ensuring precision and compliance with engineering standards. OpenUtilities Substation supported utility network design and visualization, streamlining the planning of complex electrical systems.

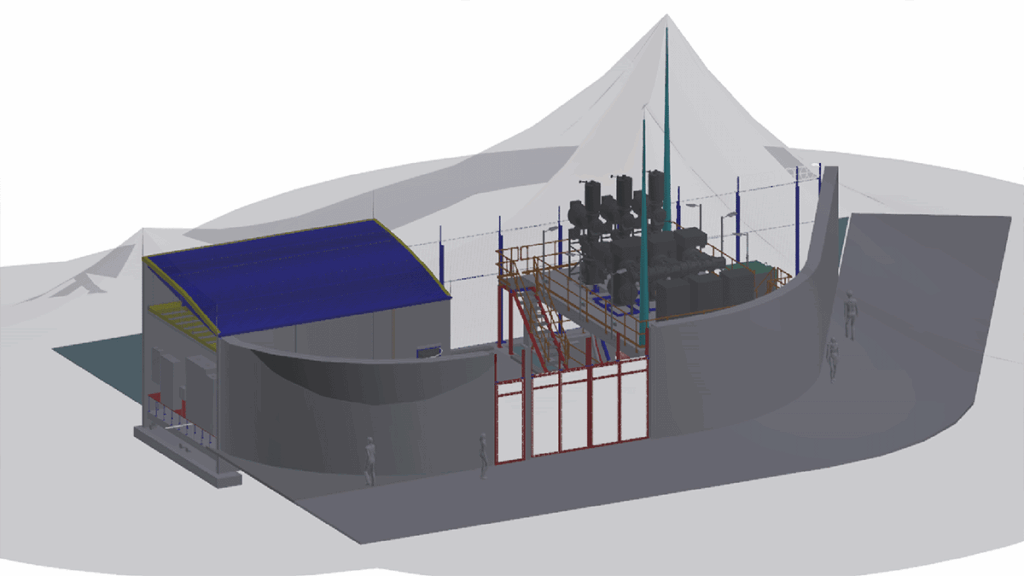

iTwin Capture was deployed to gather high-resolution reality data, enabling the creation of accurate 3D models that reflected existing site conditions. This data was processed using Bentley Descartes, which allowed for advanced point cloud modeling and seamless integration into design workflows. These tools helped align civil and structural elements with electrical infrastructure, reducing errors and improving coordination.

Bentley LumenRT helped create digital twins with immersive real-time visualization, making it easier to communicate project scope and progress to stakeholders. This enhanced understanding and alignment across teams. The use of ProjectWise ensured a single source of truth, facilitating real-time updates and collaborative reviews.

Together, these tools enabled automatic report generation, reduced manual errors, and minimized site visits. The digital-first approach improved efficiency, reduced material waste, and delivered a high-quality design that met all stakeholder expectations.

Outcome

The adoption of Bentley technology led to a 15% reduction in both design time and overall project completion time, translating into significant cost savings. Material waste was reduced by 1% to 2% through clash detection and optimized design. The project’s digital workflows improved collaboration across disciplines and minimized risks of delays and rework. Enhanced visualization and reality modeling ensured accurate alignment with existing infrastructure, while reduced travel and site visits contributed to a lower carbon footprint. Ultimately, the project delivered resilient and sustainable power infrastructure that supports Perth’s growing public transport needs and improves quality of life for its residents.

Software

Bentley software helped APD Global streamline design, improve coordination, and visualize the project in 3D. These capabilities led to faster delivery, reduced waste, and stronger stakeholder alignment. The software included:

- Bentley Descartes

- Bentley LumenRT

- iTwin Capture

- MicroStation

- OpenUtilities Substation

- ProjectWise

- Promis.e

Ready to transform your next power project? Explore how Bentley’s substation design and digital twin solutions can streamline your workflow and cut costs ❯.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.