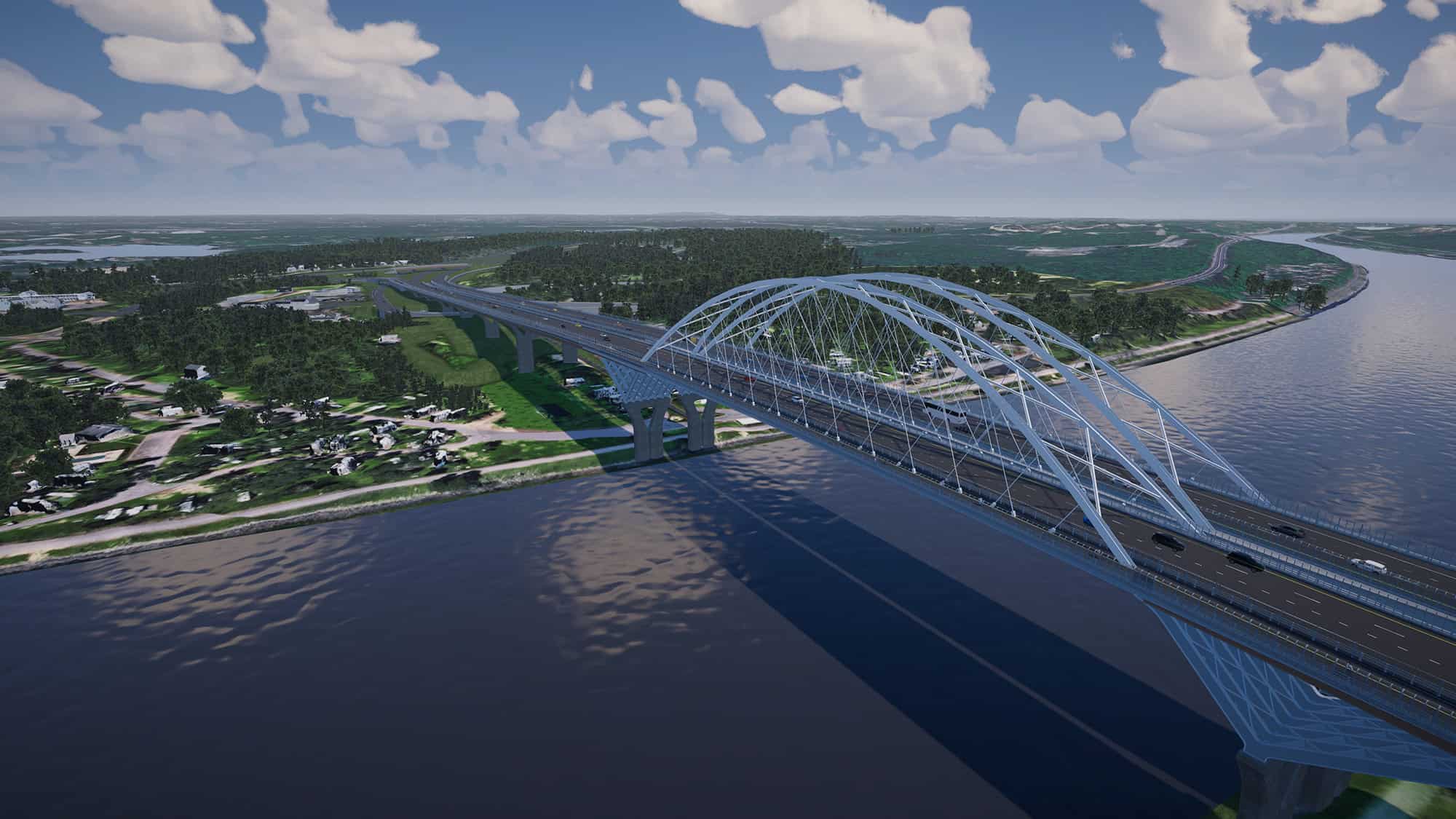

Historic Stone Arch Bridge. Minneapolis, MN

Historic Stone Arch Bridge. Minneapolis, MNAt its peak, the James J. Hill Stone Arch Bridge carried about 50 passenger trains daily into downtown Minneapolis. Built in 1883 and spanning the Mississippi River, the 22-span masonry arch bridge served as a working railroad bridge carrying the Minneapolis Union Railroad over the Mississippi River just below St. Anthony Falls. Thousands of people commuted into and out of the central business district contributing to the fast-growing industrial area.

