Modeling and analyzing pressure vessels to be accurate and safe enough to withstand high temperatures and pressure processes can be expensive and time-consuming. With advanced capabilities and comprehensive databases, AutoPIPE Vessel has been proven to enable engineers to deliver greater productivity, cost-effective manufacturing, improved project collaboration, and truly optimized pressure vessel designs.

Here are seven AutoPIPE Vessel features that can help you and your team produce your most accurate and reliable vessel designs:

01. Automation and design check

Manual calculations can be extremely time consuming, which can lead to project delays. AutoPIPE Vessel’s advanced automation and design check capabilities can give you the solution to maximize your productivity and minimize errors by eliminating guesswork and filling in the gaps for you. Feel confident that your designs are accurate, cost-effective, and code compliant.

Color-coded data sets let you see what information is required and what can be generated by the software. For example, input your available information into the required fields (red), and, from that information, other values (green) can be calculated for you.

If you are in a pre-dimensioning or cost estimation phase, speed and simplicity is a must. AutoPIPE Vessel guides you through the design process by suggesting solutions for you to adopt or to adapt as you work, eliminating the need for manual iterations. Take control during check mode at any time to get the results you need.

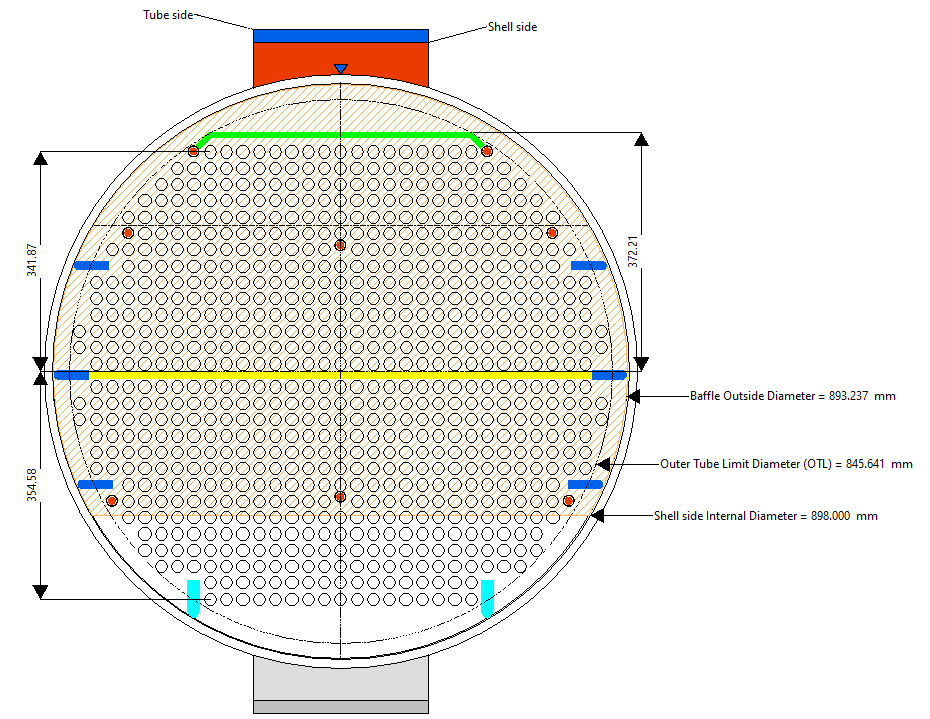

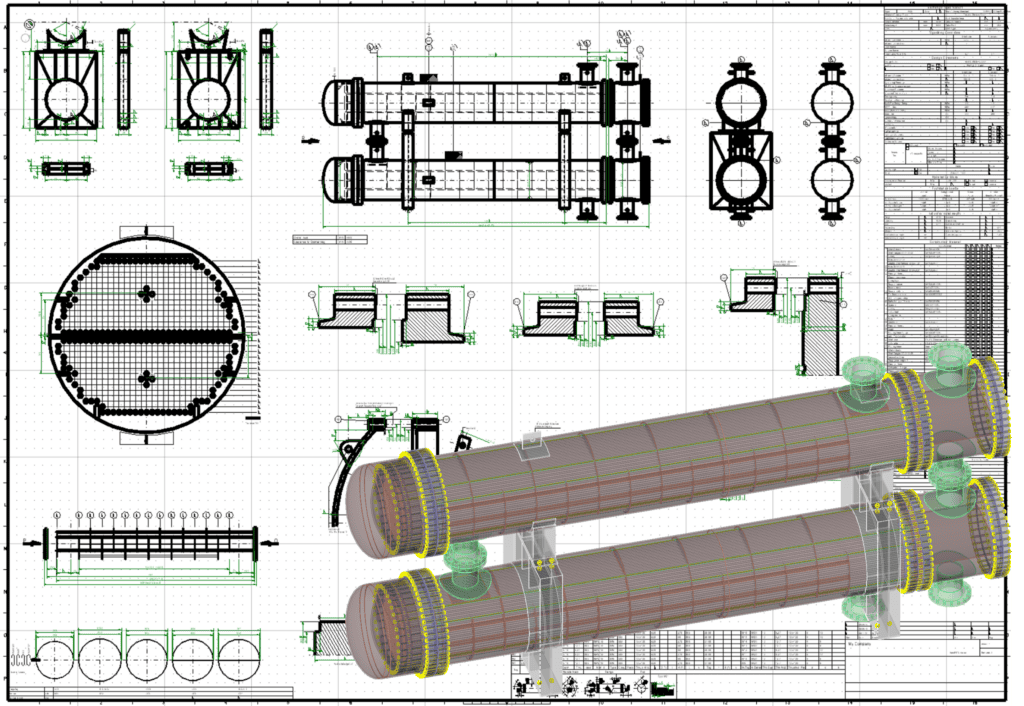

02. Bundle layout design

