This article is based on a report published by Bentley in June 2025. To access the full report, use the link at the bottom of the article.

How digital twins improve infrastructure outcomes

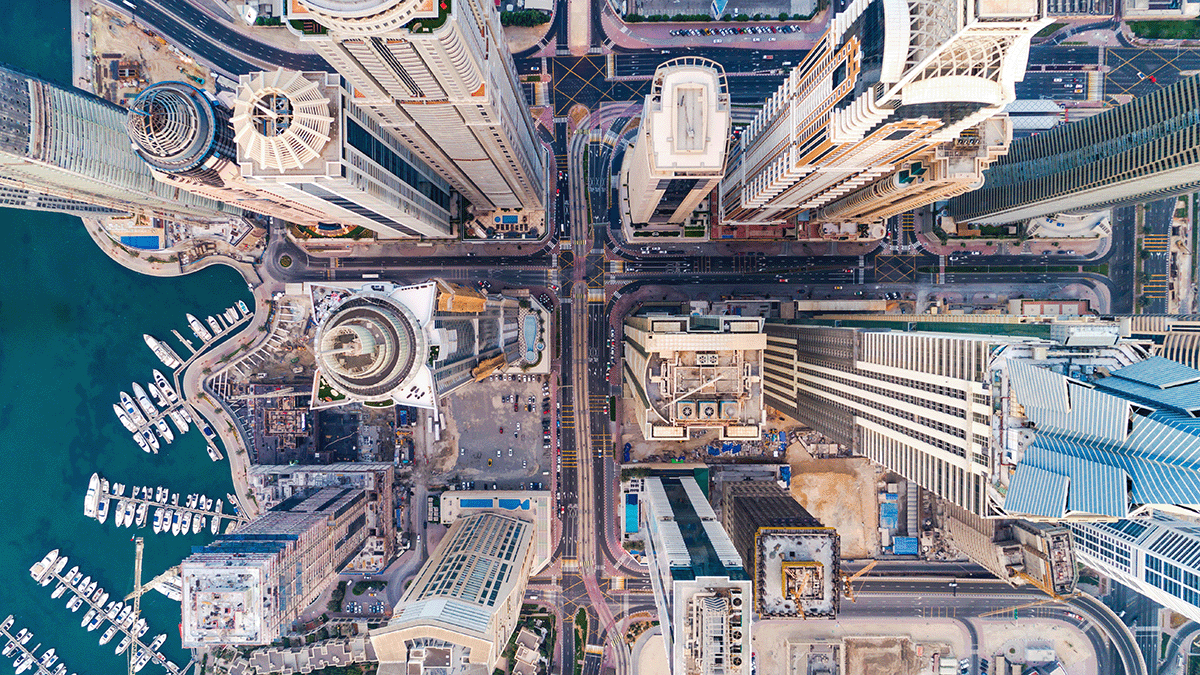

Digital twins have redefined what’s possible in infrastructure. Infrastructure professionals are using them to boost efficiency, reduce risk, lower carbon emissions, and optimize asset performance. By combining and leveraging data from various sources, including 3D models, geospatial context, Internet of Things (IoT) sensors, operational records, and more, digital twins deliver new levels of situational awareness for responding to current conditions and planning for the future.

Technology advances have made digital twins accessible, scalable, and cost-effective. A Bentley survey found that over half of infrastructure professionals already use digital twins in some projects, and KPMG ranks them among the top 10 trends shaping infrastructure. How are digital twins actually being used in infrastructure projects today? This blog will show examples of how they are implemented at every stage of the infrastructure lifecycle.