Sharing this brief background on the Stone Arch Bridge helps to illustrate a point: Transportation is essential to sustaining economic growth and improving the quality of life in a region. The daily movement of people and goods is constantly increasing, as is the size and complexity of projects being imagined, and assets operated. The needs of an area constantly evolve as they are built, restructured, and maintained. This is where reality modeling steps in to help direct the future of transportation planning and construction.

Inspecting a Historic Landmark with Reality Modeling

In the early 1990s, the Stone Arch Bridge was converted into a pedestrian and bicycle pathway. Although it no longer serves as a railway bridge, the 2,100 feet long bridge is the most historically significant bridge in Minnesota and is recognized as a National Civil Engineering Landmark.

To ensure public safety and maintain the cultural value of the bridge, the Minnesota Department of Transportation (MnDOT) hired Collins Engineers, Inc. to assess and restore the structural integrity of the iconic bridge. To identify structural deficiencies and develop repair plans, Collins needed detailed information on the condition of masonry for the entire bridge, including stone arches, embankments, piers, and underwater foundations

Collins selected ContextCapture, a photogrammetry software, to generate a high-fidelity 3D model as the basis of a digital twin of the Stone Arch Bridge from over 13,000 drone-captured images. By creating a digital twin, the team could record field inspection notes directly in the model, improving accuracy. Using Bentley’s reality modeling and iTwin applications facilitated real-time model access, saving 20% of field time. They performed virtual inspections and established a mixed reality environment for the team and public to view the digital twin of the bridge and gain a better understanding of the restorative design works.

What is Reality Modeling and what are the Benefits Throughout the Asset Lifecycle?

Reality modeling is the process of capturing the physical reality of an infrastructure asset, creating a representation of it, and maintaining it through continuous surveys. Photographs and/or point clouds, when additional accuracy is needed, are used to create high-fidelity georeferenced 3D models. These reality models can be easily and consistently shared, consumed, and accessed, on desktop and mobile devices, in many formats throughout the lifecycle stages – design, construction, and operations – of an infrastructure asset.

Design: Providing real-world digital context of existing conditions

- Simulate construction and evaluate potential impact

- Understand financial implications early

- Accelerate and improve decision making

- Optimize collaboration and coordination

- Leverage digital workflows

- Manage and mitigate risk

Construction: Monitor and evaluate progress, and enable verification of performance against schedule

- Ease collaboration among stakeholders

- Provide up-to-date documents for construction and inspection

- Conduct calculation of cut/fill quantities as required

- Improve safety and enable right-first-time construction

- Lower costs to perform as-built surveys

Operations: Improving operations and maintenance through easier

capture and documentation of assets

- Optimize maintenance and service activities

- Lower asset inspection costs

- Improve safety and coordination

- Develop more repeatable inspection processes

- Provide easier access in hard-to-inspect locations

Digital Twins Start with Reality Modeling

A key component of a digital twin is the digital context which is made by a combination of captured reality data types such as image-based reality meshes, LiDAR point clouds, digital terrain models, mobile imagery, and GIS sources. It’s the aggregation of any 3D reality data captured on actual assets at different times, using a variety of techniques such as photogrammetry, laser scanning, trajectories, control points, 360 panoramas, and targets.

The reality mesh of the Stone Arch Bridge provides real-world digital context, serving as the basis of a digital twin.