Manual tube design and rendering often takes hours and can be highly complex. With AutoPIPE Vessel, you can design a center tube and a vertical offset, or even choose your tube pitch type and let our software create the pattern for you. Our simple user interface makes it easy to make almost any adjustment to your vessel bundle, ensuring you get the layout you need. With AutoPIPE Vessel, you can:

- Design your bundle layout based on the number of tubes and the outer tube limit diameter of the inside diameter of the shell. Choose your tube pitch type and let the software create the pattern for you. Need a center tube or a vertical offset? It’s done with a click.

- Use AutoPIPE Vessel’s menu bar to adjust sealing rods, sliding rails, order of passes, dummy tubes, un-tubed areas, and more during the design process. Select your desired material and plug and place with the click of your mouse.

Set impingement plate attachment and position, include the pressure drop per pass of your partition plate, and input tie rods using your mouse. If you’d like, you can use diameter coordinates to place tie rods yourself. Feel free to use automation, or opt for manual input depending on your design needs.

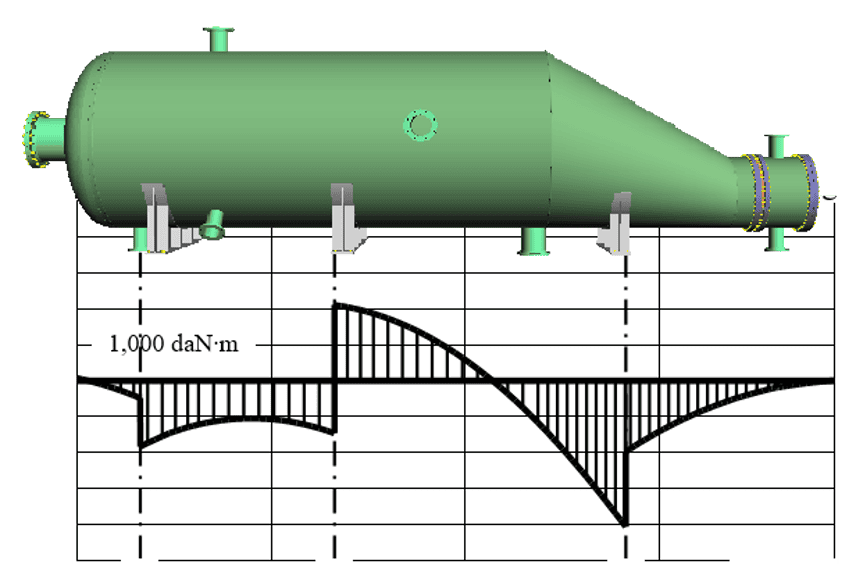

03. Support check and calculation

Support optimization is a crucial part of vessel design. AutoPIPE Vessel utilizes finite element analysis methods to calculate load distribution, efficiently and accurately handling statically indeterminate or non-symmetrical vessels in ways other software cannot.

Support legs are checked when the load is applied on one leg as well as in the middle of two, considering code validated load distribution. The fundamental frequency determination through the eigen vector provides the proper mass distribution under an earthquake load, ensuring you develop a more reliable vessel in cases of extreme load stress.

