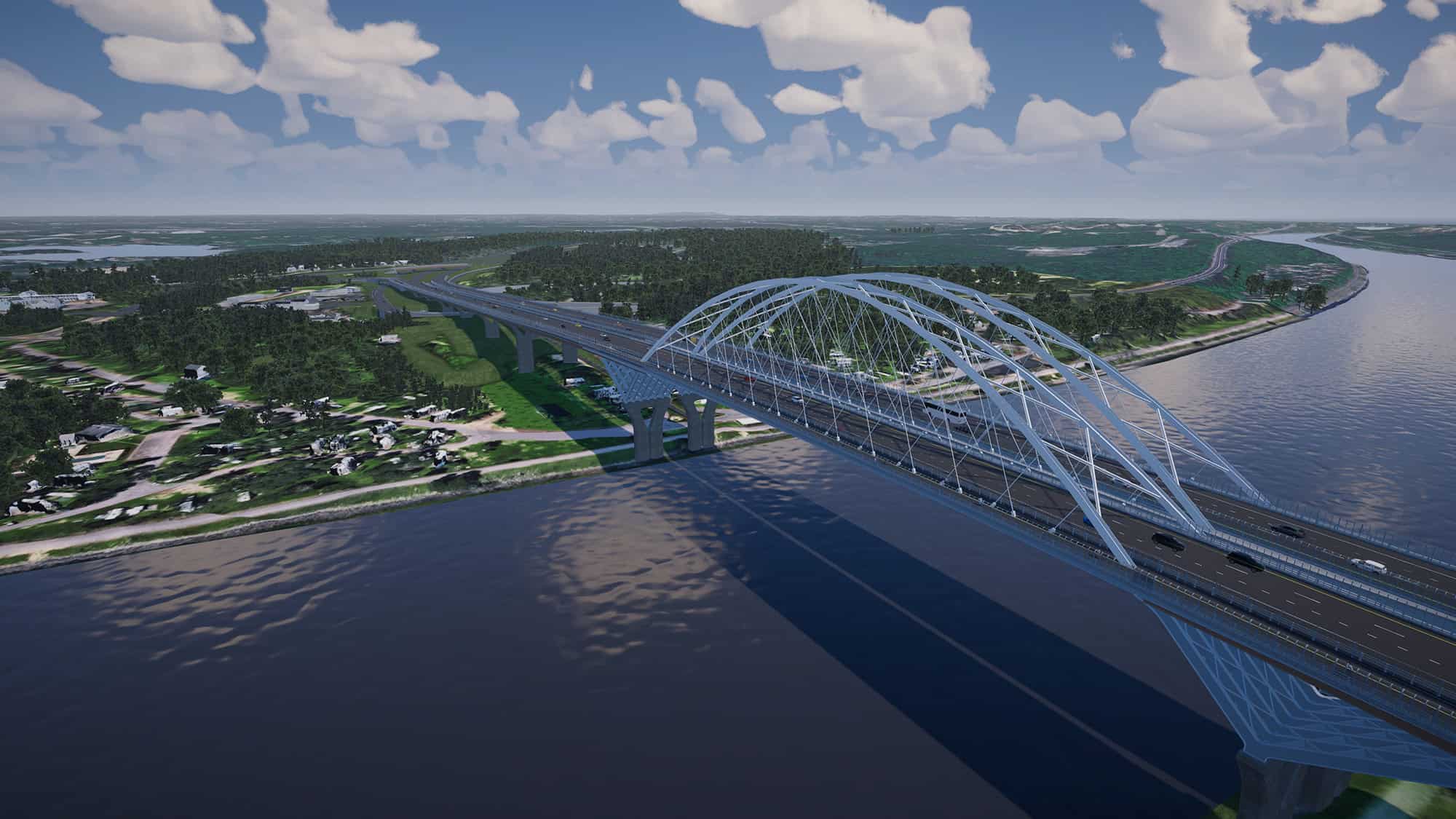

New York State’s Department of Transportation set a new standard for using a digital twin as the primary contract document. Video courtesy of NYSDOT.

New York State’s Department of Transportation set a new standard for using a digital twin as the primary contract document. Video courtesy of NYSDOT.Commuting is a fact of life for many metropolitan areas, but very few accommodate anywhere near the 1 million commuters that crowd into Manhattan each day.

To maneuver around highways, waterways, and other potential obstructions, New York City’s commuters depend on an impressive array of bridges and tunnels. One of those bridges is the 138th Street Bridge in the Bronx. At first glance, the bridge’s importance may not seem apparent – with six lanes of traffic, the 100-foot bridge is wider than it is long, making it seem like just another small piece of the city’s sprawling network of roads.