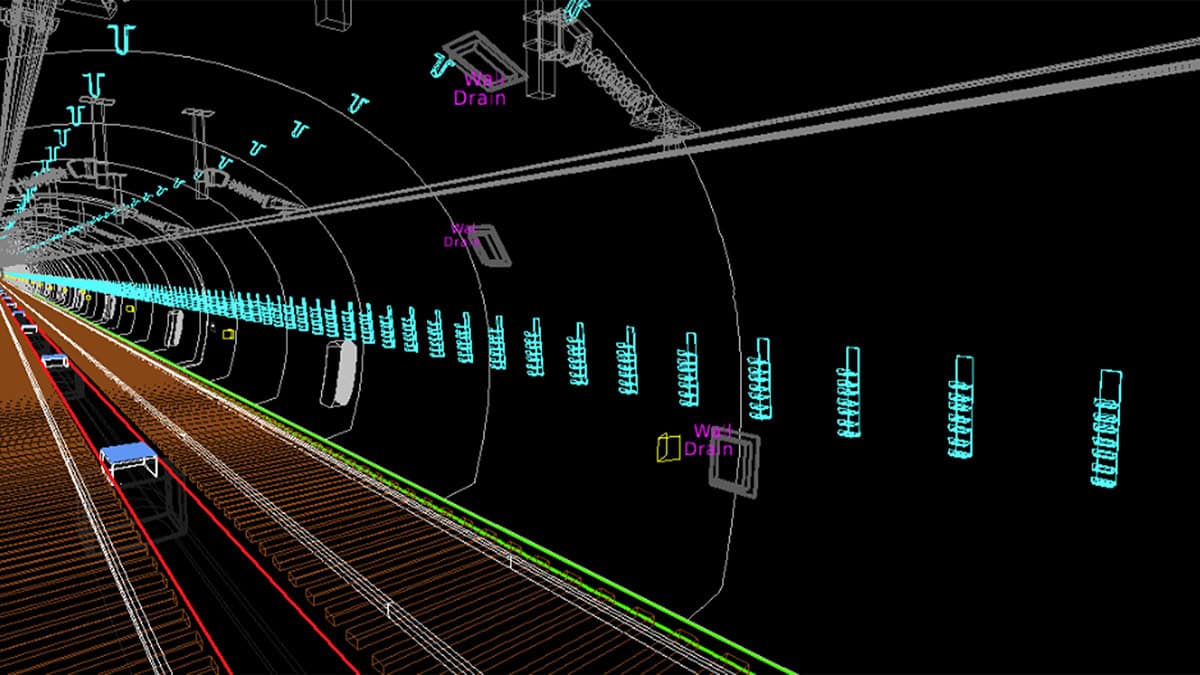

Design: Enhancing accuracy and stakeholder collaboration

Digital twins enable engineers, architects, and stakeholders to rapidly explore a design’s constructability, resilience, and sustainability. Teams can simulate how an asset will interact with the existing terrain, infrastructure, and environmental factors, as well as resolve design clashes and scheduling issues before breaking ground.

Common design challenges that can be addressed with digital twins include:

- Designing for real-world conditions

- Gathering stakeholder input

- Ensuring compatibility across tool sets

- Validating designs and constructability

Case study: Designing for real-world conditions— I-95 Rappahannock River Crossing

For the Virginia Department of Transportation, successfully upgrading one of its most congested corridors—the span of Interstate Highway 95 crossing the Rappahannock River in Northern Virginia—meant ensuring the design could stand up to complex on-the-ground realities. The project included creating six miles of new southbound lanes, converting the original lanes into a collector-distributor road, and constructing four new bridges over the Rappahannock River.

To support this work, the lead designer, Johnson, Mirmiran & Thompson, developed an infrastructure digital twin to model the roadway, bridges, and terrain with a high level of accuracy. Project teams and stakeholders could easily view models of the new roadways and bridges in their geospatial context, enabling them to evaluate the design’s impact on traffic flow, safety, and sustainability early in the process as well as identify potential issues before they became costly delays.

Additionally, the team could give decision-makers at 10 federal and local regulatory agencies a clear view of how the design addressed environmental and operational concerns. This helped navigate complex environmental sensitivities and requirements while ensuring that the project met its timeline and performance goals.

Construction: Reducing risk and improving scheduling

Digital twins unify and visualize asset specifications and site conditions with scheduling, cost, compliance, and environmental data to enable teams to rehearse the construction sequence and logistics before breaking ground. Teams can access up-to-date engineering data from any location—ensuring alignment with the latest designs, schedules, and specifications.

