Every once in a while, I hear someone saying that digitalization (or going digital) is the next big thing in the water industry. Don’t look now but digitalization is here, and it has been here for a few decades. At least parts of the water industry have been digital for some time now.

Water utilities have been going digital since computers first became practical in the 1950s. The first people who took advantage of digital technology were the financial folks who realized you could use computers to print bills and keep track of customers who did or didn’t pay.

Maybe these computers weren’t just toys. Let’s take a look at how technological progression has led us to the vibrant and well-established current use of Digital Twin technology.

The Beginning

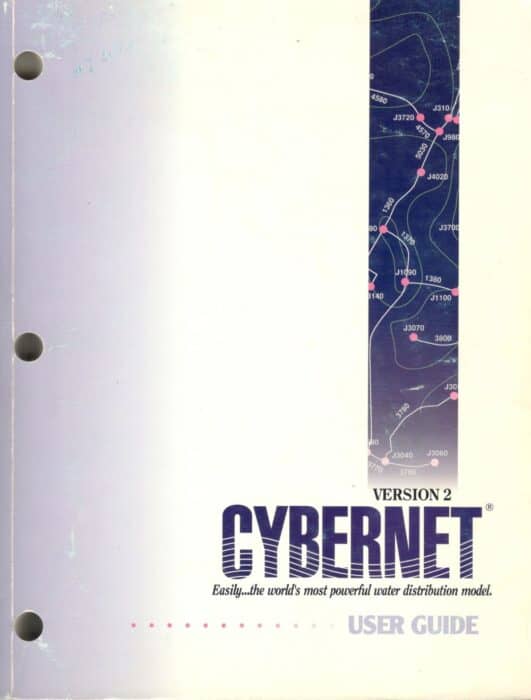

Many network analysis algorithms were developed by universities during the 1960s and 1970s. The 1980s gave rise to the commercialization of this category of software. CYBERNET was released by Haestad Methods (acquired by Bentley in 2004) in 1991.

Many network analysis algorithms were developed by universities during the 1960s and 1970s. The 1980s gave rise to the commercialization of this category of software. CYBERNET was released by Haestad Methods (acquired by Bentley in 2004) in 1991.After finance, hydraulic engineers took advantage of the power of computers. Why? Because solving pipe network problems involve solving thousands, or even millions of nonlinear simultaneous equations. An impossible task manually, but one ideally suited to digital computing. These early models could be considered the first “digital twins” in water. Today very few piping and pumping hydraulic problems are not solved on computers with hydraulic models. Some early models included KYPIPE, WADISO, CYBERNET, and LIQSS.

Next, came design. Drawing plans for projects involved tedious labor with pens and Leroy lettering sets on paper or mylar. Computer-Aided Design (CAD) made drawing and associated revisions and collaboration much easier—and saved a lot of paper. Digitally creating and sharing plans streamlined the design process. Large flatbed plotters replace drafting tables. Now, it may just be a pdf.

Another area to get digitized was work order management. That process also involved paperwork orders which quickly piled up and were hard to keep organized. Computerized Maintenance Management Systems (CMMS) replaced paperwork orders and enabled much easier tracking of work. Today, many maintenance workers carry tablets or laptops in their trucks.

As technology progressed, a draftsman could draw plans with CAD and could also keep system maps on CAD. Then, Geographical Information Systems (GIS) went beyond CAD and actually made pipes have properties like diameter and material. This made digital pipes smarter and helped support asset management, which also evolved from seat-of-the-pants judgment to reproducible, quantifiable processes. The link between GIS (or CAD) and hydraulic models moved modeling forward, eliminating the need for tedious data entry.

Analog telemetry systems that kept track of remote facilities have been around for a long time. However, converting them to digital Supervisory Control and Data Acquisition Systems (SCADA) has enabled this data to be used to support operational decision-making. Analog pen and ink recorders have been replaced by sophisticated digital displays, and databases can provide insights that analog charts couldn’t. Today Internet of Things (IoT) devices have brought new levels of capability and flexibility that are beyond SCADA in some instances.

One of the biggest operational costs for water systems was meter reading. It took a little longer than some of the other digital technologies, but now, Automated Meter Reading (AMR) has taken over the meter reading business feeding customer usage data back into the billing systems which started digitalization in the first place. After a few years, metering companies realized that they could get more from digital metering than just meter readings and moved on to Advanced Metering Infrastructure (AMI) to add more functionality. This has opened doors to big data in understanding customers.

Now and into the Future

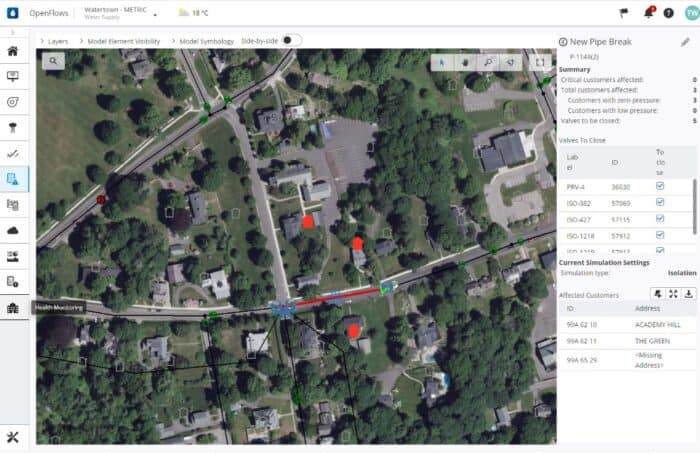

This screenshot shows a water digital twin that bridges GIS data and SCADA data. In this particular example, the digital twin is being used to show isolated pipes and customers without water.

