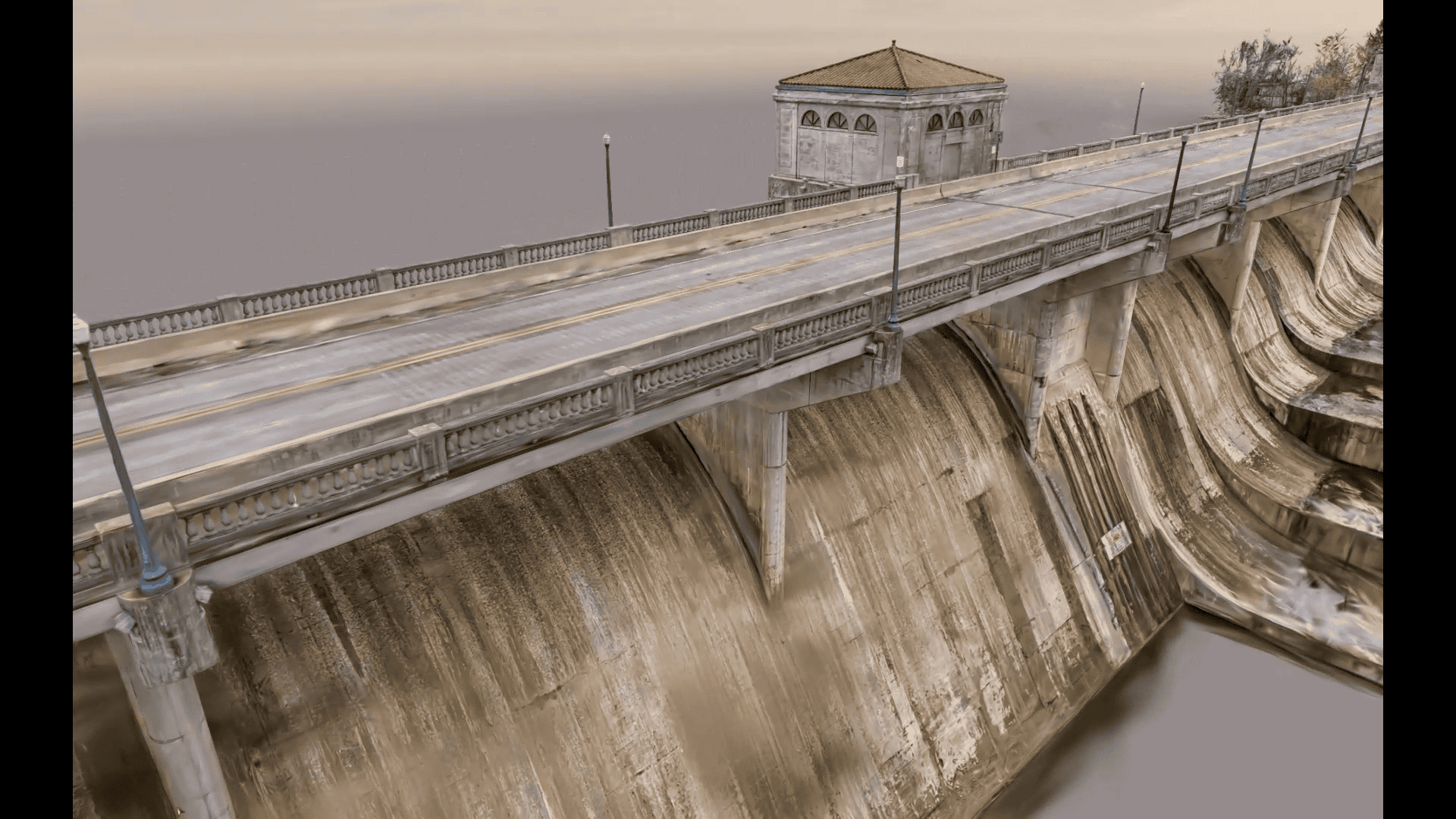

When we think of a foundation, we tend to picture what’s visible: the concrete slab under a bridge, the finished pavement of a highway, or the portal of a tunnel cutting into a hillside. These are the physical starting points that we can see, touch, and measure.

