If the senior Victorian engineers tasked to dig the Severn Tunnel had truly known what awaited them, they might have opted instead for early retirement. Dug beneath the U.K.’s River Severn estuary between 1873 and 1886, the Severn Tunnel connects the west of England to south Wales. It remains one of Britain’s most audacious engineering projects—and one of the most unforgiving.

The longest underwater tunnel in the world until 1987, the Severn Tunnel has never made life easy. In 1879, with initial excavation nearly complete, disaster struck when a colossal underground spring burst into the tunnel, quickly filling it up. Known as the Great Spring, it took months of pumping and a heroic intervention by diver Alexander Lambert to bring it under control. Using a newly invented rebreather, Lambert ventured hundreds of meters into the flooded tunnel in total darkness to close a sluice door—halting the flood and saving the project.

Even today, 50 million liters of water—enough to fill 20 Olympic-sized swimming pools—must be pumped out daily to keep the tunnel dry.

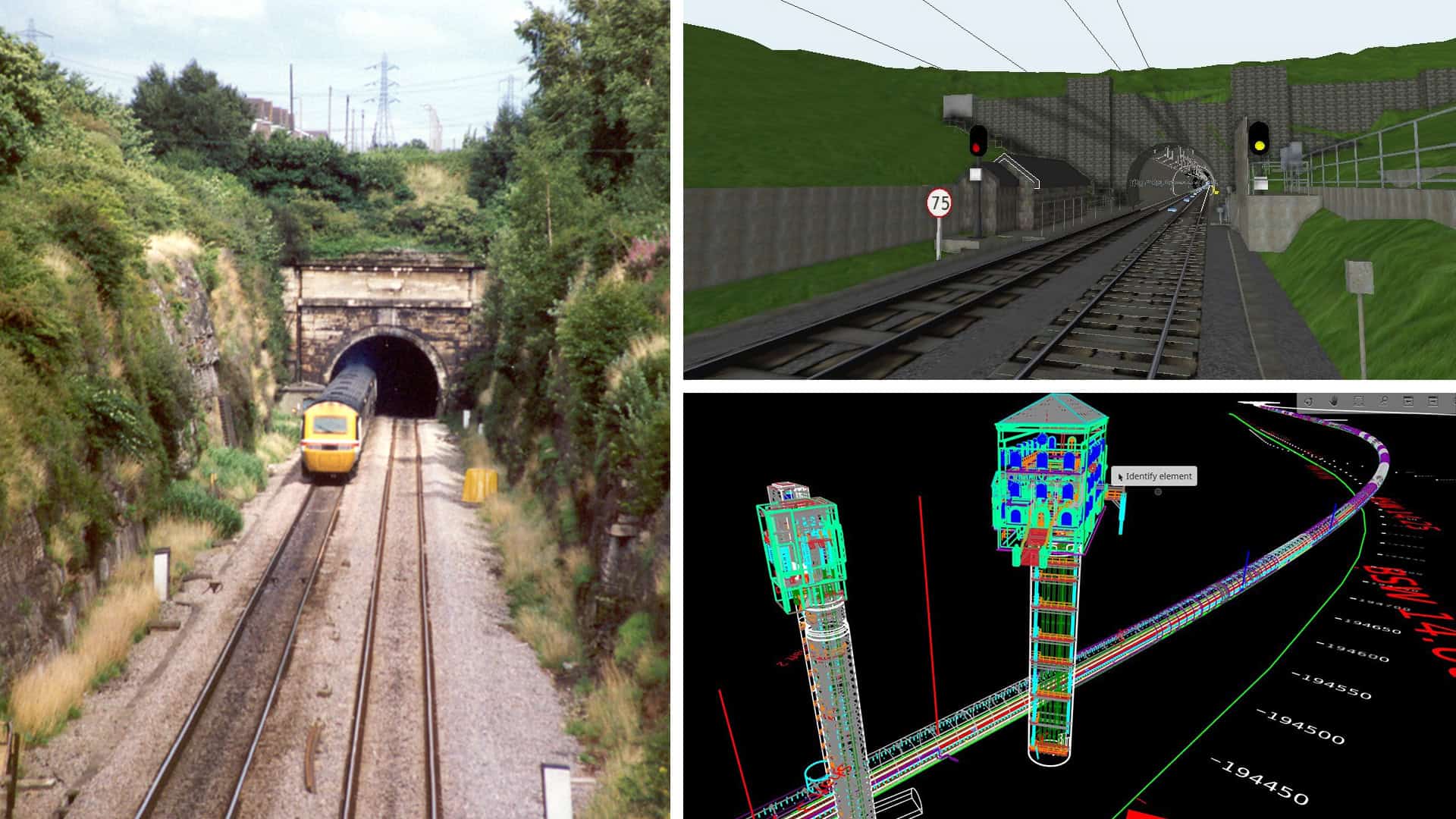

The Severn Tunnel

The Severn TunnelThe tunnel’s corrosive atmosphere—a mix of damp, salt, and fumes—accelerates infrastructure degradation, and particularly metal. For example, tracks that might last 25 years elsewhere often need replacing after less than 10 years in the tunnel. With over 32,000 trains passing through annually, downtime is at a premium.

“To access the tunnel—for maintenance, inspections, or measurements—you have to stop the trains. Simple as that,” says John Nolan of Network Rail, the state-owned U.K. rail company that operates and maintains the tunnel.

It’s a costly constraint—especially in a tunnel as physically punishing as it is technically intricate. The Severn Tunnel is by far the most complex tunnel in Network Rail’s Wales and Western region, according to Nolan. A dense weave of systems runs through its 4.4-mile length: drainage channels, overhead line equipment, electrical infrastructure, signaling, and more. This layered complexity makes the tunnel difficult to inspect, maintain, or even visualize—let alone manage efficiently.

“It’s damp, it’s dirty … there are hazards in there,” Nolan says. “And all you can see is a pinhead of light a couple of miles away. It’s not a place you want to hang around.”

But Nolan is helping shine a broader light inside this marvel of engineering, leading a team that’s building a digital twin of the Severn Tunnel. This richly detailed, data-driven model is already revealing what was once hidden, allowing engineers to explore and analyze the tunnel without stepping inside.