But there is more to the 138th Street Bridge than meets the eye. It is a critical artery that leads into Manhattan with 150,000 vehicles crossing it every day, many of them on their way to the landmark Madison Avenue Bridge just 25 feet to the west which crosses the Harlem River into Manhattan. Additionally, the bridge provides a key link to Yankee Stadium to the south and is part of the New York City Marathon route.

Though relatively small, hundreds of thousands of New Yorkers regularly rely on the bridge. Originally built in 1938, the bridge has seen a swell of traffic demands and has experienced vertical clearance issues over the years, all culminating in the New York State Department of Transportation’s decision to replace the bridge.

Hidden Complexities

Replacing a short-span bridge might seem like an easy task but the 138th Street Bridge is much more complex than it might seem to the casual observer. To start, the sheer volume of traffic and the lack of nearby alternatives for crossing the Harlem River into Manhattan makes completely shutting down the bridge impossible. Residents, commuters, businesses, and visitors alike rely on the bridge and on the Major Deegan Expressway, another of the city’s major arteries that runs directly underneath the bridge. Without careful planning, the bridge replacement could disrupt travel across two roads.

Additionally, the 138th Street Bridge is located in a densely packed urban environment and contains a concealed, complicated web of various utilities beneath the road that the team needed to either relocate or design around. Designing the bridge to fit in with the architectural landscape and meet a long list of other restrictions added even more complexity.

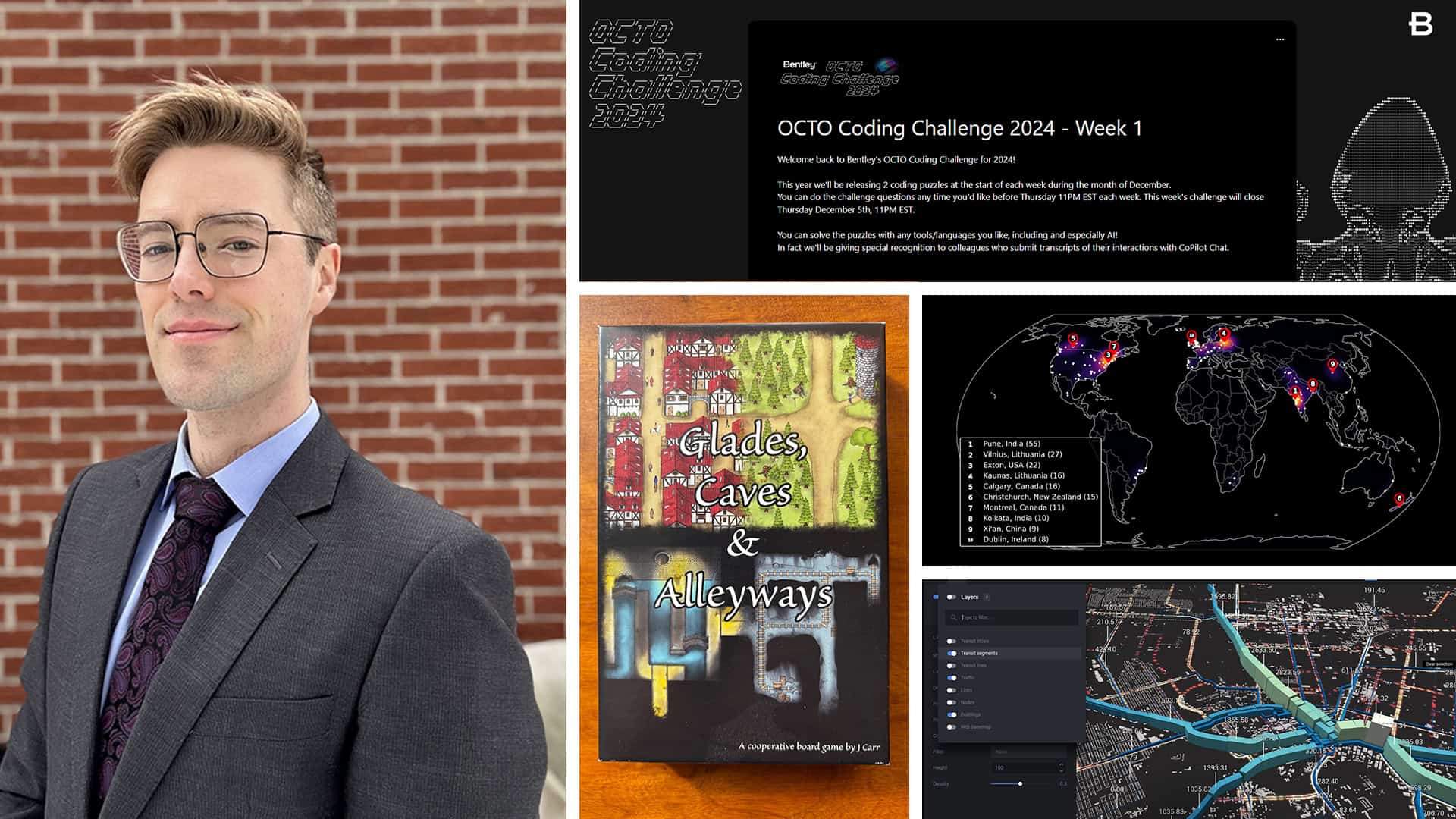

Historically, a project of this magnitude would require stakeholders to review hundreds of paper plan sheets. The NYSDOT needed a more effective approach to gain buy-in and to ensure the overall success of this 47-million-dollar replacement project. They used the project as an opportunity to advance towards digital delivery and pilot model-based contracting, the first project of its kind for the state.