The reality mesh of the Stone Arch Bridge provides real-world digital context, serving as the basis of a digital twin.The digital context reflects all geometrical, visual, and geospatial aspects of the actual asset at the time of capture, at any scale, and enables multiple new cost-saving workflows like online collaboration, remote inspection, virtual operations, in-context design, and mixed reality applications. These highly detailed reality models are used to provide precise real-world context for design, construction, and operations decisions for use throughout the lifecycle of an infrastructure asset.

As illustrated by the Stone Arch bridge project, reality modeling provides real-world digital context that serves as the basis of a digital twin, but what are the critical criteria to achieve a great digital context?

Precision and Trustworthiness

To reduce on-site visits, a digital twin must reflect relevant details of the asset. The precision and the exhaustivity of the modeling enable remote operations as well as decision-making processes. Digital context becomes a piece of trustworthy information that stakeholders can use to collaborate upon, assess, annotate, and share. Such a level of confidence requires controlling the entirety of the generation process, from the acquisition, by selecting the most appropriate capturing device and methodology, to the fusion of data and metadata into a single model.

Hybridity and Reality Data Convergence

To properly render all needed details and support multiple workflows, 4D digital context depends on various capturing techniques and reality data fusion. The combination of photos, providing a high resolution of information on the geometry and condition of an asset, point clouds, acquired at high precision and density, and metadata like control points and trajectory, improves the quality of the reality models.

INFRASTRUCTURE: The Work to Improve the Future of Transportation is Happening

Time is of the Essence

Capturing reality content provides a 3D picture of the actual conditions at any given time enabling measurement and visual understanding, but the value of any data resides in its trustworthiness. 3D reality models regularly capture the latest conditions to truly enable remote and virtual operations, saving time and improving safety. Moreover, archiving 3D reality models captured at various times during the construction or operation of an asset helps to better analyze and resolve issues, and improves collaboration across the entire lifespan of an asset. This is where we introduce 4D.

Particularly sensitive to the time dimension, construction companies are now implementing 4D planning and want to monitor their progress through the recurring, frequent capture of existing conditions on the construction site. Asset management professionals also want to virtually inspect their assets at specific times to track changes and better plan maintenance operations. 4D digital context also provides information on the condition of an asset at different times, providing valuable insights into its evolution. The time-stamped instances of the 3D model can be used for archiving, resolving issues, asset performance management, or for changes and progress monitoring on a construction site.

From Creation to Management

The creation of a 4D digital context model starts with the initial acquisition of reality data on an asset at the proper resolution and scale. Its continuous update and management along the lifespan of the asset require multiple tools.

Capturing the Context with Reality Modeling

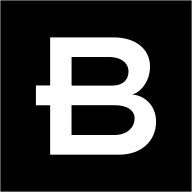

Bentley reality modeling solutions, whether on-premises or in the cloud, can convert drone and/or ground imagery, as well as any point clouds, into a broad range of reality content formats, from multiresolution meshes optimized for large scale models visualization and streaming to neutral geometrical exchange format to dense and massive point clouds. Using photogrammetry and computer vision techniques, reality modeling solutions automatically detect the orientation and position of photos, georeference the model in thousands of possible spatial reference systems, and convert dense point clouds into highly streamable formats.

Managing Unlimited Volumes of Reality Data

A digital twin must reflect all aspects of the actual asset. Therefore, results are derived from the combination of multiple and recurring reality modeling operations. This implies storing, archiving, and managing a large quantity (terabytes or petabytes) of reality data, and providing easy and constant access to stakeholders at any step of the asset’s lifecycle. Since a 4D digital context often results from the fusion of multiple reality data with various formats and acquired at different times, it is critical to rely on a management solution that is versatile enough and will scale with users’ needs.

Adding Intelligence to the 4D Digital Context

Even though high accuracy, full-scale, photorealistic digital context already provides a lot of value to users, more can be done to help improve operations. For instance, automated object recognition can be used to quickly generate inventories, where equipment can be localized, georeferenced, and identified in the 3D model. Through artificial intelligence, machine learning, and geometrical analysis techniques, as well as semi-automated processes, Bentley reality modeling solutions allow users to better understand the real-world context, extract insights from the reality model, and link it to other business information.