But real foundations, especially in transportation infrastructure, start where we can’t see. They begin in the layers of soil, rock, and groundwater beneath the surface. If those conditions aren’t well understood or accounted for early on, they can easily become the most unpredictable and expensive elements of a project.

Why the subsurface matters more than ever

Unforeseen ground conditions are one of the top causes of delays and cost overruns in transportation projects. According to the 2024 CRUX Insight Report, they’re the second most common reason for construction claims globally. Obscured ground conditions aren’t just about minor setbacks; they are a growing risk that can derail entire project timelines and budgets.

Many of our transportation systems are aging, built at a time when geotechnical standards were less rigorous or based on limited data. At the same time, environmental pressures—including flooding, subsidence, and extreme weather—are increasing, adding strain to infrastructure that may already be sitting on unstable ground.

These challenges are compounded by systemic industry pressures: geotechnical investigations require specialized expertise and funding that many agencies struggle to secure. Workforce shortages create bottlenecks in the early, critical phases of projects. Once projects begin, siloed data, outdated processes, and fragmented communication often prevent subsurface insights from reaching the right people at the right time.

In this environment, reacting to surprises is more common than preventing them. To break this cycle, project teams need tools and workflows that connect disciplines, streamline data, and enable agile responses from the start. Understanding the subsurface isn’t just a geotechnical issue, it’s a project delivery imperative.

Seeing beyond the surface

Infrastructure projects have traditionally prioritized what’s above ground: road alignments, bridge spans, drainage, and utilities. These elements are vital, of course, but they all depend on the unseen ground conditions below.

When subsurface considerations are treated as a separate phase, often handled by different teams using disconnected tools, critical insights can get lost. Ground investigations may be completed without clear links to design. Borehole data might not be shared. Geological models can become outdated the moment new information comes to light.

This leads to a familiar scenario: designs proceed based on assumptions. The result is all too familiar: crews uncover unexpected rock or groundwater mid-construction. Rework begins, schedules slip, budgets stretch, and safety is compromised.

Laying a better foundation with connected data

What if subsurface understanding wasn’t a separate step, but an integrated part of your entire infrastructure project lifecycle?

That’s the approach Bentley and Seequent are enabling. Seequent, the Bentley Subsurface Company, is the global leader in subsurface software. Understanding what lies beneath isn’t just part of what we do, it’s our sole focus and our deepest expertise. By combining Seequent’s trusted tools with Bentley’s civil infrastructure design solutions, we help teams bridge the gap between above and below ground, turning hidden risks into shared understanding.