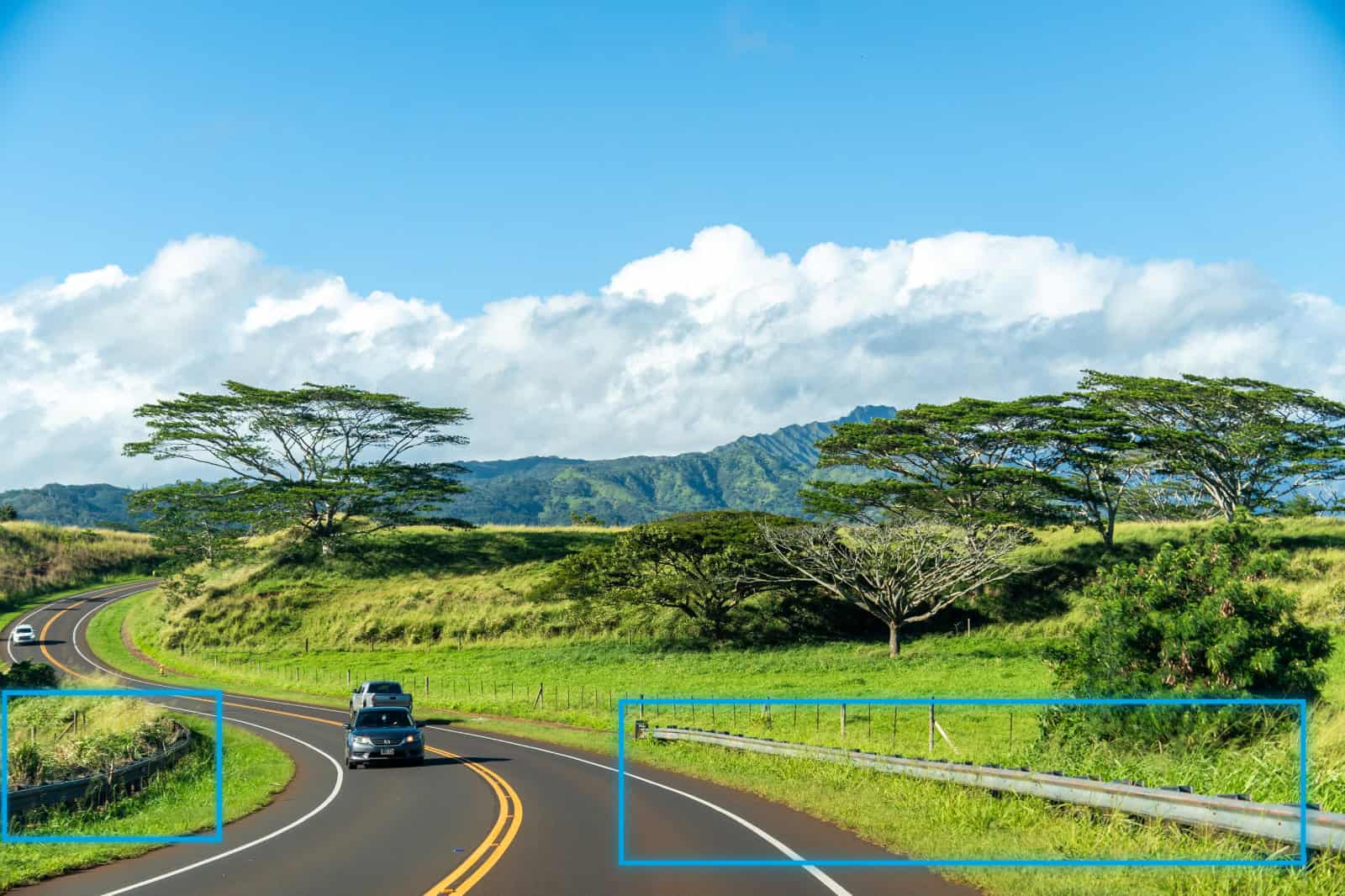

A rendering of NYSDOT’s 138th Street Bridge shows a complicated web of utilities below the surface. Courtesy of NYSDOT.

