As I travel both across the U.S. and internationally, I see massive infrastructure projects underway at almost every airport that I pass through. These projects include new and expanded terminals, updating aging infrastructure, integration of IoT sensors and improving passenger movement, as well as sustainability initiatives such as electrification of the airport and conversion to greener materials and fuels. All these projects align, in one way or another, with industry drivers to improve passenger experience, increase operational capacity and efficiency as well as creating greener and more resilient airports.

For this blog, we will focus on how the entire infrastructure lifecycle can and does impact passenger experience, as well as provide real-world examples of how major airports around the globe are improving passenger experience from design to maintenance.

Smarter airport layout design with digital twins

The Guangzhou Baiyun International Airport is a great example of leveraging digital solutions for a more efficient design process. With Bentley OpenRoads Designer, they were able to streamline the drawing process, cut down on construction changes, and try some new forward design techniques. These tactics helped boost productivity by over 15% and reduced common design errors by 2%. Then, as they got ready for construction, they took things a step further by refining the design model and using Bentley View (formerly Navigator) to tackle the tricky issue of coordinating across different disciplines, especially in track engineering. That move really paid off, improving project quality, lowering costs, and making the worksite more efficient, which led to a 25% jump in construction efficiency.

The design phase for infrastructure projects is not only where everything begins, but where the foundation for success is laid. It’s not just about blueprints and technical specs; it’s about creating a vision that ensures smooth execution, cost efficiency, and a great experience for the passengers who will ultimately use the space.

One of the biggest game-changers in modern design is collaborative engineering. By making sure that everyone on the team is working from the most up-to-date information, we can catch potential issues early when they’re easiest and cheapest to fix. Waiting until later in the project to address design flaws can cause costs to skyrocket and timelines to slip. Early collaboration helps avoid that.

But it’s not just about efficiency. Thoughtful design also plays a huge role in shaping the passenger experience. From intuitive layouts to smooth traffic flow, every detail matters. Designing with the end user in mind means creating spaces that are not only functional but also enjoyable to move through.

To make sure that our designs hold up under real-world conditions, we turn to simulation. By modeling different passenger volumes and even emergency situations, we can stress-test our plans before a single brick is laid. This kind of foresight directly impacts safety, comfort, and overall satisfaction.

And thanks with to tools like virtual and augmented reality, we can now walk through our designs before they’re built. These immersive experiences help stakeholders visualize the final product, spot potential issues, and make more informed decisions.

4D construction modeling for complex airport infrastructure

To tackle the complexities of building the world’s longest elevated pedestrian walkway at the Seattle-Tacoma International Airport, Clark turned to Bentley’s SYNCHRO 4D and reality modeling technology. By linking their construction schedule directly to a 3D digital model, they created a fully visualized construction digital twin, a powerful tool that let them simulate every step of the build before it happened.

The simulations helped the team plan how to move the massive bridge span from a remote prefabrication site, down active taxiways and runways, and into place without disrupting airport traffic or parked aircraft. After multiple digital iterations, they executed the move on a rainy night with precision, achieving final placement within just three-eighths of an inch.

Beyond construction, Clark also delivered a data-rich BIM model with 18 standard attributes per asset, meeting the Port of Seattle’s requirements for long-term facilities management. By integrating digital tools from the start, they ensured a seamless transition from construction to operations.

This project didn’t just break records, it set a new standard for how digital technology can transform airport construction, making it safer, smarter, and more efficient.

Looking back at the Guangzhou Baiyun International Airport, the team didn’t rely on traditional methods when it came to building one of the most complex airport road projects in the country. Instead, the Guangzhou Baiyun International Airport didn’t rely on traditional methods; they embraced cutting-edge technology to get the job done smarter and faster.

During the construction phase, the team turned to Bentley’s SYNCHRO 4D software to run detailed rehearsals for some of the trickiest parts of the build, including complex nodes and uniquely shaped sections. These virtual simulations helped them fine-tune technical solutions and streamline the construction process before even breaking ground.

The project’s building information modeling (BIM) reached a level of detail and precision that set a new benchmark nationally. The model wasn’t just a 3D representation; it was packed with rich data, including material specs, construction parameters, and experimental results. In total, the digital model included over 3 million components, creating a massive dataset that powered smarter decision-making throughout the project.

With this digital-first approach, the team achieved something remarkable: zero demolition or rework. Everything was built right the first time.

