Seismic rehabilitation of creeping ground using a sustainable micropiled PT raft

Organization: GeoStruxer

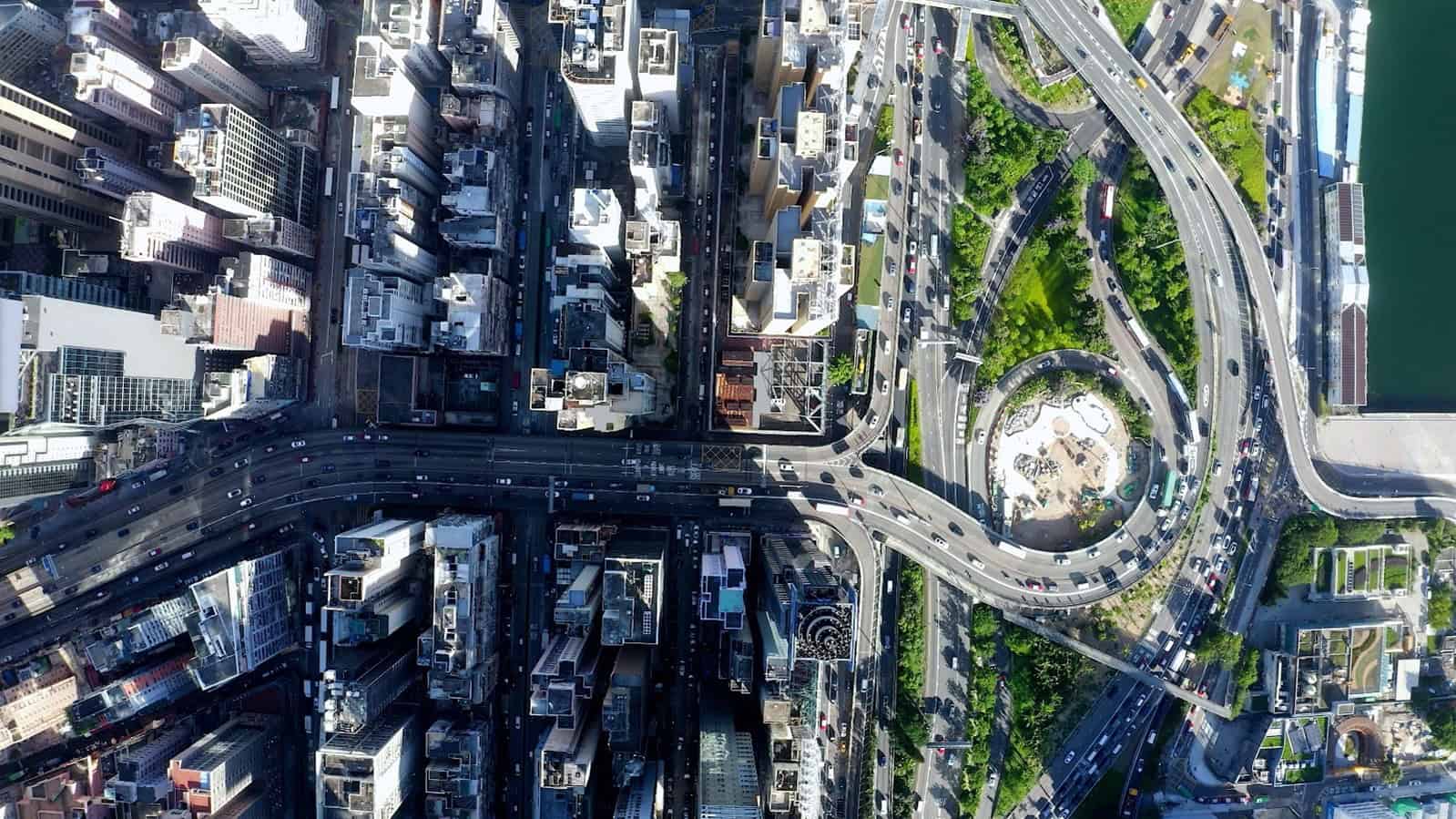

Location: Jazan, Saudi Arabia

Project phase: Completed and operational

Estimated project cost: USD 5.4 million with a 2.1 million cost savings from optimization

Bentley software: PLAXIS, RAM

Additional context: The grain warehouse is a critical food security hub serving over 1.5 million people, making the uninterrupted operation and long-term resilience of the facility vital to the community.