Common construction phase challenges include:

- Managing risks in safety, logistics, and scheduling

- Accessing high-quality engineering data in the field

- Tracking and optimizing complex resources

- Enabling accurate as-built documentation and recordkeeping

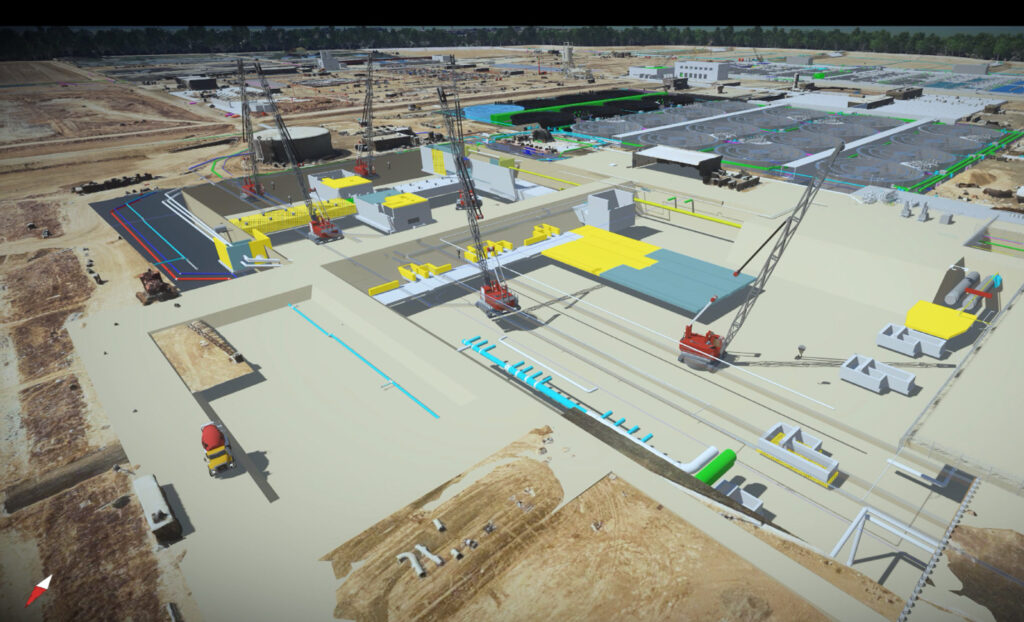

Case study: Tracking and optimizing complex resources—The EchoWater Project

Tracking and optimizing complex resources across 22 projects, many occurring simultaneously, on an active wastewater treatment facility is a tall order. For the Sacramento Area Sewer District, the EchoWater Project represented not only one of the largest public-works programs in the region’s history, but also one of its most complex—spanning over 100,000 construction activities and involving dozens of stakeholders across a decade.

To manage the complexity and scale of the program, digital construction planning specialist Project Controls Cubed built a federated digital twin that brought together design models, construction schedules, and cost data into a single, continuously updated environment. The digital twin served as the foundation for planning, coordination, and decision-making, providing real-time visibility into progress, resource allocation, and complex construction sequences across multiple projects.

Stakeholders used the digital twin to rehearse shutdowns, assess access constraints, and identify schedule risks in advance, which helped them avoid costly conflicts and enabled smooth execution across interconnected projects. With multiple projects unfolding in parallel, they were able to develop a detailed digital program schedule linked with resource and cost information that could be monitored in real time, tracking and reporting progress and financial status.

The entire program was delivered on time and USD 400 million under budget.

