With staggering results, Serelle Corn and Jeff Campbell are reshaping how billion-dollar infrastructure gets planned and delivered. And it all started with an office printer and a love story that’s pure Hollywood rom-com.

These days, billion-dollar infrastructure projects are the norm for the married founders of Project Controls Cubed (PC3). But that wasn’t the case 15 years ago, when they tackled a similar project—on their own dime—just to get a seat at the table.

At the time, Serelle Corn and Jeff Campbell were still trying to convince the infrastructure sector to believe in something that, to them, was self-evident: that digital design and construction planning tools, and digital twins of critical infrastructure, could boost collaboration, slash waste, and make the impossible possible. The pair knew that the technology could deliver airports, massive water treatment plants, and other projects on time and millions of dollars under budget.

Once upon a time near Hollywood

Serelle Corn and Jeff Campbell, founders of Project Controls Cubed (PC3).

Serelle Corn and Jeff Campbell, founders of Project Controls Cubed (PC3).Theirs is a partnership with more than its share of Hollywood moments, right down to how they met. It all started in 2006, when Corn—already forging a career in architecture—was working in a shared office where Campbell, a construction scheduler, happened to sit next to the printer. “He was so good-looking, I kept printing my emails. Who prints emails?! And I’d dress super cute,” she recalls.

The feelings intensified when Campbell rescued an abandoned puppy from a busy road, adopted her, and put her picture on his desk. With Campbell’s hero bona fides firmly established, Corn made her move–and it was decisive. Two weeks later, they moved in together.

While both were working on projects at Los Angeles International Airport, it was Campbell—tasked with scheduling—who felt the full weight of their complexity. “We had thousands of drawings, and tens of thousands of activities, so it was really difficult conveying our plan to the owner, Los Angeles World Airports, and for the contractor to plan, and actually visualize what needed to happen,” Campbell says. Delays at a major airport can ripple across the globe.

Goodbye, Gantt

Traditional planning tools such as Gantt charts and spreadsheets just weren’t cutting it. Campbell knew there had to be a better way—one that could make the schedule as visible and dynamic as the project itself.

After the global financial crash of 2008, Corn suddenly found herself out of work. With her future upended and Campbell increasingly frustrated by the limits of legacy tools, they decided to join forces to build a company they wished already existed. Corn brought architectural design and 3D modeling expertise, while Campbell had deep scheduling know-how. They believed that a small, agile team with the right mindset—and the right tech—could revolutionize how major infrastructure projects were planned, built, and delivered to their owners.

In 2010, PC3 was born, with Bentley Systems’ SYNCHRO software platform at its foundation. SYNCHRO enabled company’s approach known as 5D construction planning. It combines layered 3D design models with schedule (4D) and cost (5D) data and transforms how complex infrastructure can be visualized and broken down to a precise sequence of steps.

The gospel of Jeff and Serelle

The early years were all grit and conviction, self-funded digital models and constant evangelism to an industry that wasn’t quite ready to listen. But then came an opportunity with the potential to change everything.

In 2012, PC3 was invited to join a joint venture led by two of the biggest names in infrastructure—engineering giant HDR and environmental specialists Brown and Caldwell. The consortium was preparing a bid for EchoWater: a $2 billion upgrade of the Sacramento Regional Wastewater Treatment Plant. The biggest undertaking of its kind west of the Mississippi River, EchoWater aimed to overhaul an entire regional wastewater system under tight regulatory deadlines and enormous technical complexity. It would span 22 major projects—many interdependent—and demand an extraordinary level of coordination and foresight.

It was a potential baptism of fire for PC3’s 5D planning. “The head of program management [at Brown and Caldwell], Pervaiz Anwar, had so much insight and vision,” Corn says. “He took the idea of 4D, 5D digital twins and drove it.” Anwar asked PC3 to create a white paper and presentation listing the benefits of their approach, which they duly did. But it wasn’t enough to change hearts and minds at the highest levels. “You tell a client, ‘Hey, we can save you time and money.’ They want to believe it, but they just don’t have enough evidence,” says Corn. “The hardest part is, how do we get them on this train?”

Ingress, egress, progress!

In the end, there was only one answer: If you build it, they will come.

Having tried everything else, the couple took matters into their own hands. In a scene worthy of its own training montage, they worked around the clock, and on their own dime, to create a full 5D model of EchoWater’s largest project: the new Biological Nutrient Removal (BNR) facility. Covering an area of about 18 football fields, it is the heart of the upgraded EchoWater project, designed to remove organic matter, 99% of ammonia, and 89% of nitrogen from wastewater, dramatically improving water quality before it is released into the Sacramento River.