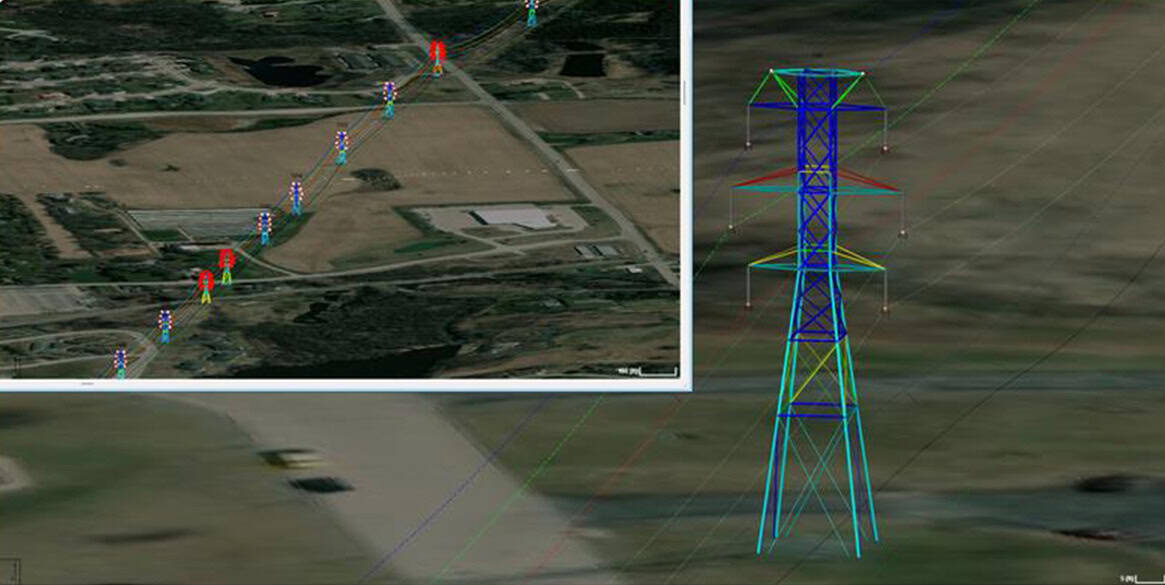

For instance, detectors trained through machine learning can automatically identify objects in photos and defects on a structure, then localize them in the model. It is very useful to automatically classify equipment like pumps or valves in a plant, lighting poles or street furniture in a city, or cracks on a dam or bridge. Detecting cables or breaklines on a street or building can be done very easily in a few clicks to vectorize key structures. This technology can also be applied to the assisted 3D inventory of complex subjects like poles or trees.

INVESTING IN DIGITAL TWINS: Here’s Why Investors are Starting to Pay Attention

A Collaborative Environment for Project Stakeholders

A digital twin is a single source of truth that all project stakeholders refer to, to make informed decisions. This means that beyond the intrinsic value of the digital context, it is critical to make the digital twin available to field and office workers, who will analyze it, annotate it, and edit it, in collaborative workflows that improve communication, facilitate the preparation and execution of operations, and reduce risks due to misunderstandings. Bentley’s reality modeling solutions enable users to easily publish a 4D digital context on local or hosted servers and provide secure access to the reality data and models all along the asset lifecycle.

Owner-operators and their supply chains need effective and efficient solutions to design, build, and operate road networks around the world, and are adopting reality modeling to improve worker safety, start projects faster, iterate designs more efficiently, and share information more effectively. Bentley’s reality modeling solutions help roads and bridges owners and their engineering consultants from around the world to capture, manage, analyze, and share their digital context. Using advanced digital technologies to survey the Stone Arch Bridge allowed Collins to shorten the time that the bridge was out of service during inspection and then reopen it for the community to continue to enjoy this cultural landmark.