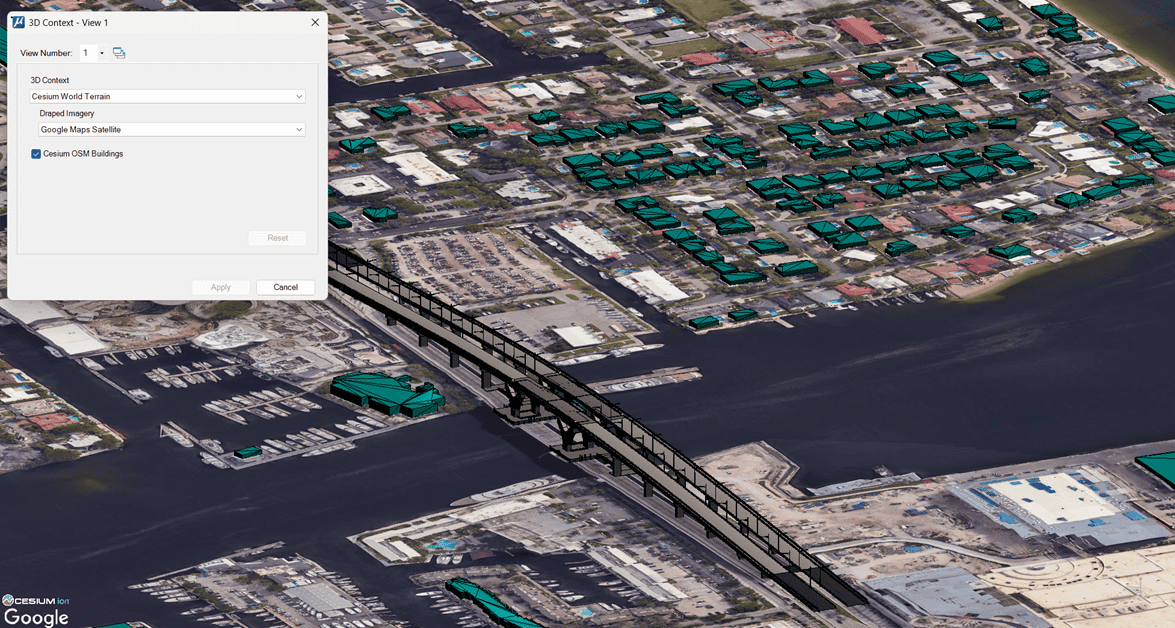

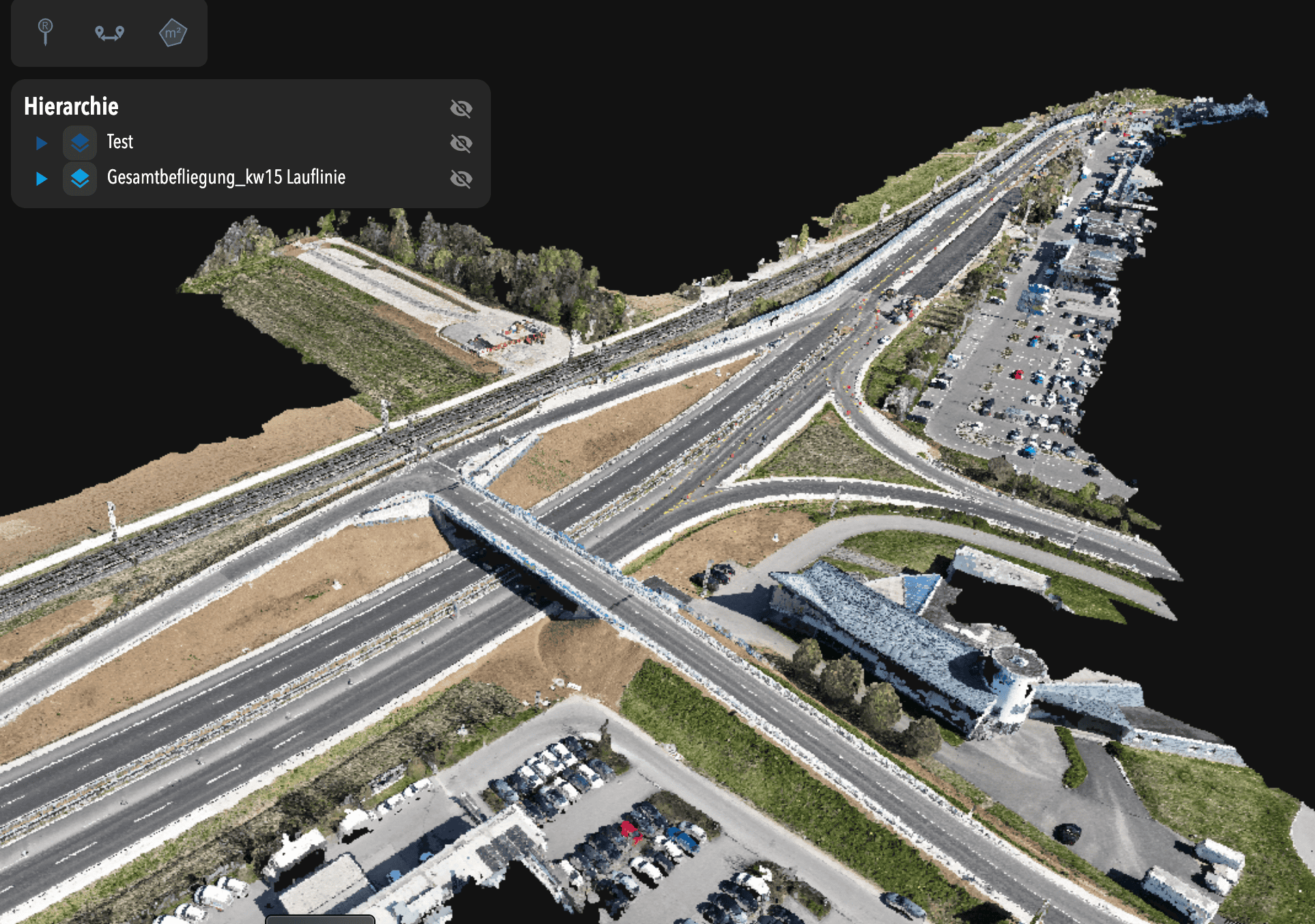

By connecting advanced geotechnical and geological modeling tools, like with transportation design solutions like Bentley OpenRoads, Bentley OpenRail, Bentley OpenBridge, and Bentley OpenTunnel, project teams can visualize, analyze, and update their understanding of ground conditions in real time.

This kind of integration enables:

- Smarter planning: Use 3D models that link subsurface and surface data from the start.

- Proactive risk management: Identify and mitigate risks before they derail the project.

- Faster delivery: Reduce rework and delays by improving communication and coordination.

- Stronger resilience: Design with the full picture in mind, for better long-term outcomes.

And it all works because the tools are purpose-built. Civil and geotechnical work is too complex for generic solutions. Engineers need software that can simulate conditions, analyze slope stability and deformation, and manage large volumes of data all while supporting collaboration.

Just as important is the ability to work with connected data. A common digital environment unifies geotechnical, geological, and design data, ensuring every stakeholder, from geologists and geotechnical engineers to civil designers and construction managers, is working from the most accurate and current information.

Change is certain. So is our agility.

Transportation projects don’t move in straight lines. Conditions change. Priorities shift. Regulations evolve. Teams rotate. Staying on track requires constant adaptability.