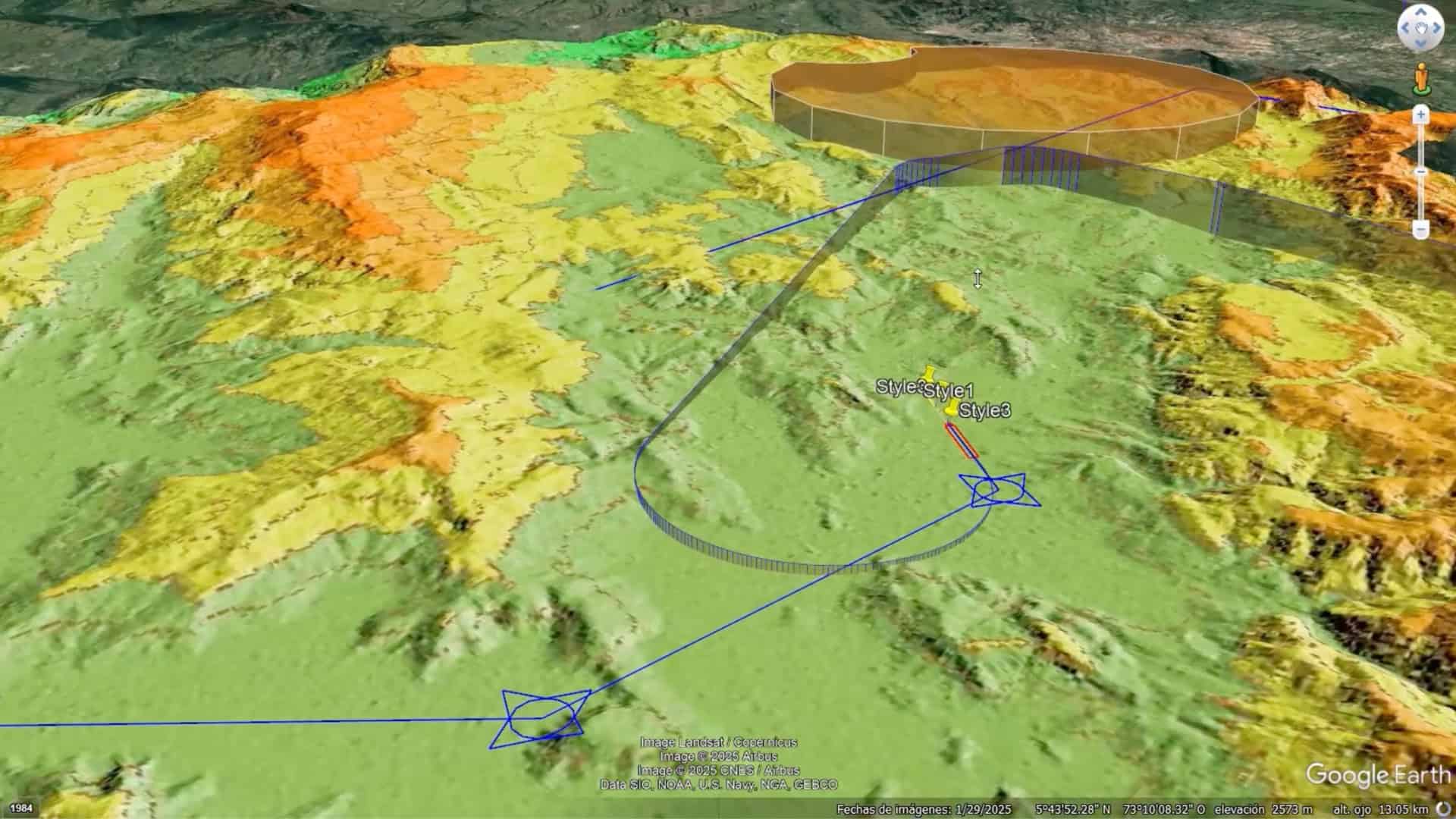

Renderining of the EchoWater project area. Credit: Regional San/Project Controls Cubed

Renderining of the EchoWater project area. Credit: Regional San/Project Controls CubedTo create the 5D model, Corn and Campbell used Bentley’s SYNCHRO to fuse the project’s 3D design with schedule and cost data. Drawing data from contractor Building Information Models (BIM) and schedules, underground utility maps, and regulatory requirements, they built a dynamic simulation of the BNR facility taking shape and the growing cost savings over time. The result: a powerful, visual model that stakeholders could finally relate to.

And, boy, did they relate. The model was basic and pixelated by today’s standards, but its impact was electrifying. “We’d only got 30 seconds into the video, showing how the BNR would take shape as currently designed, and they suddenly said, ‘Uh-oh, we can’t build it this way,’” Campbell recalls. The planned placement of a large, lidded section meant the massive equipment needed to drop in the heavy pipework would have nowhere to sit. Hitting that issue once construction had begun would have been expensive and time-consuming, but the problem wasn’t obvious.