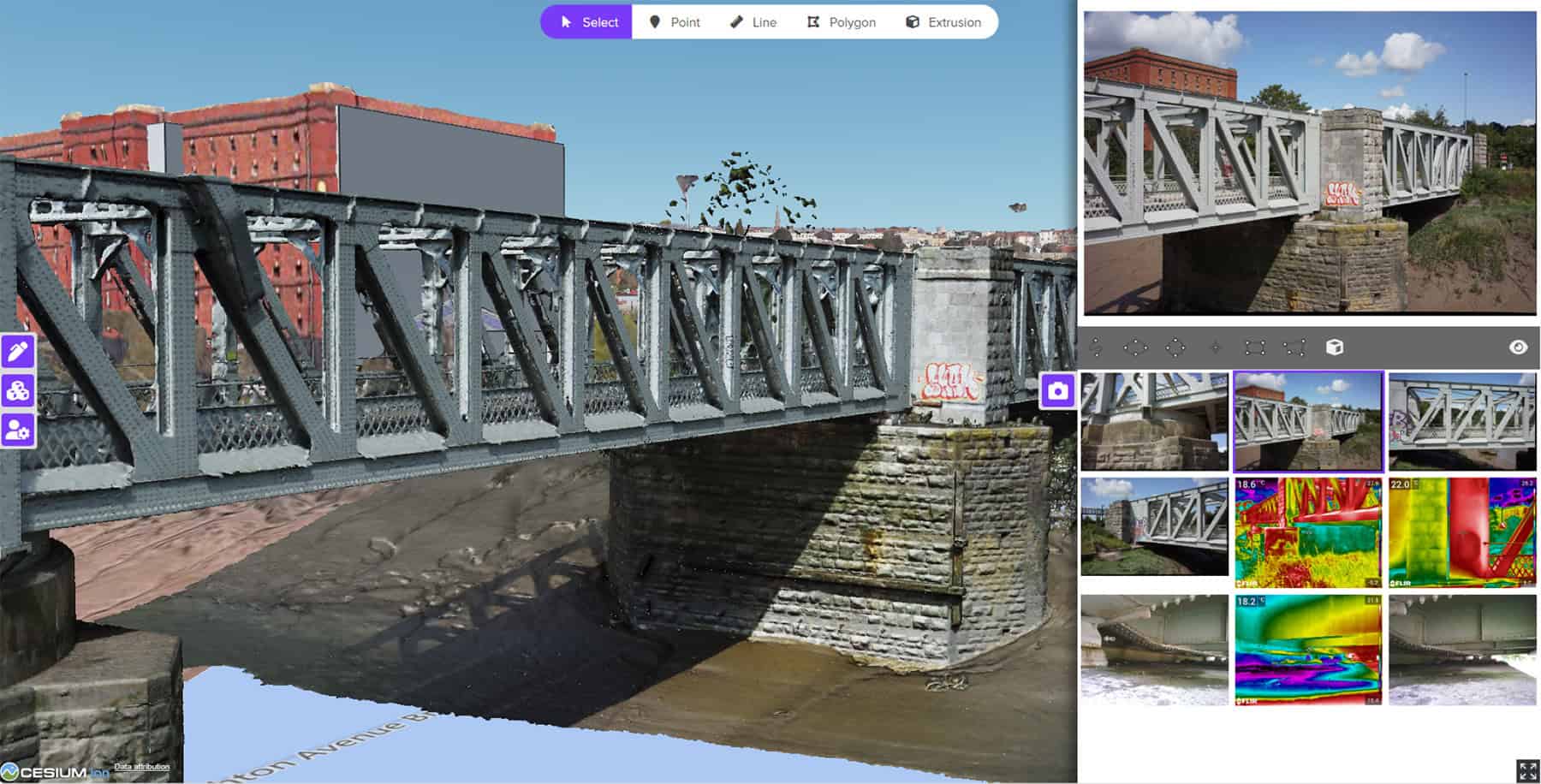

Operations: Improving reliability and predictive maintenance

As assets age, the risks of service disruptions, safety incidents, and escalating maintenance and insurance costs also increase. Yet the information needed to mitigate these risks—engineering design files, asset records, sensor data, maintenance logs, and inspection reports—is often spread across disconnected systems and incompatible formats. Digital twins can address this by unifying asset information into a single comprehensive and federated view. If conditions shift suddenly, they can respond by alerting personnel and visualizing anomalies to help avoid costly downtime and disruptions.