You can’t predict everything, but you can be ready. That’s why centralized, digital workflows are essential. A connected platform allows geotechnical and civil teams to align seamlessly as new data is collected in the field. Models can be updated instantly. Insights are shared immediately.

This adaptability doesn’t end with design. Subsurface understanding captured early continues to add value during operations and maintenance. Whether planning a repair, responding to a weather event, or monitoring for ground movement, teams can rely on a digital foundation that’s still relevant years after construction.

And when unexpected changes do occur, digital workflows and scenario modeling let teams respond quickly. Engineers can simulate the effects of different ground conditions or scope adjustments and keep the project moving forward with confidence.

Real-world impact

Across the world, transportation agencies and engineering firms are seeing what’s possible with a connected, subsurface-first approach.

- Efficient design documentation: Arcadis leveraged OpenGround to establish a single source of truth for ground data across their projects, providing access to both internal and external teams globally, streamlining efficient design documentation and profile production.

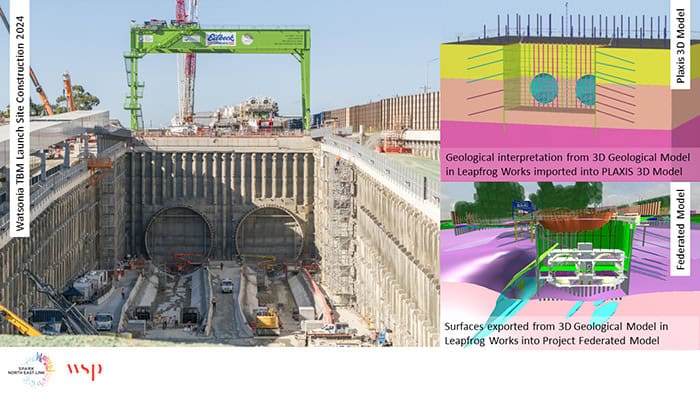

- Reliable cut and fill estimates: In Australia, WSP Spark NEL used Leapfrog Works to divert more than 1 million cubic meters of material from waste, saving AUD 10 million on a road project by reusing site materials.

