Revolutionizing Pavement Assessment with AI: Benesch Leads the Way

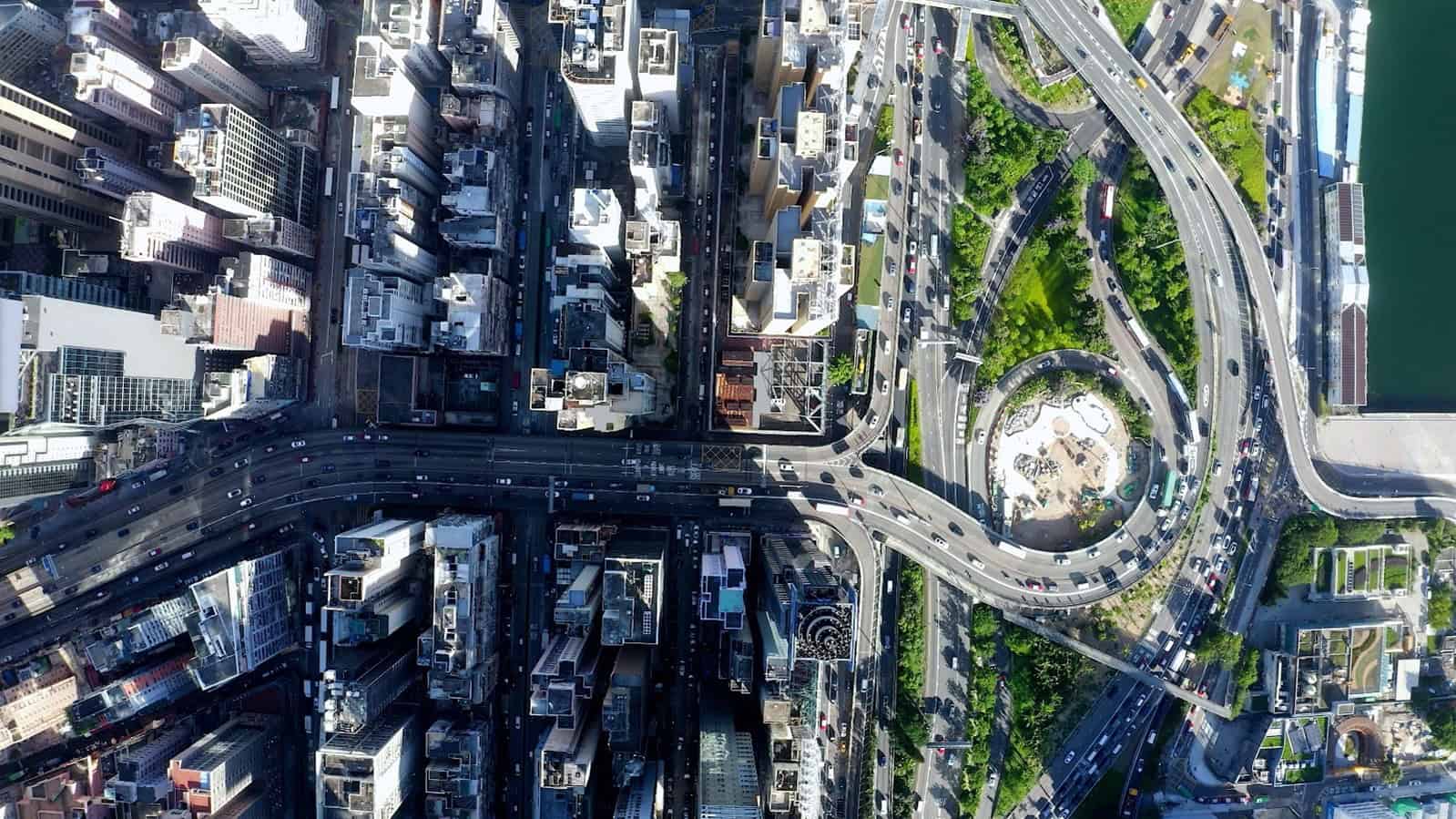

Artificial intelligence is actively transforming the present. From roads to runways, AI is redefining how we inspect, maintain, and plan critical assets. By integrating technologies like digital twins and machine learning, engineering firms are streamlining routine assessments and taking infrastructure management to a new level.

Benesch, a visionary engineering and professional services firm based in the United States, is leading this transformation. Armed with cutting-edge AI tools, Benesch is reimagining pavement assessment, making it faster, smarter, and safer than ever before.

What is a digital twin?

A digital twin is a digital representation of a physical asset, process, or system, as well as the engineering information that allows us to understand and model its performance.

Typically, a digital twin can be continuously synchronized from multiple sources, including sensors and continuous surveying, to represent its near real-time status, working condition or position.

A digital twin enables you to visualize the asset, check status, perform analysis, and generate insights in order to predict and optimize asset performance.

The challenges with conventional inspection methods

For decades, pavement inspections have been a labor-intensive job—inspectors walking or driving over surfaces, photographing cracks, and manually analyzing damages. While this approach has been the standard, it’s far from perfect.

• Time-consuming and expensive: Large-scale assessments could take days or even weeks.

• Risky for workers: Inspectors operate in hazardous conditions, sometimes in high-traffic areas.

• Disruptive to daily operations: Lane closures and restricted access create bottlenecks.

• Prone to human error: Manual assessments may overlook critical defects.

With deteriorating infrastructure demanding urgent attention, Benesch recognized the need for a smarter, data-driven approach.

The impact of AI-powered pavement inspections

Benesch’s AI-driven approach is more than just a technological upgrade—it’s a game changer for infrastructure maintenance. Their success in real-world applications shows that AI-powered pavement detection can save time, reduce costs, and improve safety.

• 75% faster inspections: Airports, highways, and bridges can be assessed in a fraction of the time.

• $USD 144,000 in expected cost savings: Efficient inspections reduce labor expenses significantly. This is what Benesch expects to save while inspecting 100 future airports.

• Improved accuracy: AI ensures reliable and consistent crack detection.

• Enhanced worker safety: Removing inspectors from high-risk environments minimizes potential hazards.

• Minimal disruptions: Airports and roads remain operational throughout assessments.

Looking ahead: AI’s role in smarter infrastructure

Benesch is setting a new standard for pavement inspections, demonstrating how digital twin technology and artificial intelligence can revolutionize civil engineering. Its vision extends beyond individual projects, aiming to create a scalable smart pavement detection application that could benefit cities, states, and industries worldwide.

As global infrastructure ages, Benesch’s’ AI-driven solutions pave the way for smarter decisions and sustainable maintenance.

Explore how Bentley’s iTwin Capture Cloud Services are enabling teams like Benesch to lead the way in smarter pavement assessments.