Corn picks up the story: “Straight away, everyone—the project manager, the designer, the owner—started talking about ingress, egress, the lid and the pipes, like ‘We’ll need to come in from this side, and sequence the concrete pours this way.’ And that was just from this video of our model. And we’re just sitting there thinking, ‘My gosh, that’s all it took!’”

Campbell adds, “It was a huge epiphany for everybody. They were like, ‘Oh man, we probably just saved maybe 30 or $40 million.’”

On time, $400 million under budget

Corn and Campbell had broken through. From that moment on, using PC3 for scheduling was mandated across all but one of EchoWater’s overlapping projects. Contractors were now required to submit their own digital twin models and baseline schedules, integrating them into the shared SYNCHRO environment. It meant that everyone—from designers and contractors to owners and regulators—were working from the same playbook, using a federated, dynamic model to coordinate every decision, sequence, and dollar spent.

The only project PC3 didn’t directly manage was the final major piece of the EchoWater jigsaw: the Tertiary Treatment Facility. But even there, the PC3 influence was unmistakable. The contractor hired its own SYNCHRO 4D planner and built a digital twin—essentially running the PC3 playbook. The result? The fewest change orders, the highest profit, and a major reason the entire EchoWater program finished not only on time, but a head-spinning $400 million under budget. In a world where engineering megaprojects coming in on time and under budget is the stuff of fairytales, PC3 helped make one come true.

Green acres

That $400 million helped to create and fund the pioneering Harvest Water project, which aims to replenish the aquifers of California’s Central Valley back to historic levels and support agriculture in one of the most drought-prone regions of the country. And PC3 is still at the heart of it—managing the scheduling to ensure it is in operation as planned by 2027. “It’s a two-for-one,” says Corn. “To finish EchoWater on time and then fund another project that helps heal the land and grow the food that feeds us? That’s what drives us.”

This is no public relations spin. For Corn in particular, water is sacred. Born in Hawaii, she carries a deep cultural responsibility to protect nature. “We say ‘keep it Aloha’—take care of the land, the water, the creatures. That’s what it means to be an Islander, to respect what sustains you. For us, working in water means protecting it—not just for the crops that feed us, but for the oceans, the animals, and the future. It’s all connected.”

EchoWater wasn’t just a success—it was a vindication. Proof that the PC3 model worked, even on the highest-stakes megaprojects. Now, the PC3 team is bringing everything they’ve learned to bear on their new flagship endeavour: the $2.1 billion Bull Run Filtration Project in Portland, Oregon. If EchoWater proved what was possible at scale, Bull Run shows what’s next.