Airport construction is a high- stakes balancing act. You’re not just building complex infrastructure; you’re doing it in a live environment where thousands of passengers come and go every day. That’s why more construction teams are turning to smart software to get the job done right.

These digital solutions help construction firms and airport operators stay on schedule, reduce disruptions, and keep everything running smoothly, even during major upgrades or expansions.

By leveraging construction simulation and scheduling tools, teams can visualize exactly how a project will unfold over time. It’s like watching your construction plan come to life before the first shovel hits the ground. This proactive approach helps identify risks early, optimize sequencing, and avoid costly delays.

But it doesn’t stop there.

By combining digital models with real-time performance tracking, both field crews and office teams can make fast, data-driven decisions. Whether it’s adjusting timelines, reallocating resources, or resolving issues on the fly, everyone stays aligned and informed.

How digital twins enable efficient airport utility and asset management

To keep track of its ever-changing facilities, Sydney’s airport design team turned to Bentley’s iTwin Experience as their go-to GIS platform. This wasn’t just about drawing maps; it was about building a smart, data-rich foundation to manage their airport infrastructure.

Using advanced GIS and 3D modeling capabilities, the team created intelligent digital representations of the airport’s assets, from terminals and car parks to every single door and tenancy. And we’re talking about a lot of doors—over 8,500 in the international terminal alone! Each one was assigned a unique ID, making it easy to locate and manage, whether for maintenance, security, or access control.

The result? A fully integrated, map-based digital twin that allows airport staff to find any asset, like a specific door or utility line, instantly and accurately, right from the web. No more guesswork, no more outdated spreadsheets.

But the benefits go far beyond asset tracking. By working in a collaborative digital environment powered by Bentley ProjectWise, and using tools like MicroStation, Bentley Map Mobile, and NavigatorBentley View, the airport team has streamlined workflows, improved data consistency, and saved serious time and money.

Here’s what that looks like in numbers:

• Over 1,800+ hours saved annually on airspace registrations

• 1,000 hours saved through improved mobile workflows

• Thematic maps that used to take days now take minutes

• 12,395 hours saved per year overall—the equivalent of nearly seven7 full-time staff

And with self-service portals, stakeholders can now access the information that they need without relying on manual requests, cutting down on paper use and administrative overhead.

By turning their infrastructure into a single source of truth, Sydney Airport has not only improved day-to-day operations, but also laid the groundwork for smarter, more scalable airport management in the future.

