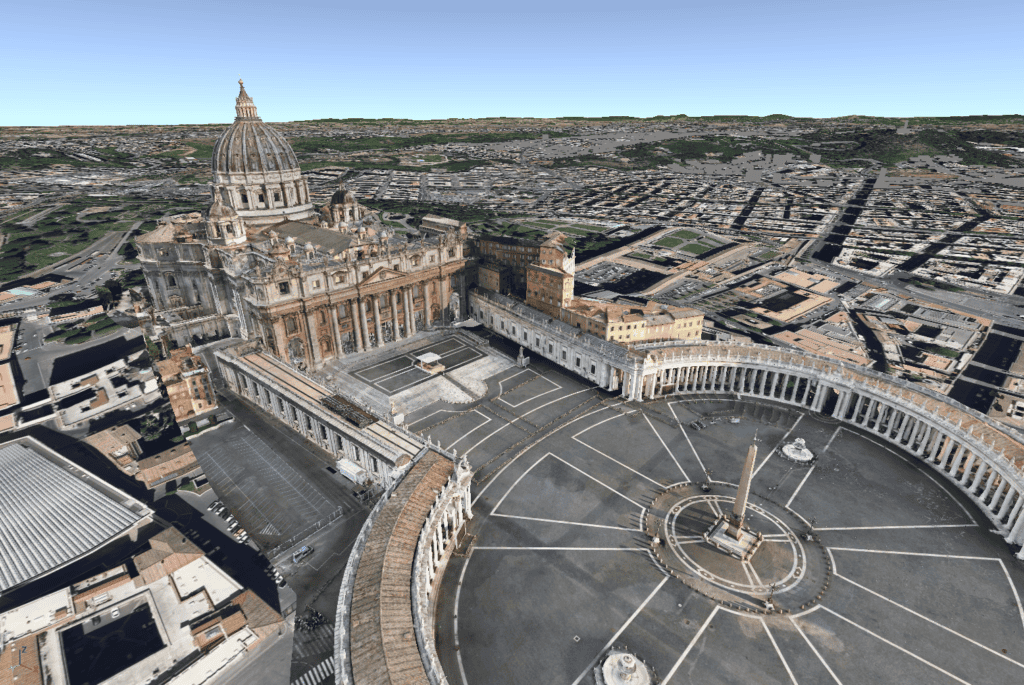

On April 18, 1506, Pope Julius II laid the cornerstone of the world’s largest church on the burial place of the Apostle Peter in Vatican City. More than five hundred years later, every detail of the magnificent cathedral built upon that early foundation is now captured in three dimensions in a virtual model constructed from millions of data points. Saint Peter’s Basilica, one of the world’s most important architectural and religious structures, now has a digital twin to help preserve it for centuries to come.

Exceptional by any measure

Since the early 2000s, digital twins have increasingly been used in industrial and commercial projects, but the opportunity to harness their incredible powers for data visualization and analysis to maintain and restore globally significant sites, such as Saint Peter’s, is just emerging.

“This was our first, and truly unique, digitization project involving such an iconic building,” says Letizia Attili, a building engineer with Italferr, the Italian engineering firm that created the Basilica’s digital twin.

While digital twins have been created for other historic structures, including Notre-Dame de Paris Cathedral, few compare in scale, grandeur, and spiritual and historical value to Saint Peter’s.

A renowned work of Italian Renaissance architecture, one of the holiest Catholic shrines, an important archaeological site of the Roman world, and a major cultural reference point of both Christians and non-Christians, the Basilica also houses a priceless collection of Baroque and Renaissance artwork.

The building, which took 120 years to construct, is itself a work of art, “the fruit of the combined genius of Bramante, Raphael, Michelangelo, Bernini and Maderno,” as UNESCO World Heritage states.

Ralph Waldo Emerson called it “an ornament of the earth…the sublime of the beautiful.”

The St. Peter’s Basilica digital twin captures extraordinary detail of the structure’s interior. Courtesy of Italferr and Italdron Air Services.

The St. Peter’s Basilica digital twin captures extraordinary detail of the structure’s interior. Courtesy of Italferr and Italdron Air Services.The project to create a digital twin of this exceptional building is unique–and uniquely important–for Italferr, which generally works on transportation projects involving roadways and bridges. But the engineering firm, Italy’s largest, has an appetite for innovation and a taste for new technologies, including using 3D mapping technology on archaeological sites.

“This digitalization project not only deals with a building, even one as challenging as the Basilica, but it also deals with an institution that is ancient, like the Basilica itself,” Letizia says.

Italferr was hired by the Fabbrica di San Pietro, or Fabric of Saint Peter, an institution founded close to 520 years ago, the same year construction of the Basilica began, to oversee its conservation, maintenance, and use during a milestone moment.

Next year, the Vatican will host the 2025 Jubilee Year of Hope, the first such event in 25 years. An estimated 35 million people are expected to flock to the Eternal City for the event, according to the Catholic News Agency, which describes a jubilee as “a special holy year of grace and pilgrimage in the Catholic Church.”

Preparations are underway, including renovation and restoration projects. The digital twin will provide valuable information about the Basilica’s structural health, ensuring it is in top shape for the much-anticipated Jubilee.

An extensive, ingenious survey

A white balloon as tall as a person floats gently through Saint Peter’s soaring nave, gathering visual and other data to create the digital twin.