Project: Securing critical food security infrastructure

Jazan, located on the Red Sea coast of Saudi Arabia, is home to a vital 12,000-square-meter operational grain warehouse that serves as a critical food security hub. The original foundation, a slab-on-grade supported by bored piles, was failing because it was built on extremely unstable ground with Sabkha soils and underlying salt domes prone to long-term creep deformation. The structure was experiencing severe differential settlement, threatening its structural integrity and seismic resilience. The design team’s mission was to develop a sustainable, safe, and cost-effective rehabilitation solution that could mitigate both the ongoing creep and the seismic risks, all without disrupting the warehouse’s crucial, continuous operation.

Facts

- Critical infrastructure: The 12,000-square-meter-grain warehouse is a vital food security hub, serving over 1.5 million people. Its structural stability is essential for regional food security and resilience.

- Extreme geotechnical conditions: The ground consists of highly challenging materials, including Sabkha soils and active salt domes, which lead to aggressive chemistry and long-term creep deformation that is extremely difficult to model and control with conventional methods.

- Severe original failure: The structure suffered differential settlements of up to 170 millimeters, which severely compromised its functionality, threatened structural collapse, and reduced its capacity to withstand seismic events.

- Operational constraint: The entire rehabilitation process was required to be completed while the warehouse remained fully operational, posing significant logistical, safety, and operational challenges for the foundation retrofit.

- Digital cost optimization: The project achieved USD 2.1 million in direct cost savings by using the digital twin approach to optimize the foundation design, replacing a highly conservative, expensive original concept with the lighter, more efficient combined micropiled post-tensioned raft.

"The project provides a strong and comprehensive sustainability case across Envision categories, particularly related to community benefits, material efficiency, environmental protection, resilience and carbon emissions reduction, and cross-sector innovation.”

- Anthony Kane, president and CEO of the Institute for Sustainable Infrastructure

