One of the more common questions I get is,

“What is the target velocity I should achieve when I’m flushing a water main?”

As with most questions I’m asked, the initial response is, “It depends. Why are you flushing in the first place?” There are multiple reasons for flushing, including:

- Removing suspended solids from water mains

- Responding to customer complaints about dirty water

- Removing dissolved material from water mains

- Responding to customer complaints about taste and odor

- Pulling water with a good residual disinfectant into the area

Velocity matters significantly only for the first two items on the list. For the other three, velocity isn’t especially important. The problems with the first two items are caused by the suspension of solids and keeping them suspended in the flow. This depends heavily on the nature of the solids, including specific gravity, size, and cohesiveness. The most common culprits are iron and manganese. They may have carried over from the treatment process or, for iron, they may be a result of corrosion in unlined iron pipe. It may be a temporary problem triggered by a short-term high velocity from a fire or a pipe break.

Theoretical sidebar: It is not velocity that moves solids but the tractive stress between the fluid and the pipe wall/sediment. Tractive stress calculations are often used in determining if solids will move in sewers, but most water engineers/operators have a better understanding of velocity rather than tractive stress. Bentley’s OpenFlow Sewer can calculate tractive stress in sewer pipes.

The first step is to look at the dirty water and try to get a handle on the solids. If solids are detected, then the question becomes:

What does it take to move them? Next time you are flushing, you can do the following test:

- Find a pipe where you suspect there are solids.

- Try to isolate it so that flow comes to the hydrant from a pipe with known diameter in one direction, so that you can convert flow reading into velocity.

- Hook up a Pitot so you can measure flow (at low flow you may need a bucket and stopwatch).

- Open the hydrant a small amount long enough so that you can be sure you are getting water from the main and not just the lateral.

- Run until the water clears up; if it doesn’t, continue long enough that you feel the flow is no longer coming from the nearby main but from distant pipes; using a portable turbidity meter can be helpful. If possible, take a picture of the water in a glass beaker.

- Increase the velocity until the outflow becomes dirtier; note the flow rate (and possibly turbidity).

- Continue increasing the flow until the water is clear. (If it doesn’t clear up and increased flow makes no difference, this may mean that the test pipe is clean, but you may be drawing in solids from distant pipes.) Go back to 5 with the new flow rate.

- Continue until the hydrant is fully open.

Repeat this test at a few locations.

You should confine the sampling to the mains immediately upstream of the flowed hydrant. If you run the test too long, you’ll get contributions from other pipes where you don’t know the velocity.

When increasing the flow does not increase the solids, you have identified the minimum velocity to clean the pipe. You might want to add a small safety factor. The key is determining the velocity where the flow will dislodge the solids and keep them suspended until they reach the hydrant and increasing the velocity doesn’t help any further.

But many of you will say, “That test procedure is too much work. We just want a number.” I can understand that.

In sewers, we generally aim for a velocity of at least 2 ft/sec occasionally to keep the solids moving. If 2 ft/sec can move sewer solids, it should be good enough for water. Hopefully, your drinking water is of higher quality than your sewage. (If not, you have other problems.) But sewer solids tend to have a specific gravity close to one, and drinking water solids may be a bit more dense.

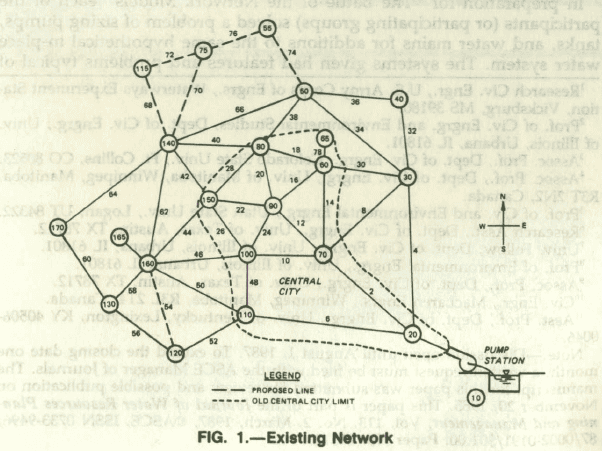

For any solid there is some velocity (tractive stress) in the pipe below which it will settle, and the pipe acts as a long clarifier. The peak velocity in many pipes on a normal day is very low (i.e., much less than 2 ft/sec). You can run your hydraulic model for a peak hour demand to find these pipes which can become sediment reservoirs (i.e., very low velocity). These are the areas that will most likely need flushing. On the other hand, large transmission mains usually run at a high velocity and won’t need flushing because nothing will settle in them. (This is good because it would take a huge flow to flush them.) Pipes with normally high velocity are essentially self-cleaning.

The implications for some examples are:

- If you want to flush a main that has a peak daily velocity of 0.2 ft/sec, 2 ft/sec may be adequate.

- If you want to flush a main that has a peak daily velocity of 2 ft/sec, 4 ft/sec may be adequate.

- If you want to flush a main that has a peak daily velocity of 4 ft/sec, you may not need to flush.

However, there may be situations where the solids are not just settled but are attached to the pipe and need a much higher velocity to be moved. Once you have confirmed that these velocities (say 8-10 ft/sec) are necessary, that can become your target. With such solids, foam pigging, ice pigging and other methods may be more useful than flushing. Removing biofilms is especially tricky. I haven’t found a way to measure biofilms in the field.

The above has implications on flushing methods to be used. In recent years, unidirectional flushing (UDF) has become more popular. It differs from conventional flushing in that the crews isolate specific pipes to be cleaned by operating valves. With conventional flushing, valve operation is usually not required. UDF is significantly more expensive in that it requires larger crews, takes much longer, and requires extensive planning. (OpenFlows Water can help you do this.)

Conventional flushing is much less resource intensive. You just need to follow what I call Gangemi’s Law, “Always flush with clean water behind you.” It is much easier to use OpenFlows Water to check if conventional flushing will meet your needs than checking UDF. UDF requires that you define each valve and hydrant operation in sequence.

As usual, I have disappointed everyone who expected a quick answer to the question I posed in the title of this blog.

Read more of Tom’s blogs here, and you can contact him at [email protected].