The helium airship and its digital eye was an ingenious response to a key project challenge: how to safely survey the Basilica’s sprawling, jewel-box interior spanning 24 altars, eight chapels, and multiple aisles without putting at risk its exquisite architectural features and extensive artworks, including numerous paintings and frescoes, over 40 statues, and 25 monuments?

The airship was one of a variety of “reality capture” tools Italferr used to gather images and measurements, including topography, laser scanning, aerial photogrammetry, drones, and georadar.

“We used different techniques in order to capture every corner of the Basilica with the highest level of precision possible,” Letizia says. They worked at night and off-hours to limit interference with the building’s activity, including thousands of daily visitors.

A large helium filled balloon was one of a variety of “reality capture” tools Italferr used to gather images and measurements. Courtesy of Italferr and Italdron Air Services.

A large helium filled balloon was one of a variety of “reality capture” tools Italferr used to gather images and measurements. Courtesy of Italferr and Italdron Air Services.The Basilica’s enormous historical and spiritual value is matched by its immense size. Spread over 23,000 square meters, soaring 136 meters high, and running 218 meters long, it can hold up to 60,000 people. As R.A. Scott describes in the Wall Street Journal, “Pope Julius II imagined a miracle in stone that would dwarf the epic constructions of the Caesars and proclaim the power and the glory of Christ and his church.”

Its epic scope is reflected in the massive information cache the surveys gathered: 26,000 files – more than three terabytes of data.

From this treasure trove of images and information points, they not only built a model with millimeter-precise measurements but incorporated geospatial information The digital twin also incorporates any surviving historical reference data about the building and will ultimately include IoT sensor data for ongoing monitoring.

Bentley software, including ProjectWise, iTwin Capture, and MicroStation, was used by Italferr to process and visualize the data. These cutting-edge programs saved Italferr 50 hours in modeling time, allowing its team to deliver its model 20 days ahead of schedule.

More importantly, the project has set the bar for monitoring the world’s most precious cultural, historical and religious sites. It’s a model of how cutting-edge innovation, including artificial intelligence and machine learning, has great value today and moving forward in a sacred building that’s more than half a millennium old.

A model of wonder

The 16th-century architects and builders who conceived of and constructed Saint Peter’s used scale models in wood or clay and hand-drawn patterns to guide their crews of workers and artisans.

In 1514, when Raffaello Sanzio da Urbino, known commonly as Raphael, was named head architect, he added another dimension to the renderings, making drawings with three views: ground plan, elevation, and section.

We can only guess at the wonder with which Raphael might behold the digital twin of today, a dynamic, data-dense model in three dimensions of unprecedented accuracy and detail. Fully navigable, it lets users zoom within millimeters on every aspect of the building’s architecture and art, inside and out, and all in proper scale and proportions.

Even for contemporary users, including designers, engineers, and other partners focused on the Basilica’s maintenance and care, this level of easy, web-based access to a wealth of information is impressive, unlocking a new world of possibilities for heritage preservation.

While impressive in it’s current state ,Italferr’s work with the digital twin isn’t yet complete.

“Our main goal was to create a digital twin that could be constantly updated and effectively used by the Fabbrica di San Pietro,” Letizia says. “So when we achieved this objective, we went further to explore new solutions for our client.”

They designed a monitoring system and sets of algorithms that can transform real-time IoT sensor data on cracks and other physical features, as well as things like temperature and humidity, into visualizations and provide clear information about the status of each component of the Basilica. The system will help optimize repair and maintenance, providing insights for ensuring the health of the Basilica amid static and dynamic stresses, both man-made and natural.

Immersive experiences

Beyond the teams of engineers, designers, and contractors who will rely on the digital twin in their work to preserve and protect the Basilica, there are whole other audiences for the immersive digital model.

Digital twins and reality capture can also valuable tools for education. Greg Demchak, Bentley’s VP of Emerging Technologies highlights that “The model has tremendous applications for post-secondary students, academics, and researchers of art history, architecture, and engineering.”

At Bentley’s Year in Infrastructure 2023 annual event, which took place in Singapore last year, Greg and his team showcased a high-fidelity version of the Basilica’s digital twin rendered through Unity’s gaming engine to demonstrate a best-in-class immersive experience with the model.

Beyond its engineering and art historical uses, the model also opens up exciting humanist opportunities. Catholics who cannot make the pilgrimage to the Vatican for the 2025 Jubilee Year of Hope, for instance, may be able to visit Saint Peter’s. The model offers the closest experience yet to being there.

Inside the digital twin, a student, pilgrim, art historian, or engineer can behold, up close, the exquisitely lifelike details of La Pieta, Michelangelo’s masterpiece in marble, or fly over Bernini’s breathtaking Baldacchino, a massive, four-columned structure framing the Papal Altar made from 700 kilograms of bronze and gilded in gold.

Out in the open air, they are free to explore the Basilica’s exquisite exterior from the ground up, including its dome, one of the world’s largest, designed by Michelangelo and completed in 1590. The digital twin gives the user VIP access and wings, providing previously impossible access.

Hovering inside the model, a curious navigator might pause at the dome’s base to read the three-meter-high inscription: “Tu es Petrus et super hanc petram aedificabo ecclesiam meam et tibi dabo claves caelorum,” which means “You are Peter, and upon this rock, I will build my church.”