You can check the changes suggested by our software in the “Summary of Changes” section, giving you an overview of vessel changes made to improve quality and cost of design.

04. Material database

AutoPIPE Vessel contains an extensive materials database that is pre-loaded with more than 2,000 materials to meet a variety of supported codes. This library is also highly customizable to fit your project needs, helping you maximize your productivity and minimize errors.

The material manager enables you to find, print, copy, add, and understand materials easily. These materials can be edited within the database at the model level and at a component level to limit their scope. Thermal expansion and elasticity modulation groups are already included, which will help to streamline your workflow and avoid errors.

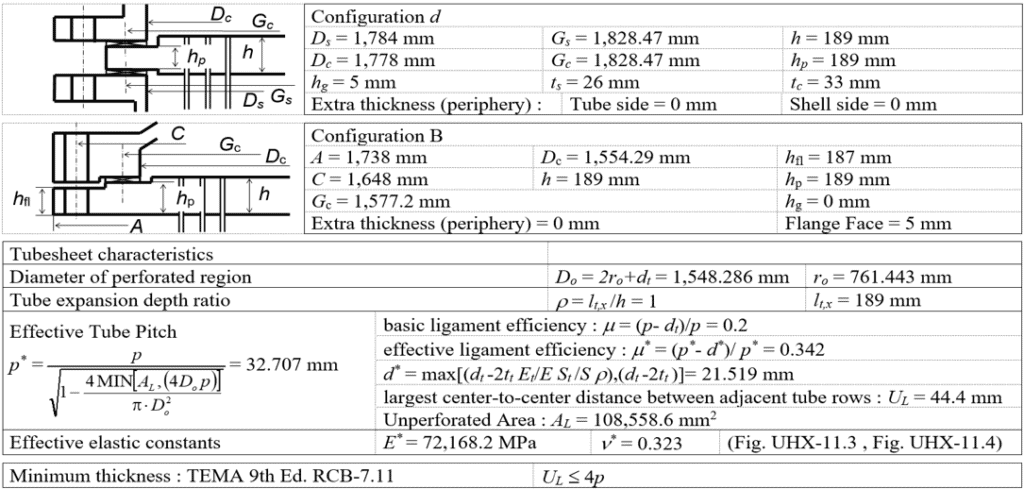

05. Top-notch reports

Simulation reports are the best way to understand your vessel’s reaction to various load types. AutoPIPE Vessel reports include images, code equations, and all paragraphs’ references, making them easy to understand.

Reports go step-by-step to ensure you have the best understanding of your vessel and can address durability issues. You can also customize your report’s first page, headers, and footers, saving time on repetitive edits.

06. 3D and 2D drawings

Drawings are an essential part of the pressure vessel design process. AutoPIPE Vessel’s advanced drawing features reduces manual drawing time and rework with automated, detailed drawings and components development to increase competitiveness and profitability.

Detailed 2D and 3D drawings can be created instantly with customizable data and connection details, white space management, and configurable drawing sheet layout to meet your project needs. 2D drawings can be printed in both .dgn and .dwg file formats, while 3D models can be exported in Industry Foundation Classes (IFC) or SolidWorks.

Create fully dimensioned engineering and manufacturing drawings with support for manufacturing component details and installation and operating conditions. Additionally, a primary flat view can be generated on the user interface.