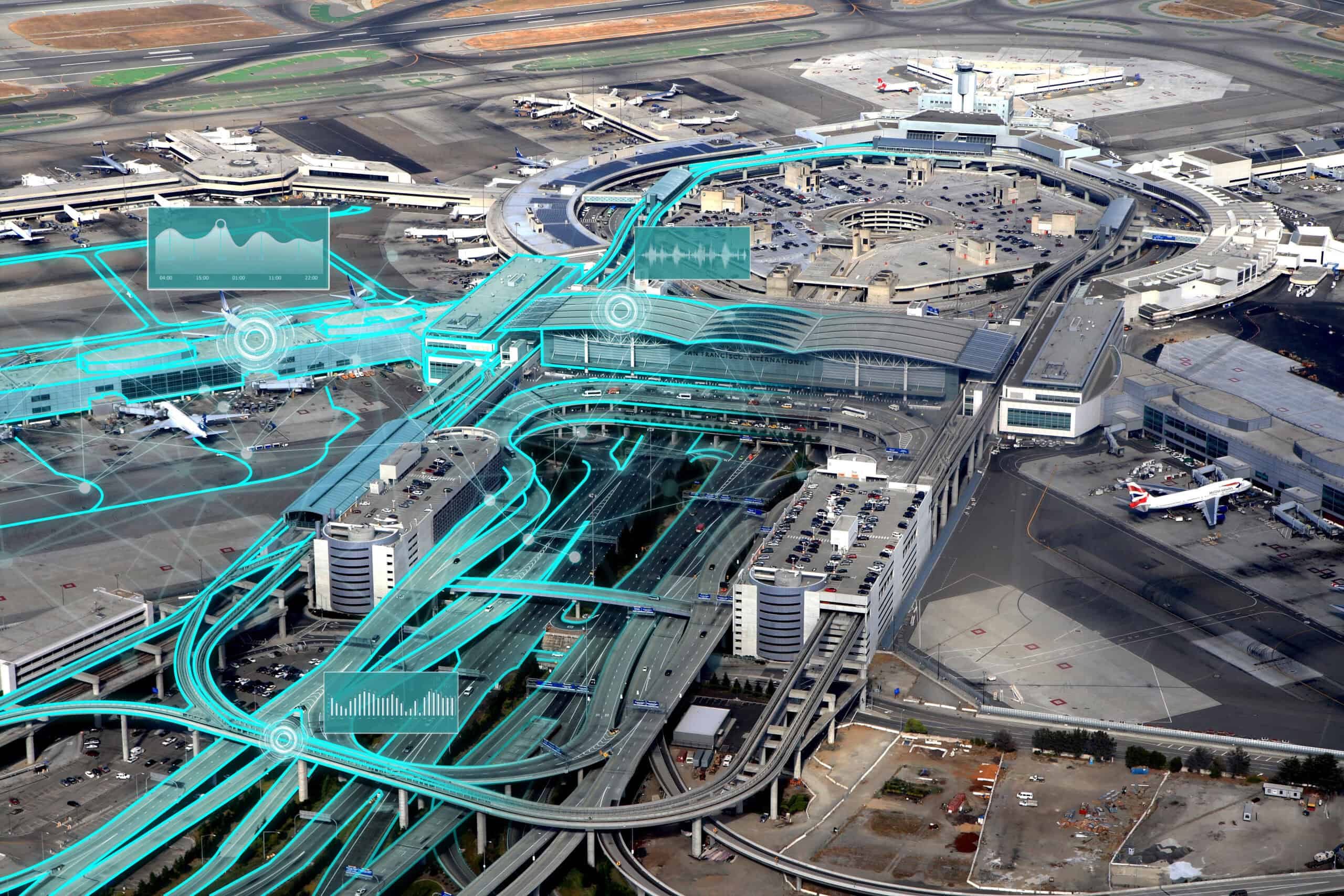

Airports are like small cities—constantly evolving, incredibly complex, and always on the move. Managing them efficiently takes more than just people and processes; it takes powerful, connected technology.

That’s where digital twins come in.

By feeding real-time data from design and construction into Bentley’s digital twin platform, airports can maintain a living, up-to-date digital replica of their physical environment. This “evergreen” model becomes a central hub for decision-making, allowing operators to overlay operational data, like passenger flow, maintenance schedules, or security alerts, right onto the digital twin.

The result is a clearer, more complete picture of what’s happening across the airport at any given moment.

Instead of juggling siloed systems and disconnected data, airport teams can now work with information in context. They can see how everything fits together, from terminal layouts to baggage handling systems, and make smarter, faster decisions that improve efficiency, safety, and the passenger experience.