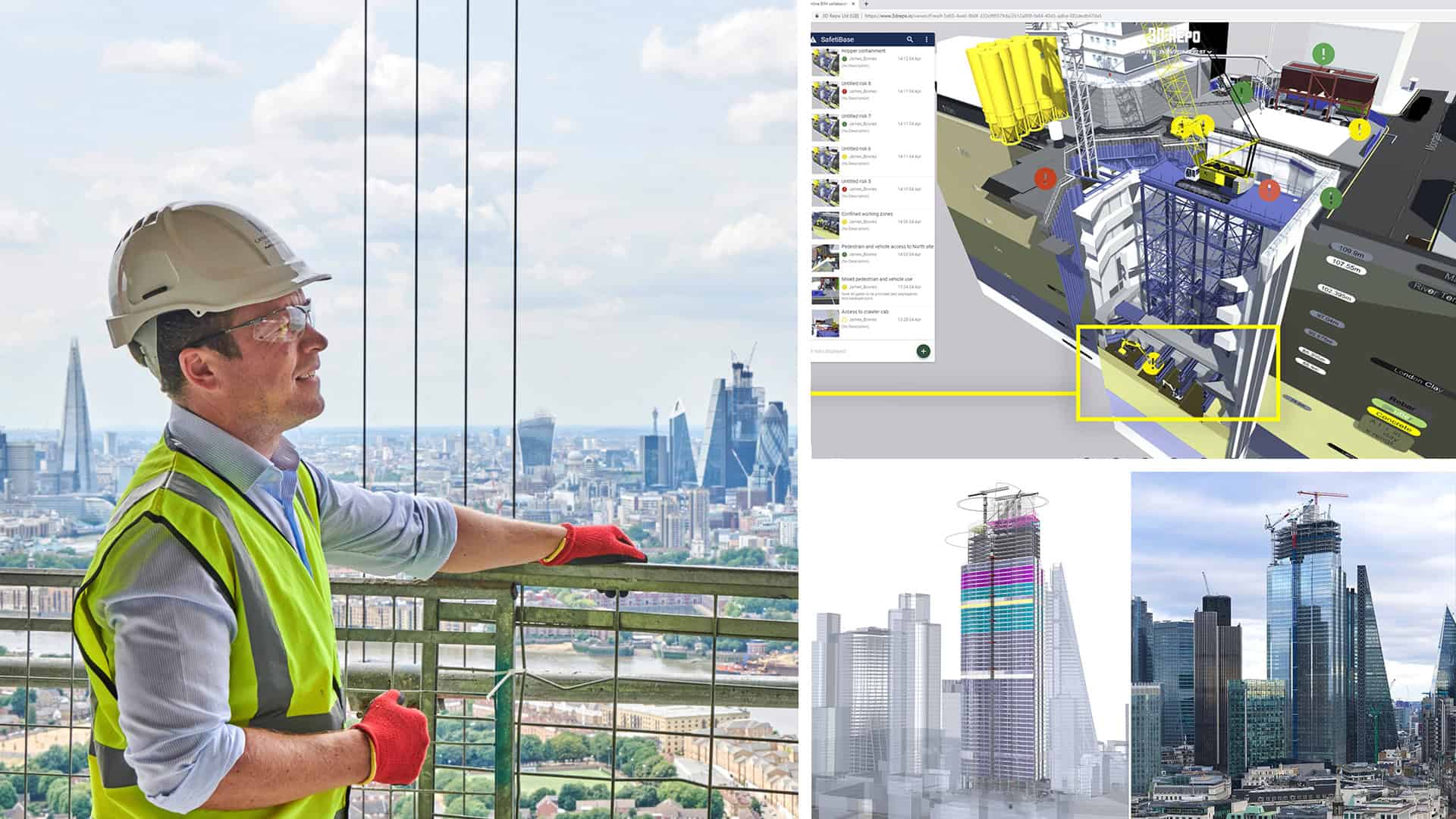

Bull Run Filtration Project in Portland, Oregon includes building pipelines and a filtration facility.

Bull Run Filtration Project in Portland, Oregon includes building pipelines and a filtration facility.The Bull Run project includes building pipelines and a filtration facility designed to filter 135 million gallons of water per day as part of Portland’s efforts to provide high-quality drinking water. The project’s digital twin lives in the cloud, but its portal is a workstation that PC3 installed on site—networked into by contractors, designers, and everyone in between. It’s a quantum leap from the early EchoWater days, when Campbell had to install SYNCHRO viewers one desktop PC at a time. Now, teams access real-time updates and unified project data from anywhere, with a level of situational awareness that was once unthinkable. Bull Run takes collaborative infrastructure planning to the next level—powered by the latest Bentley technology and visualization tools.

“Bentley is the number one, most-called contact in my phone,” Corn admits, a nod to the deep collaboration that underpins PC3’s high-stakes work. From piloting new tools to stress-testing product capabilities in billion-dollar environments, PC3’s relationship with Bentley has become a true co-evolution—technology and practice advancing in tandem.

Getting smarter with AI

Despite managing billions in infrastructure projects, PC3 has just four employees. During EchoWater, it had only three. Their secret weapon? Increasingly automated technology, and the kind of teamwork that only comes from being married to your co-founder. Corn and Campbell share the same office, and during our interview, they often finish each other’s sentences. Their two kids—ages 5 and under—travel the world with them. “We joke that PC3 is our first child,” says Campbell. “And definitely the most demanding.”

PC3 is now turning its focus to the future—not just building better projects, but building smarter systems. With a growing library of as-built data from billion-dollar infrastructure programs, they’re harnessing AI to spot patterns, optimize schedules, and make intelligent suggestions. “AI helps us make smarter plans,” says Campbell. “It learns from all our past projects—actual costs, actual durations, and 3D objects linked to construction activities—and gives us actionable insights, so that when we plan our next major project, we’re not starting from scratch. We can plan with even more confidence.”

Campbell has a vision, and he’s only half-joking. He envisions holograms “of the whole project, live and evolving, hovering over the table.” With cloud-hosted digital twins, high-resolution models, and virtual reality simulations at his fingertips, it’s barely science fiction anymore.

These days, Corn and Campbell don’t just plan infrastructure—they’re rewriting the script for how it gets made. From a printer-side attraction in the office to reshaping billion-dollar building projects , theirs is no ordinary love story. Just two passionate people with a bold idea, a shared mission, and no time to waste. “We’re sleep deprived all the time,” Corn admits, “but we love it. We love what we do. We love our kids. We just … make time for all the most important things.”