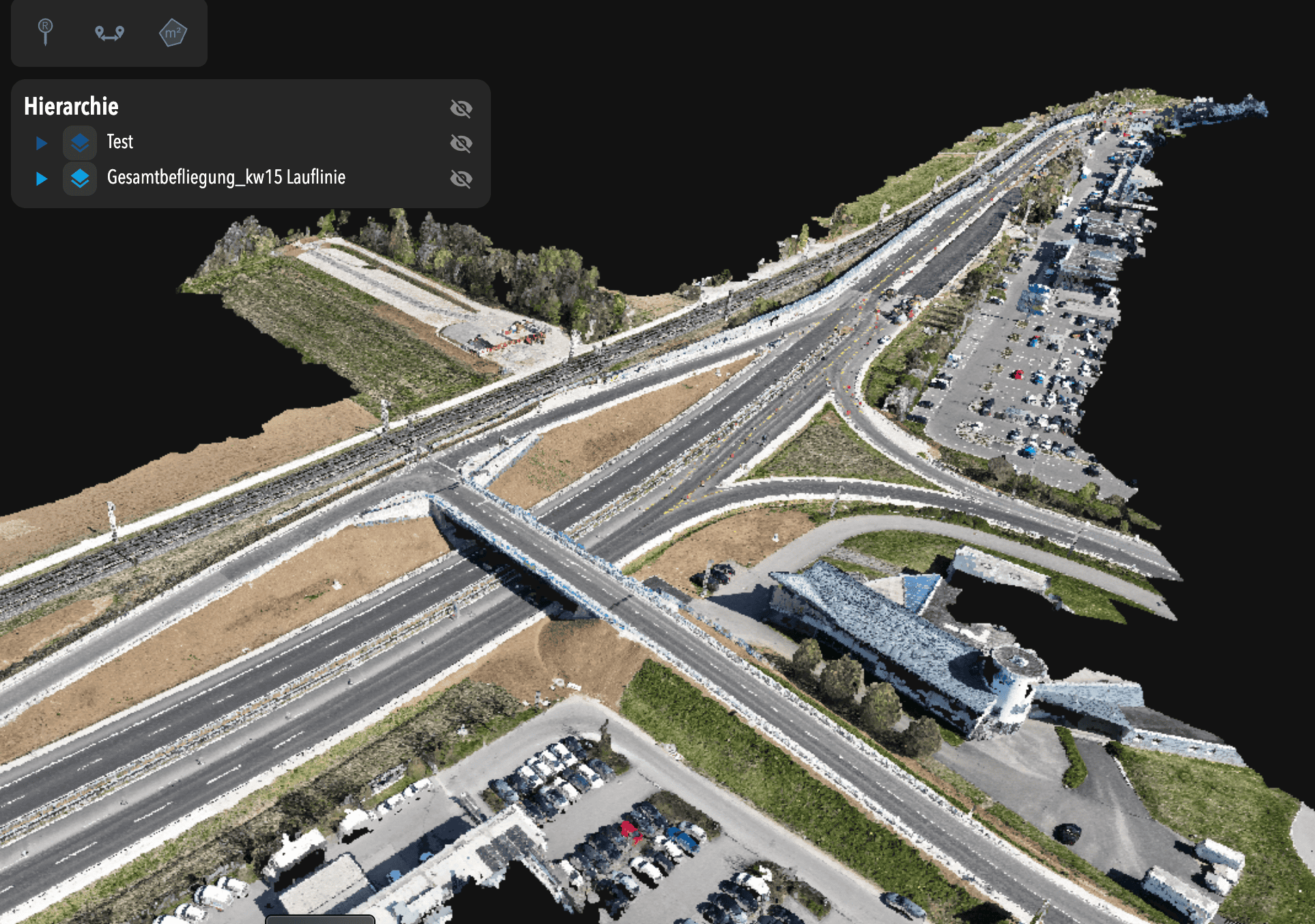

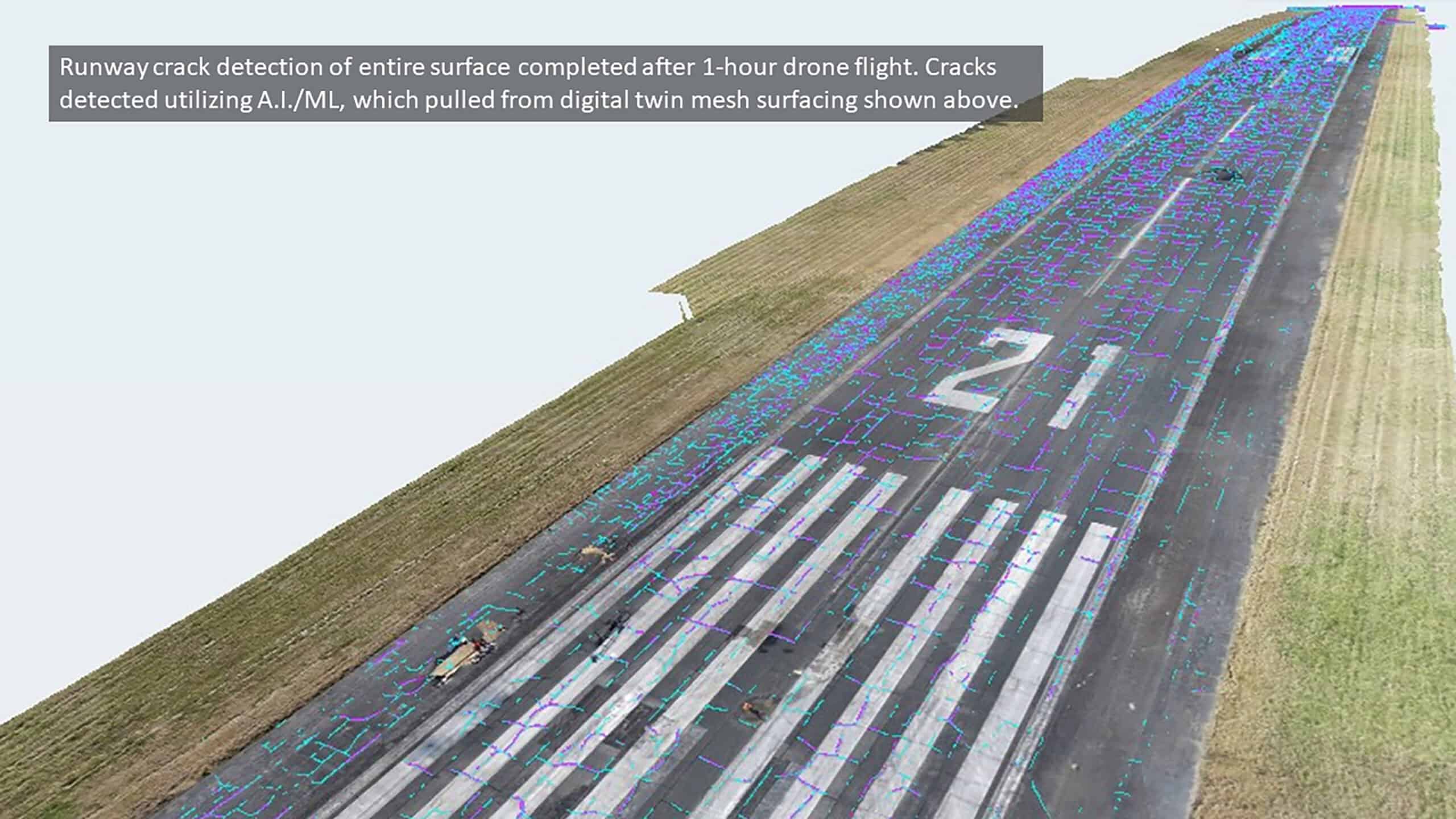

Solution: A geotechnical digital twin calibrated by satellite data

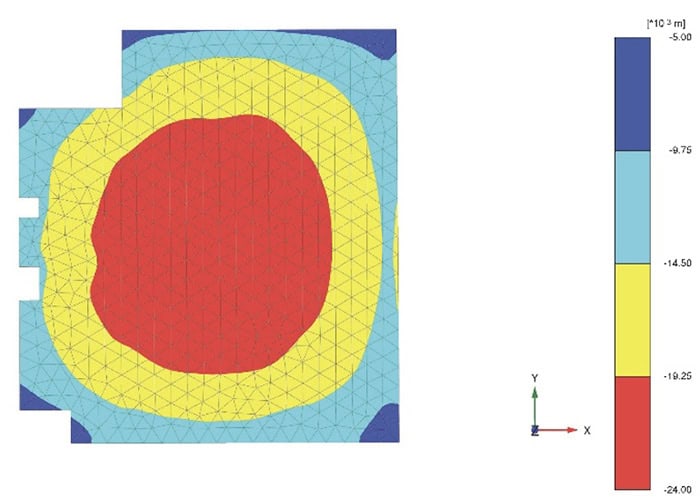

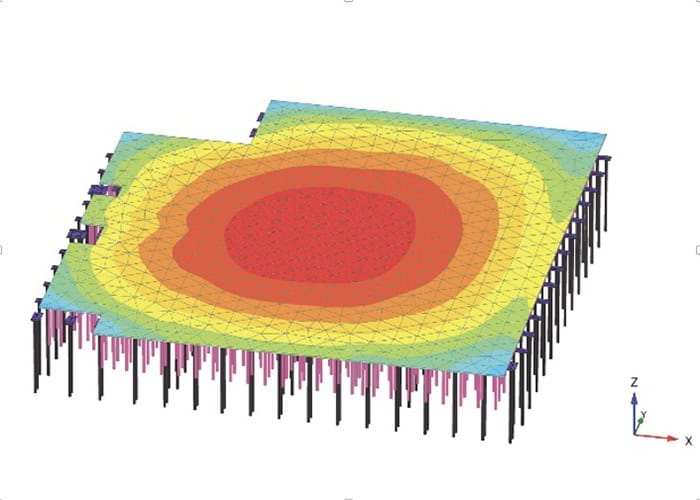

GeoStruxer developed a revolutionary, digitally driven methodology centered on creating a high-fidelity geotechnical digital twin. This approach allowed the team to move away from the failing traditional concept to a highly optimized combined micropiled post-tensioned raft (CMPRF) system.

This type of system is a foundation solution that integrates a post-tensioned concrete raft with a reduced number of strategically placed micropiles to share loads efficiently between the structure and the ground. By actively engaging both the raft and micropiles, it improves settlement control, resilience, and sustainability while significantly reducing material use, cost, and carbon footprint compared to conventional piled foundations.

The crucial innovation was linking the 3D modeling environment to real-world performance data. GeoStruxer utilized AI-assisted calibration to integrate historical InSAR satellite monitoring data, which precisely detailed the settlement history. This allowed the model to implement the Norton Double Power Creep (N2PC) model, accurately predicting long-term deformation and enabling reliable forecasting for the 20-year design life.

