Before the cardinals of the Roman Catholic Church gathered in the Vatican to elect the leader of the world’s largest Christian church—ultimately choosing Cardinal Robert Francis Prevost as Pope Leo XIV—they attended a special Mass in the imposing grandeur of St. Peter’s Basilica.

The magnificent cathedral, completed almost 400 years ago, has been front and center in the weeks since Pope Francis died on Easter Monday at the age of 88. It’s where Francis lay in state as the faithful filed by to pay their final respects. It was from its steps that Cardinal Giovanni Battista Re presided over the pope’s April 28 funeral mass, in front of more than a quarter of a million mourners in St Peter’s Square. And from its balcony, Francis’ successor, Pope Leo XIV, appeared on Thursday in front of the expectant crowds gathered below, shortly after they heard the famous phrase, “Habemus papa”—“We have a pope.”

The announcement that a new pope was elected follows centuries-old traditions. There’s the white smoke over the Sistine Chapel and the ringing of St. Peter’s bells echoing throughout the Vatican. But as Leo XIV begins his papacy, the Basilica, an architectural marvel of the Renaissance and the burial place of the Apostle Peter, also has a very 21st-century innovation of its own: a digital twin, or virtual 3D replica.

The St. Peter’s Basilica digital twin captures extraordinary detail of the structure’s interior. Courtesy of Italferr and Italdron Air Services.

The St. Peter’s Basilica digital twin captures extraordinary detail of the structure’s interior. Courtesy of Italferr and Italdron Air Services.The digital twin was created by Italy’s largest engineering firm, Italferr, to help preserve this unique piece of religious and cultural heritage for centuries to come.