A Tunnel Made Visible

The Severn Tunnel digital twin encompasses 62 key components, from drainage and signaling to overhead line equipment.

The Severn Tunnel digital twin encompasses 62 key components, from drainage and signaling to overhead line equipment.The Severn Tunnel digital twin didn’t begin as a flagship initiative; it started as a missing piece. The rail route’s Paddington-to-Cardiff corridor had already been captured in 3D using aerial and train-borne LiDAR scans during the Great Western Railway electrification project. But the tunnel remained a blank spot. “We always knew access to the tunnel was very poor,” Nolan says. “And because it’s so long, it was always difficult to visualize.” So, Nolan’s small team decided to do it themselves.

They built the model using a layered mix of data, including point-cloud LiDAR scans, train-borne survey results, traditional measurements, and design files for recent track and ballast work. They even incorporated historical engineering drawings from Sir John Hawkshaw—the tunnel’s original chief engineer in the 1870s. The result is a richly detailed “living” digital replica encompassing 62 key components, from drainage and signaling to overhead line equipment and the nearby Sudbrook depot.

The model is hosted in ProjectWise software developed by Bentley Systems, the infrastructure engineering software company. It’s accessible via Bentley’s cloud-based iTwin platform for infrastructure digital twins. As result, the model it’s not confined to high-spec machines or office networks. This level of remote visibility reduces the need to enter hazardous environments and allows engineers, planners, and asset managers to engage with the infrastructure and collaborate from anywhere. “Many people have access now,” says Nolan. “They’re walking around virtually, checking dimensions, clearances, cross sections—everything.”

Looking ahead, Nolan wants to use the digital twin to strengthen emergency response planning. Emergency services already carry out occasional large-scale drills in and around the tunnel, but he plans to create some of these virtually—simulating incidents, such as fires or overhead line failures, within the model. “We’re planning to use the digital twin to storyboard different real-life scenarios,” he says. The aim: to let teams practice, plan, and refine their response without disrupting live operations.