Common operations phase challenges include:

- Minimizing disruptions when breakdowns occur

- Responding quickly to potential operational disruptions

- Maintaining safety and sustainable operations

- Planning and scheduling maintenance with incomplete or inaccurate data

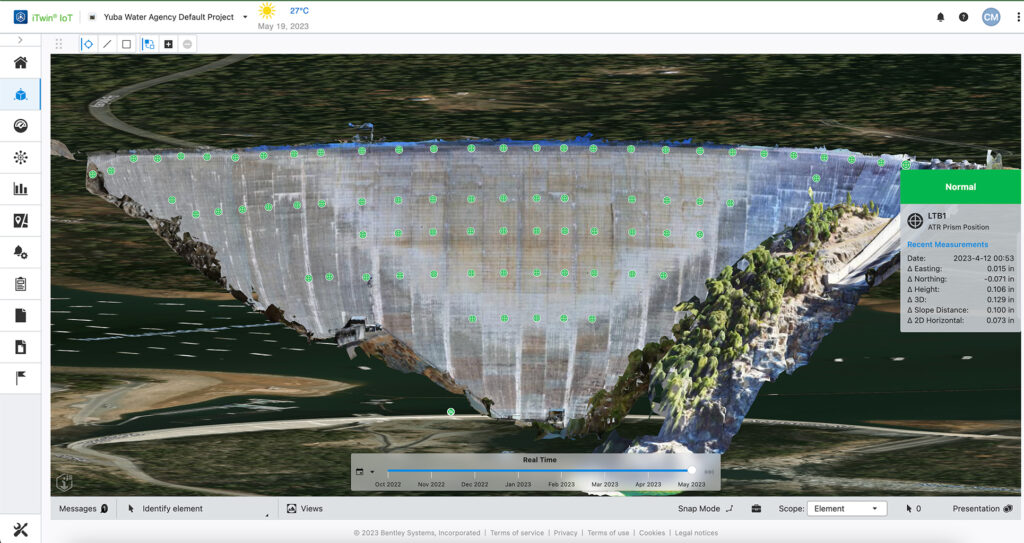

Case study: Maintaining safety and sustainable operations—New Bullards Bar Dam

Owned and operated by Yuba Water Agency, New Bullards Bar Dam is a 645-foot-tall concrete arch dam. Built in 1970, it is California’s second tallest and the fifth tallest in the United States.

The dam’s legacy monitoring system required time-consuming, costly, and hazardous manual data collection that enabled analysis of only a portion of the dam. To maintain safety and sustainable operations, Yuba Water launched a project to modernize the monitoring system.

Using a digital twin, the team can now visualize and track structural movement over time as the dam is exposed to environmental stress. Today, the system collects data twice daily from more than 80 sensors monitoring water levels, temperature shifts, and hydrological and seismic activity. According to Yuba Water, the system delivers 1,000 times more data points per week than the manual process did—accelerating issue detection and enhancing risk assessment and dam safety.

The future of digital twins: AI-powered scenario planning and insights

Imagine that a design team needs to evaluate the location for a new project. With an AI-powered digital twin of the site location, the team uses natural language to test a series of “what if” scenarios. “What if the site experiences a 100-year flood—or a flood followed by an earthquake? What if we shift the highway alignment to avoid underground utilities?”

This isn’t purely speculative. What’s next is not a matter of technological innovation, but really a matter of integrating existing advanced technologies. AI-powered digital twins will redefine how the next generation of infrastructure professionals will work. Project managers will ask natural-language questions and receive answers based on the twin’s historical, geospatial, structural, and operational data—as well as data from past projects.

Conclusion: Digital twins are transforming infrastructure today

As the examples cited above demonstrate, digital twins are addressing infrastructure challenges at every stage of the asset lifecycle. The interoperability of digital twins will continue to develop and ensure that valuable data remains intact and additive as assets transition from one phase to another. The addition of artificial intelligence that understands the context and logic of infrastructure engineering will help teams design, build, and operate more efficiently and gain situational awareness to plan for the future.

See more examples of infrastructure leaders improving project outcomes with digital twins.