This screenshot shows a water digital twin that bridges GIS data and SCADA data. In this particular example, the digital twin is being used to show isolated pipes and customers without water.So, nowadays, when someone says that we are “going digital,” they need to look around and realize the water industry isn’t going digital—it has gone digital.

Does this mean we are at the end of the digital revolution?

Hardly. We are just another step along the path of digitalization. Each of these digital technologies described above work well for what they were designed to do. But, like children not allowed to interact with others, those digital technologies didn’t learn to play well together either. Over time and one-by-one, interaction became encouraged, and the kids, er digital technologies, started having a lot more fun together.

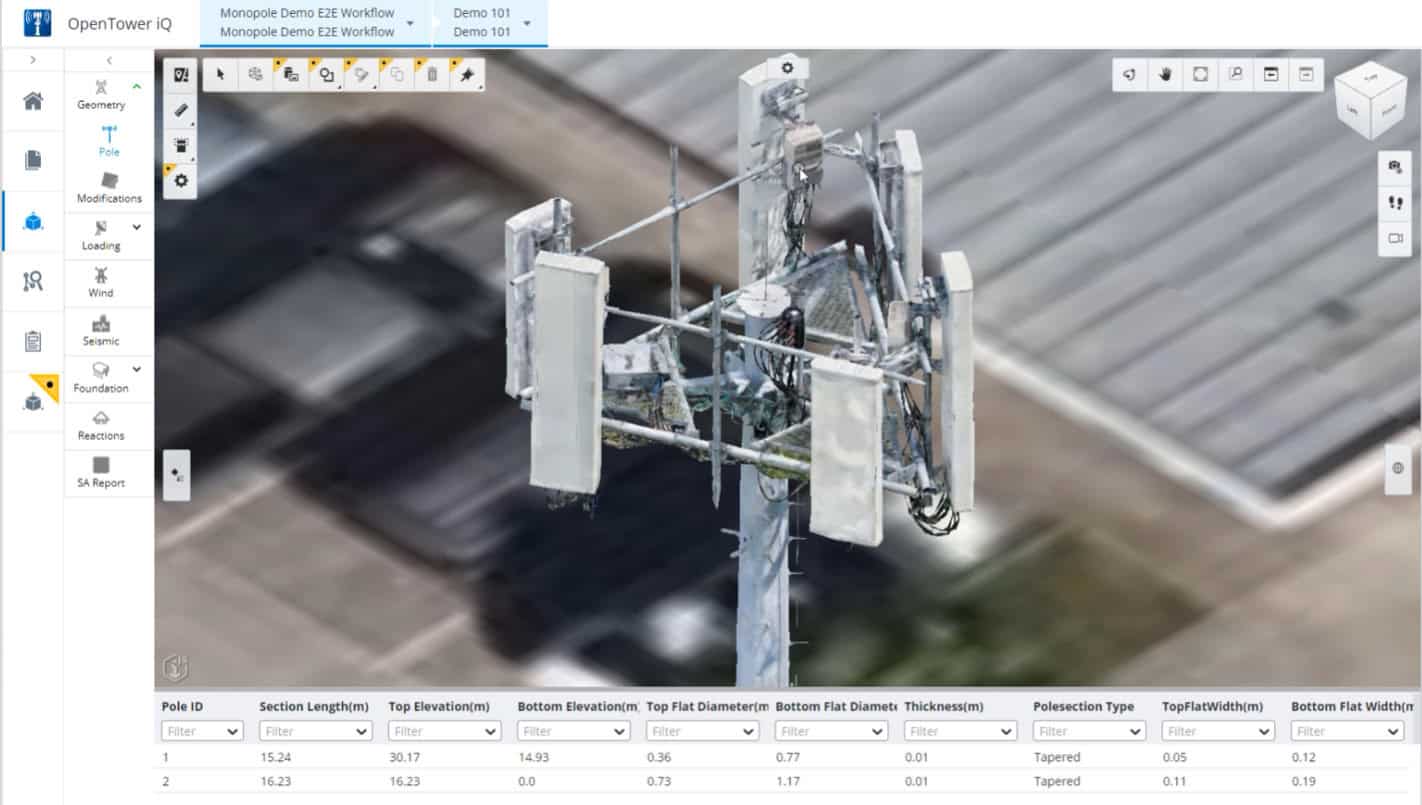

Today, hydraulic models and GIS software can pass data back and forth. SCADA systems can provide the raw material for work orders. Each day, more impressive ways for these systems to collaborate are being advanced. And it’s the collaboration of these systems for the greater good that has taken on the name of “digital twins.” These systems not only contain data for their original, stated purpose, but now can behave like the original real-world system they were supposed to model—a true twin. Now they can support decision-making better than any single software system, and the real water system side of the twin can be built and operated better than ever.

And evolution is not over. Sharing data between digital systems is advancing at breakneck speed. Operations and maintenance personnel, who never thought they would use a computer in their job, are finding their work to be easier and more efficient with digital systems. Research and development teams from across the industry are investing heavily in digital technology. Even in a conservative industry like water, breakthroughs in technology seem to be happening daily. There is no end in sight.

According to Alireza Parhami from DC Water, “In my nearly 20 years of practice as a Hydraulic Modeling Engineer, I have seen firsthand how the advent of IoT and the availability of abundant data shifted the industry from making operational decisions either proactively or using the limited dataset to how to best utilize and leverage the data-rich ecosystem that Water Utilities have access to. Digital Twinning is the vehicle that paves the way and provides endless data-driven decision-making opportunities to the Operations and Engineering staff to mitigate risks, optimally operate the assets and provide superior customer experience to their customers.”