Shanghai Investigation, Design & Research Institute Co., Ltd. / China Three Gorges New Energy Dalian Zhuanghe III Offshore Wind Farm Project

bohai sea, china

Project

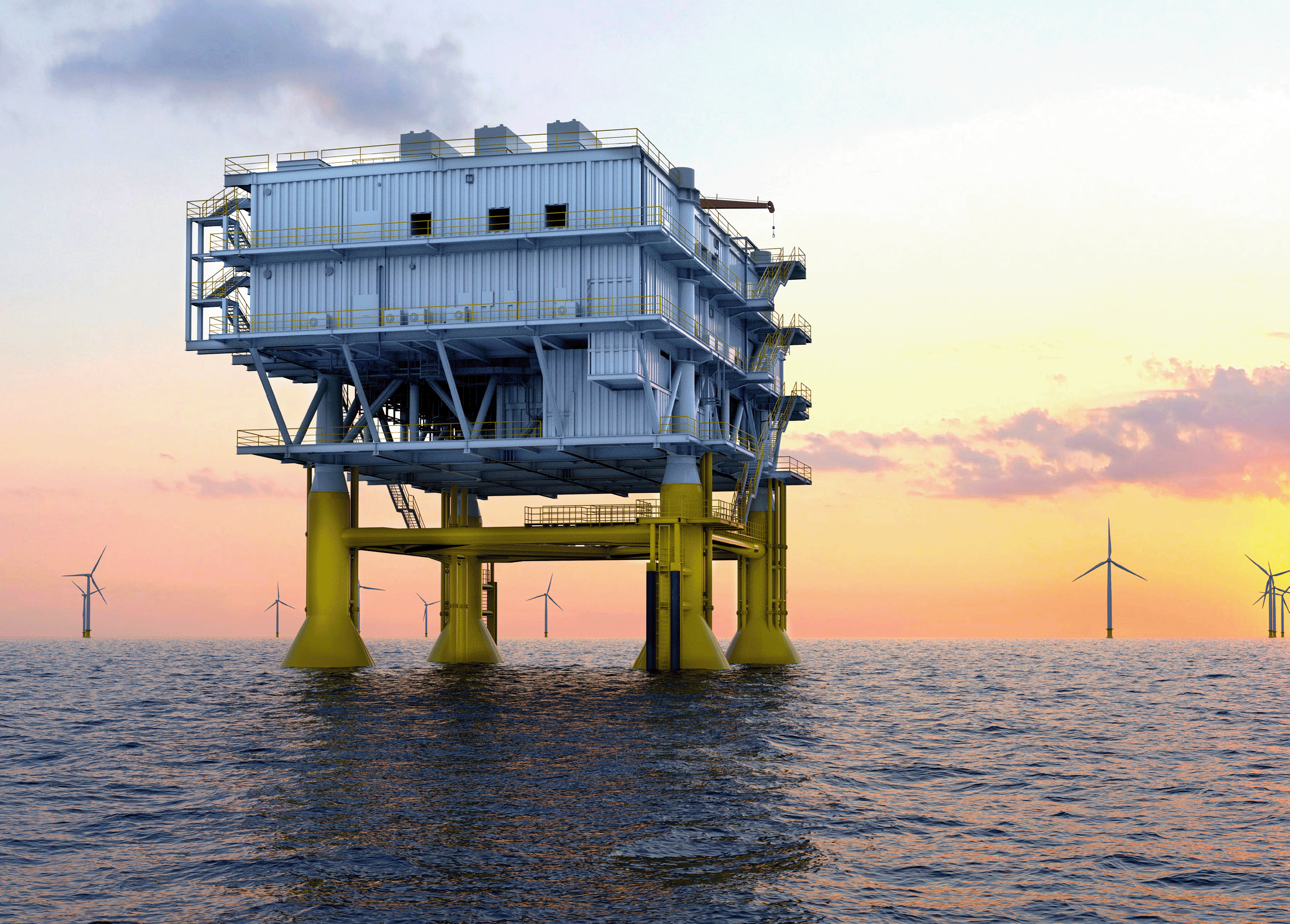

China Three Gorges New Energy and Dalian Power Generation, owners of multiple offshore wind developments in China, contracted Shanghai Investigation, Design, & Research Institute (SIDRI) to design an offshore wind farm in the Bohai Sea. The large project, including 72 wind turbines with a combined capacity of 300 megawatts and a 220-kilovolt booster station, would be built among the trenches and caves of the local sea floor. Additionally, the design would have to protect the wind towers from ice floes during the winter months. The size, complexity, and challenges of this project presented what SIDRI called “second-to-none” difficulty.

Facts

- 3D design applications helped optimize wind farm design, overcome uneven terrain, and protect wind towers from seasonal ice floes.

- By conducting all work in an open, digital iTwin connected data environment, SIDRI discovered and resolved over 80 clashes, saving 570 resource days and CNY 3 million.

- In total, 3D modeling improved overall designs, shortened the design process by three months, and saved CNY 50 million.

“With SACS Wind Turbine, the design team iterated designs to determine the best way to protect the tower foundations from ice damage. Their work resulted in anti-ice cones, which flare out where the tower meets the water. The design … protects the tower foundation by providing a much thicker surface area that deflects floating ice more effectively than a narrower surface.”

– Fei Jin, BIM Manager

Solution

As the deadline was too tight to use traditional 2D design methods, SIDRI turned to 3D BIM applications using OpenPlant and OpenBuildings to create a digital iTwin model of the entire wind farm, including an offshore substation platform. The design team analyzed the complex offshore terrain, determined where the subsea soil could accommodate wind tower loads, and optimized foundation design. Iterative 3D modeling allowed the team to improve all aspects of the wind farm’s design, including the creation of anti-ice cones. By thickening the area of the tower in a cone shape at the water’s surface, ice floes would more effectively deflect off the tower than a narrower surface. Additionally, the design team created a custom steel structure joint model library in the 3D design applications, which automated the placement of steel structure joints.

Outcome

By conducting all work in an open, connected data environment with an accurate digital iTwin model, SIDRI discovered and resolved over 80 clashes, saving 400 resource days of design modifications, 100 resource days of proofreading, 70 resource days of on-site error handling, and CNY 3 million in additional expenses. In total, 3D design and visualization helped the design team save 500 resource days of design time and CNY 50 million, all while optimizing design elements and overcoming terrain and weather challenges. SIDRI plans to apply similar design techniques to future offshore wind farm development, which will save an estimated CNY 5 million per project.

Software

SACS Wind Turbine

SACS Wind Turbine allowed SIDRI to analyze the complex terrain, predict structural performance, and optimize foundation design. Components for individual 3D digital iTwin models were created using OpenBuildings Designer, Bentley Raceway Design and Cable Management, OpenPlant, and ProSteel, all of which improved the efficiency of the multidiscipline engineering design across structure, piping, mechanical, and electrical areas. SIDRI established its open, connected data environment with ProjectWise. All the individual designs were federated in Navigator, which allowed the team to collaborate, but also detect and resolve clashes automatically.