Outcome:

- Massive cost and material savings: The digital design led to a 70% reduction in the number of micropiles (from 2,700 to 779). This optimization directly saved USD 2.1 million in construction costs—38% of the foundation budget—and conserved 1,200 tons of steel as well as a reduced volume of concrete.

- Significant carbon reduction: The material optimization resulted in a 44% reduction in embodied carbon, equivalent to saving approximately 2,000 ton of CO2 emissions, significantly supporting Saudi Vision 2030’s sustainability goals.

- Enhanced long-term resilience: By accurately modeling the creep, the project greatly reduced predicted long-term deformation compared to the original design concept, securing the grain warehouse’s future operation and verified seismic safety.

- Accelerated design cycle: The integrated digital workflow reduced the design cycle time by 35%, allowing the complex soil-structure interaction and post-tensioned design to be completed in under eight weeks, saving over 900 engineering hours.

The combined digital workflow transformed a geotechnical failure into a benchmark for resilient, low-carbon, and highly cost-efficient infrastructure rehabilitation in challenging coastal environments globally. As Anthony Kane, president and CEO of the Institute for Sustainable Infrastructure, noted: “The project provides a strong and comprehensive sustainability case across Envision categories, particularly related to community benefits, material efficiency, environmental protection, resilience and carbon emissions reduction, and cross-sector innovation.”

Software

The digital twin workflow relied on the integrated power of Bentley’s geotechnical and structural solutions:

- PLAXIS 3D: Used for advanced geotechnical modeling and long-term performance prediction. PLAXIS was key to implementing the sophisticated N2PC model and calibrating the soil parameters against the InSAR satellite data, which allowed the team to precisely simulate and control the complex, time-dependent creep deformation and analyze the soil-structure interaction under seismic loads.

- RAM Concept: Used for the structural design and optimization of the post-tensioned raft. RAM Concept ensured the efficient design of the slab to manage the stresses and potential residual differential movements while minimizing material usage, which was critical for the embodied carbon reduction targets.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.

Read more about the husband and wife team that led this project ❯