A rendering of NYSDOT’s 138th Street Bridge shows a complicated web of utilities below the surface. Courtesy of NYSDOT.NYSDOT is Advancing Towards Digital Delivery

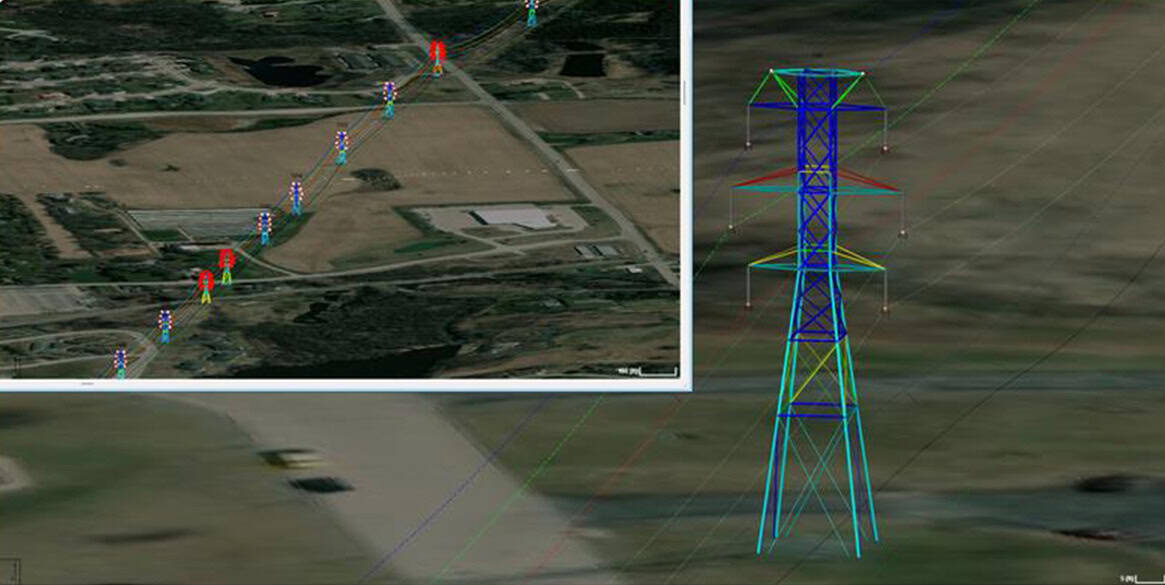

Bentley software was used by the project team to develop a digital twin of the entire bridge structure and surrounding area to such a level of detail that the team could use the models contained within that digital twin as the legal contract document.

Use of the digital twin helped facilitate communication across disciplines and stakeholder groups. Being able to visualize the site in 3D helped the team better understand the project and quickly experiment with different design options to determine the most effective solutions. The approach helped to resolve costly issues before construction and accelerate the design process.

For example, the team examined different design methods to accelerate construction and minimize the impact to traffic and pedestrians. By simulating the construction process within the model, they determined how to construct the new bridge in four phases, all of which left room for traffic and pedestrians to continue their regular commutes.

Being able to see what the project will look like when completed eliminated any guesswork and helped fine-tune all elements. Bridge aesthetics will blend in with the surroundings. Bicycle and pedestrian paths will be ample and safe. Curbs will be intelligently placed where needed. And all project details were clearly communicated to project partners and the public, helping NYSDOT to gain approval and ease concerns.

More than 180 reviewers across 15 agencies were given access to the model to flag and comment on potential design challenges without having to review over 200 traditional plansheets which was vital for gaining approvals. An animated rendering of construction strengthened public outreach, helping everyone understand the project’s developments and road closures within minutes.

The pilot project was deemed a success, with the winning contract bid 15% lower than anticipated, and long-term savings and efficiencies in asset management and inspections are now possible. Digital delivery helped reveal critical details of this deceptively complex project and clears the way for more informed decision-making during the entire lifecycle of the project.

Over 180 reviewers across 15 agencies were given access to the model to flag and comment on potential design challenges. Courtesy of NYSDOT.

Over 180 reviewers across 15 agencies were given access to the model to flag and comment on potential design challenges. Courtesy of NYSDOT.Transitioning to the Future

The 138th Street Bridge project is just one of many examples of how DOTs across the U.S. are advancing toward digital delivery. Funding from the Infrastructure Investment and Jobs Act (IIJA) is now flowing to DOT projects across the country. However, there are not enough skilled workers available for the projects already in progress, let alone the new ones being funded.

DOTs in at least nine states have begun or completed pilot projects focused on using 3D models as the primary source of project information. With technology that enhances digital delivery, DOTs can stretch their budgets further and create more innovative, sustainable projects while keeping project teams at the same size.

Software plays the starring role in this transition, and, as THE infrastructure engineering software company, Bentley is here to help DOTs and project delivery firms advance to digital delivery with our roads and bridges solutions.