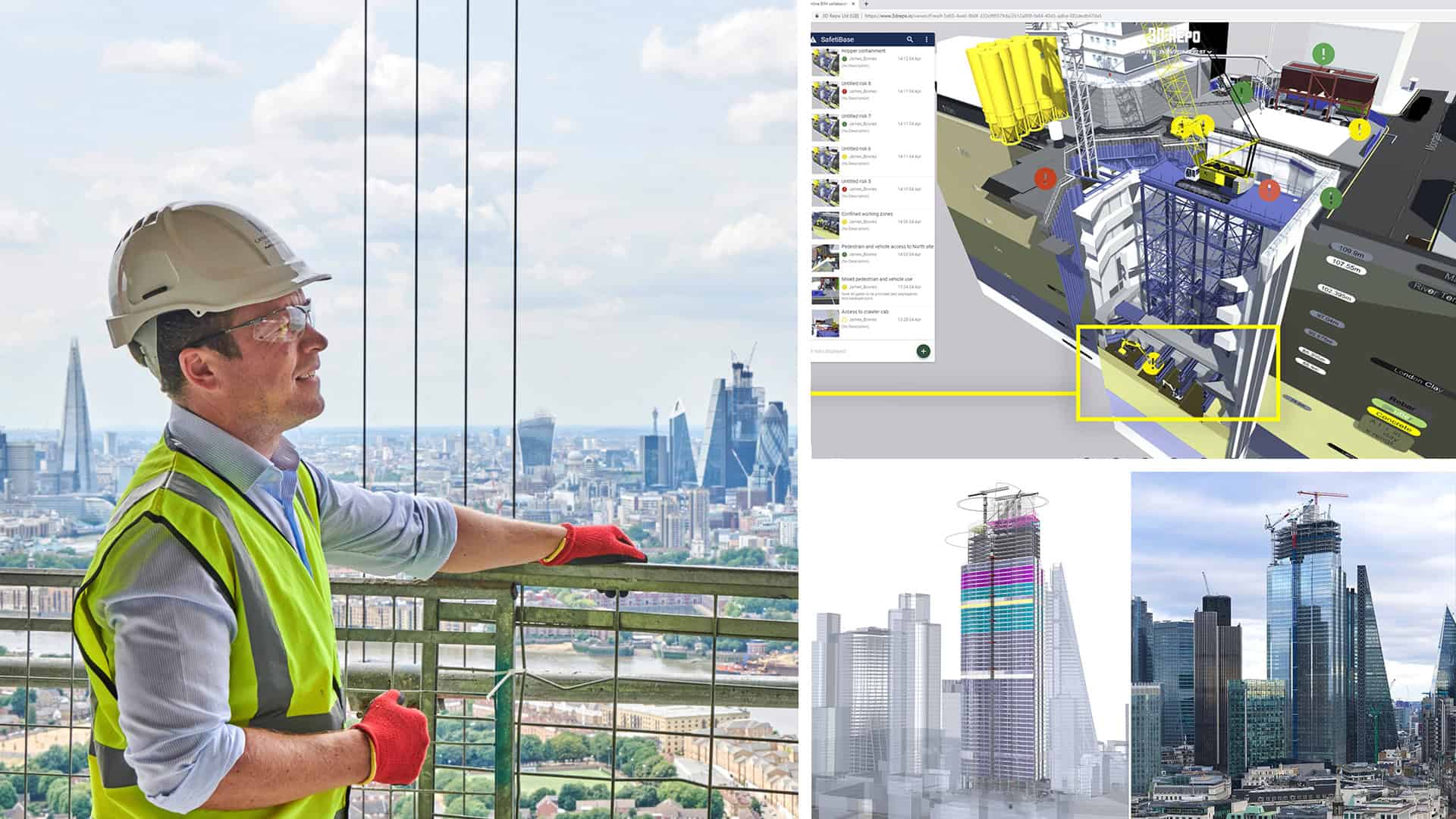

Italferr, best known for its work on roads and bridges, built the Basilica digital twin with the aid of software from Bentley Systems, the infrastructure engineering software company. First, engineers used the latest technology, including laser scanning and photogrammetry—along with aerial devices to float a special balloon inside the structure, soaring 136 meters high and running 218 meters long—to gather internal and external images and measurements, including tiny cracks and other details measuring just millimeters. They used a whole suite of Bentley software—including iTwin, Bentley’s platform for infrastructure digital twins— to combine 26,000 files holding more than three terabytes of disparate data—enough to store 700 feature movies in high video quality. The software and the data allowed them to create the digital twin model in a cloud-based platform.

“For a lot of software, it’s really difficult to combine all these different types of data, and with iTwin Capture, they were able to combine that, to create high-fidelity models and to share that with 30 people [on the] project,” says Aude Camus, Bentley’s senior product marketing manager of iTwin Capture. Camus describes the Basilica digital twin as the best reality-capture project she’s seen.

Moreover, using such technology saved hundreds of hours, “reducing the on-site inspection needs,” Italferr’s Davide Porzio told Bentley.

A Solution Lighter Than Air

A surveyor with a balloon equipped with cameras inside St. Peter’s Basilica.

A surveyor with a balloon equipped with cameras inside St. Peter’s Basilica.One major challenge was how to safely capture the Basilica’s priceless interior in intricate detail, where conventional drones might cause damage. The solution: an airship made up of a helium balloon as tall as a person, carrying reality-capture systems.

The digital twin allows users to “ascend” into the Basilica’s dome, or to zoom in on a masterpiece of Italian art and architecture such as Michelangelo’s marble La Pieta or Bernini’s bronze and gold Baldacchino, which frames the Papal Altar.

The project’s main application will be to help in the maintenance and preservation of the iconic Basilica, which can hold 60,000 people.

“You have thousands of people going there every day. By having a digital twin, you can do monitoring remotely, so you don’t have to close the Vatican,” says Camus. “And because it’s a really old monument, they didn’t have the 2D plan of everything. So now they are really able to know exactly the geometry … and to use that for monitoring purposes.”

Ultimately, the monitoring system will include sensor data from the internet of things (IoT) to provide clear and timely information about the state of the Basilica’s physical features, helping optimize repairs and maintenance.

The project is of “extraordinary value” not just in engineering, but also in social terms, says Italferr’s Daniela Aprea: “It will make it possible to preserve in the decades to come the full functionality of the work that is the centerpiece of the Christian faith throughout the world.”