AI and digital twins revolutionizing airport maintenance

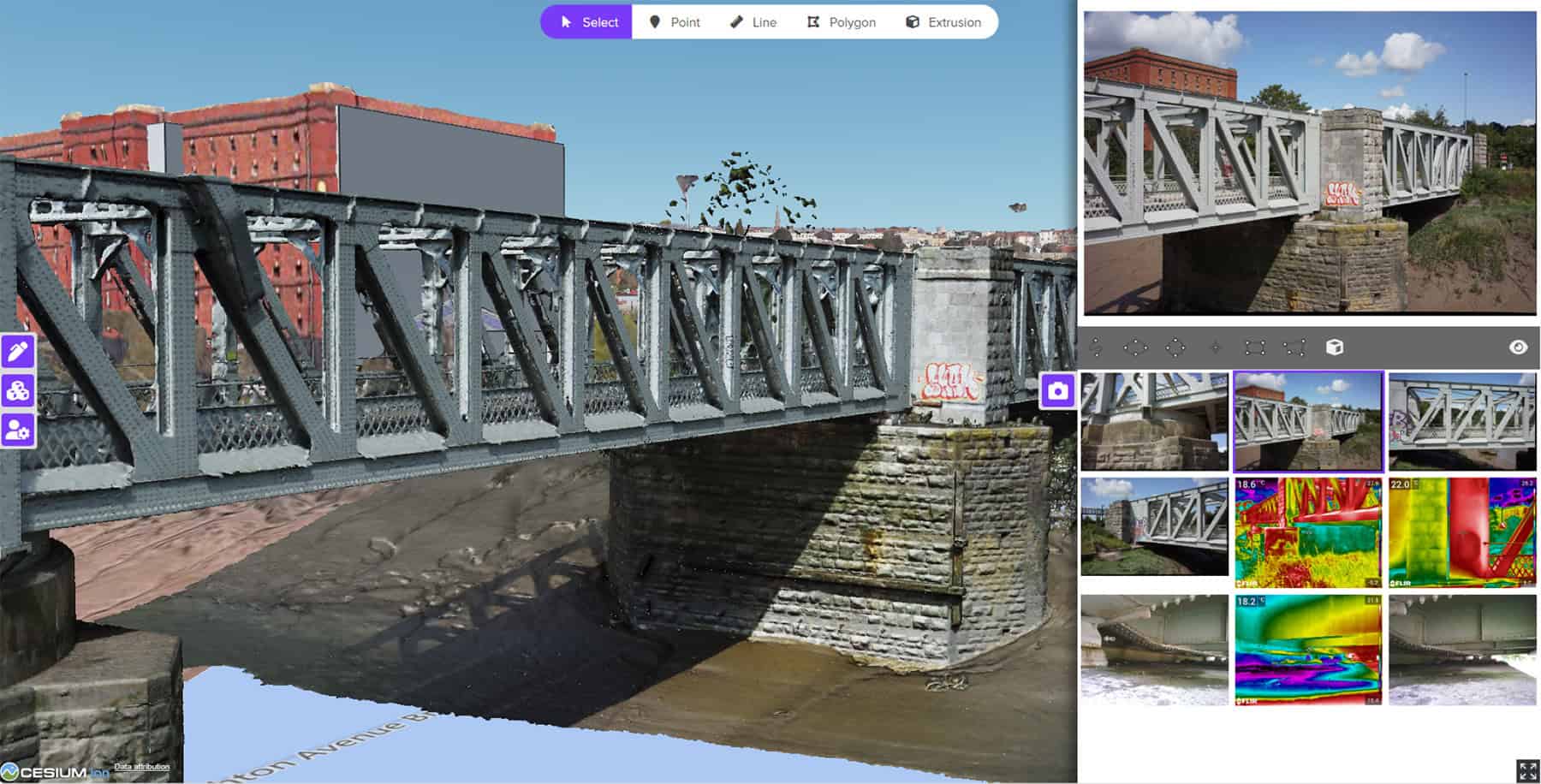

Imagine cutting 75% of your manual fieldwork with the help of technology. That’s exactly what Benesch is doing by embracing the power of AI, machine learning, and infrastructure digital twins.

In a move to modernize pavement management, Benesch piloted a cutting-edge digital solution using Bentley Infrastructure Cloud and iTwin® applications. Their goal was to create a smarter, more automated workflow for detecting pavement cracks, and the results have been nothing short of game changing.

By integrating Bentley’s AI and machine learning into their process, Benesch drastically reduced the need for manual data collection, in fact, they’ve slashed on-site work by a whopping 75%. And the savings don’t stop there. When scaled to future projects, like inspecting 100 airports, Benesch estimates this approach could save around USD 144,000. That’s a serious return on innovation.

But perhaps the most impressive part? Their new data-centric workflow is expected to cut down the time CAD users spend digitizing linework by 99%. That means more time for analysis, planning, and decision-making and less time spent on repetitive tasks.

Benesch’s forward-thinking approach is a powerful example of how digital transformation isn’t just a buzzword, it’s a real, tangible advantage in the world of infrastructure.

Maintenance is no longer just about fixing things when they break; it’s about keeping infrastructure performing at its best, all the time. With powerful digital solutions like predictive and preventive maintenance tools, organizations are streamlining their workflows and shifting toward a more proactive approach. That means fewer surprises, faster response times, and better long-term performance.

One of the biggest game-changers was having instant access to asset information right in the field. Whether it’s a bridge, runway, or transit system, maintenance crews can now make informed decisions on the spot with no more digging through paperwork or waiting on updates.

These tools don’t just boost efficiency, they also enhance safety. By minimizing the time workers need to spend in the field, teams can reduce exposure to hazards and keep both staff and the public safer. In short, software is helping infrastructure operators do more with less: less time, less risk, and less guesswork.

Putting passengers first

At the end of the day, all of this innovation–whether it’s smarter design, streamlined construction, connected operations, or proactive maintenance–comes down to one thing: creating a better experience for passengers. With Bentley’s software solutions, airports are becoming more efficient, more resilient, and more responsive to the needs of travelers. From smoother check-ins and faster security lines to safer, more comfortable terminals, the impact of digital transformation is felt in every step of the journey. As airports continue to grow and evolve, these technologies ensure that passengers aren’t just moving through infrastructure; they’re moving through thoughtfully designed, intelligently managed spaces built with their experience in mind.