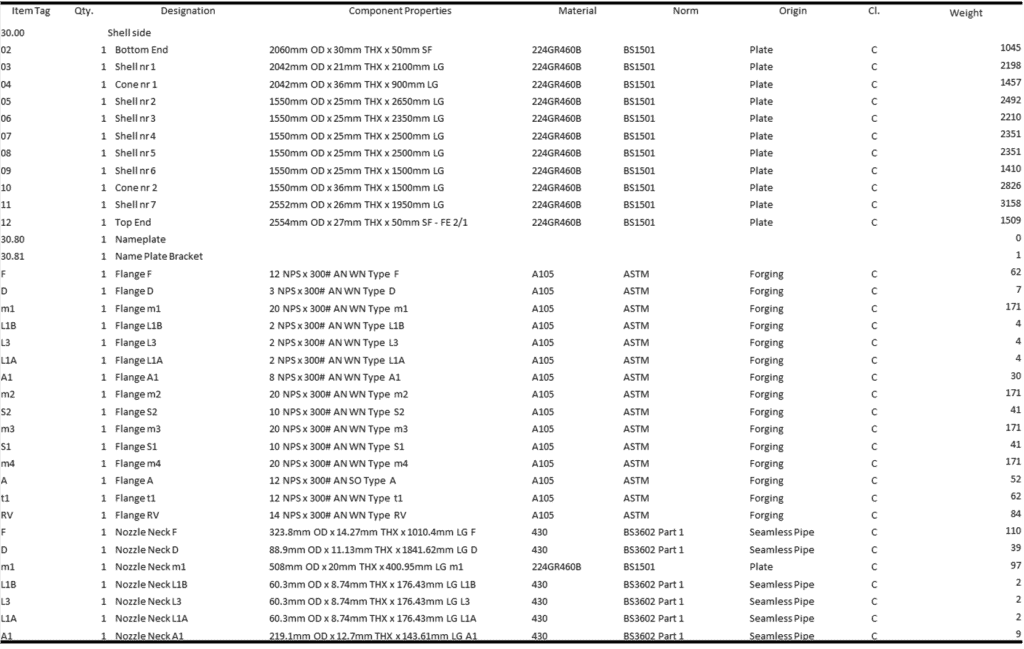

07. Bills of materials

Compiling a bill of materials can be the most time-consuming part of any design project. AutoPIPE Vessel automatically generates a bill of material in Microsoft Excel for any vessel to meet company standards.

This includes all your must haves: material, weights, and reference to locate and purchase components. Our automated process allows you to cut hours of manual calculation work into seconds.

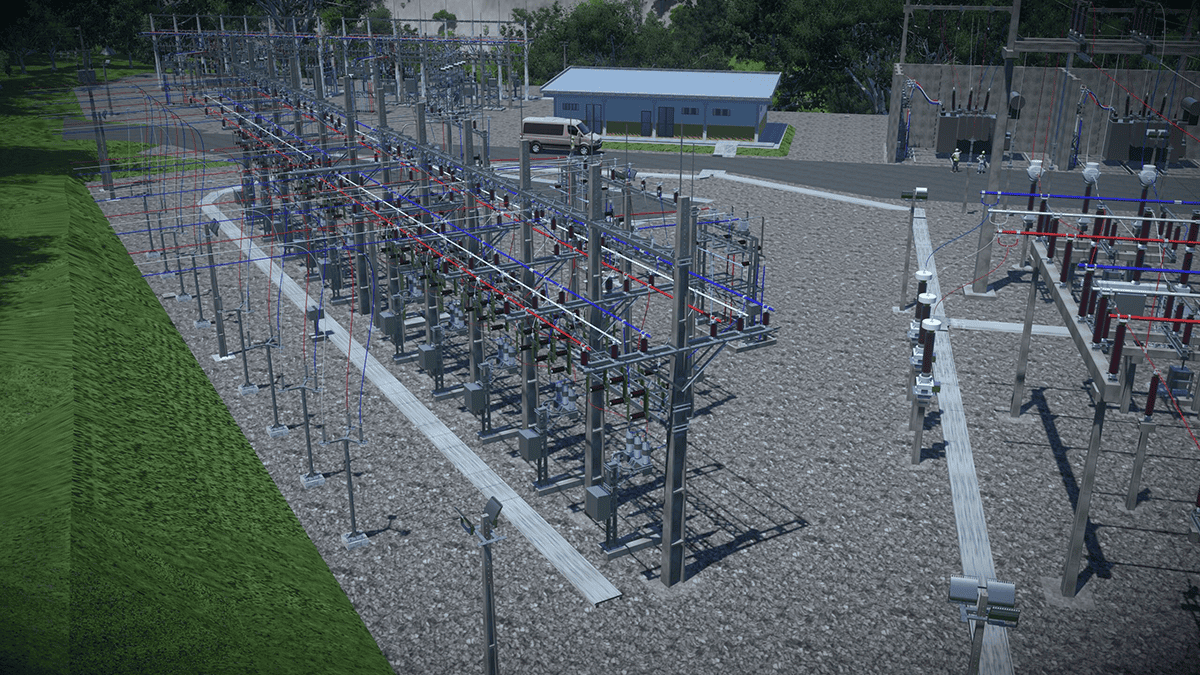

AutoPIPE Vessel stands out as a robust solution for designing complex pressure vessels and shell and tube heat exchangers under various loading conditions. Its extensive suite of global and regional pressure design code standards, automated workflows, detailed equipment cost estimation, and clear step-by-step reports ensure you can deliver accurate, safe, and compliant designs on time and within budget.

Discover the future of vessel design with AutoPIPE Vessel.