From Static Assets to Smart Systems

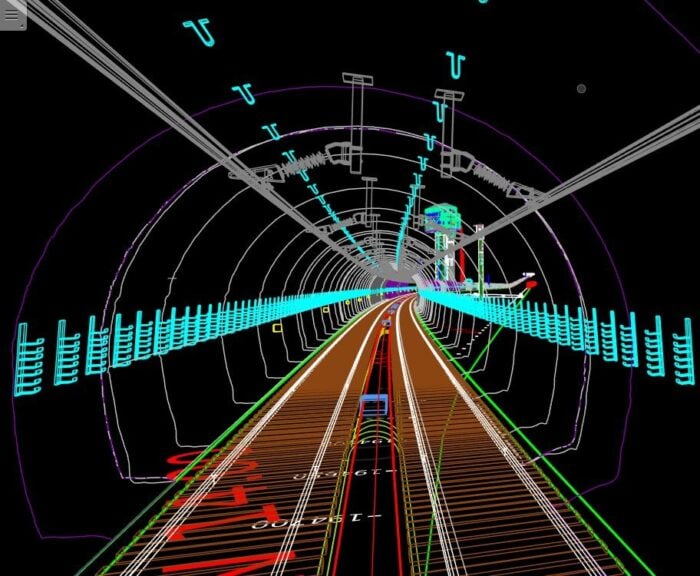

3D digital rendering of the railway tunnel.

3D digital rendering of the railway tunnel.For Network Rail, the digital twin is more than just a visual tool—it’s a foundation for asset intelligence. In Nolan’s rail region, engineers now work within a data environment that connects every asset, streamlining workflows and improving situational awareness.

“In the future, engineers will be able to click on an asset within the model to access key details—age, installation date, maintenance schedule—and track future changes or enhancements,” Nolan says.

The next phase will be to attach intelligent information beyond physical properties. “Performance is the big one,” Nolan says. “Any performance through the railway, performance in the tunnel … we’re going to build that into it.” He also sees potential in using machine learning to identify cracks and fissures from track-scanning data: “Once we have that dataset, we can start identifying issues using AI,” which will lay the groundwork for predictive maintenance and smarter decision-making.

From Digital Twin to Digital Network

This first-of-its-kind project has already attracted global attention. When Nolan shared some details on LinkedIn, reactions poured in from engineers and rail professionals across industries. One heavy construction plant operator, Joe de Caprio, commented: “Having worked in the tunnel numerous times, to see it in this form, it gives a cracking overview.”

The Severn Tunnel digital twin is just the beginning. Nolan’s broader vision is to create high-resolution digital twins for Network Rail’s entire Wales and Western region—2,700 miles of track—built on the same principles of structured data and integrated modeling.

As part of this ongoing work, Network Rail is one of the early testers of Bentley’s upcoming visualization tools, which include integrations with graphics platform Unreal Engine and transform infrastructure models into immersive, interactive experiences. “We’re developing a system where you could start at Paddington, for example, and jump to any station or tunnel—walk the track virtually, explore it in detail,” Nolan says. By combining geospatial data with real-time rendering, Nolan’s team is laying the groundwork for a new era in how rail operators plan, communicate, and deliver their projects.

Just as importantly, Nolan is committed to developing the capability in-house. “We’re recruiting and scaling our own team,” he says. “We’re building the knowledge and capability here at Network Rail. That’s one thing I’m very passionate about.”

A Tunnel Reinvented

Some 150 years ago, the Severn Tunnel began as an audacious Victorian attempt to overcome nature itself—a feat of engineering resilience against water, rock, and gravity. Today, thanks to visionaries like Nolan and Bentley’s cutting-edge technology, this historic tunnel has been rebuilt in the cloud.

Unlike new-build U.K. infrastructure projects such as London’s Elizabeth Line, which are digitally modeled from day one, the Severn Tunnel digital twin retrofits modern methods onto a live, legacy asset—bringing 19th century infrastructure into the 21st century.

From Hawkshaw’s boldness and Lambert’s daring dive into darkness to Nolan’s vision for digital transformation across the Wales and Western railways, the story remains one of ingenuity and progress.

Now that Nolan has captured the Severn Tunnel so thoroughly in digital form, does he still visit the original? “I still visit the tunnel twice a week,” he says, smiling, “traveling at about 75 miles an hour.”