- Effective management of aging infrastructure: Tecne Systra-SWS utilized OpenTunnel in conjunction with engineering geology from Leapfrog Works and analysis in PLAXIS to increase productivity in geotechnical analysis by 80%, leading to better management and rehabilitation of Italian tunnels, increasing their safety and lifespan.

- Managing vast amounts of subsurface data: In the U.K., the Lower Thames Crossing JV used OpenGround to capture, manage, and share vast amounts of site investigation data in real time, streamlining decision-making and increasing transparency.

- Understanding and communicating geoscience uncertainty: For Transport for London, Arup built a geological model of Crossrail 2 using Leapfrog, helping them communicate complex ground uncertainty to stakeholders and inform design decisions.

- Safety and reliability of geotechnical structures: WSP used PLAXIS to analyze 160 axisymmetric models for a complex road project, automating analysis and graph plotting for easy interpretation of results, highlighting the efficiency of integrated tools.

These aren’t just technical wins, they’re outcomes that improve project delivery, reduce costs, and increase resiliency.

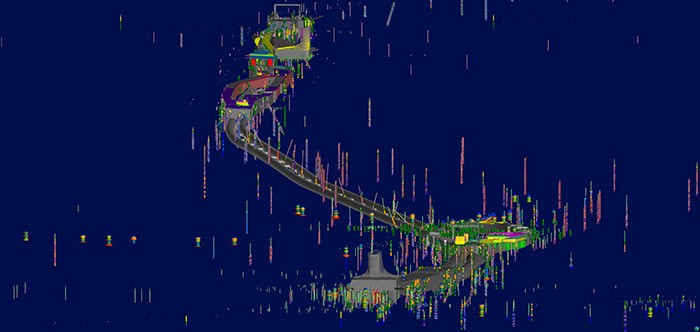

Watsonia TBM launch structure. Image courtesy of Spark and WSP.

Watsonia TBM launch structure. Image courtesy of Spark and WSP. 3D Geological Leapfrog Model. Image courtesy of Spark and WSP.

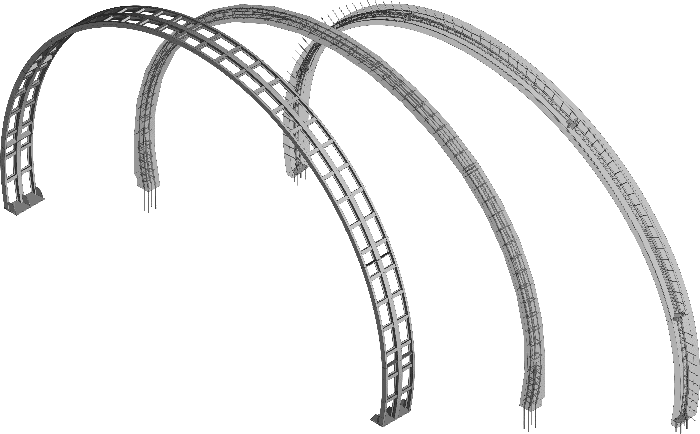

3D Geological Leapfrog Model. Image courtesy of Spark and WSP. Steel mesh reinforcements. Image Courtesy of Tecne Systra.

Steel mesh reinforcements. Image Courtesy of Tecne Systra.Building resilience from the ground up

In an era of climate uncertainty, population growth, and strained infrastructure budgets, building resilient transportation systems is more critical than ever. But resilience isn’t just about stronger materials or smarter alignments. It’s about knowing what’s below and building with that knowledge from the beginning.

By connecting subsurface understanding with design and delivery, we’re not just avoiding risks. We’re creating infrastructure that lasts longer, adapts better, and delivers greater value over its entire lifecycle. So next time you think of a foundation, don’t stop at the concrete slab. Think of the layers beneath. Because real engineering excellence starts below the surface.

To learn more, please visit https://www.bentley.com/software/geotechnical-engineering/.