James Bowles has always loved building things. As a child, he spent hours with Lego, piecing together miniature cities brick by brick. As a teenager, he became fascinated by skyscrapers—their design, engineering, and sheer scale. It wasn’t just their height that intrigued him, but the challenge of making something so ambitious stand.

Today, Bowles is helping shape the skylines he once admired, revolutionizing construction planning with 4D modeling, which connects time and space, and digital twins. His work bridges the visionary concepts of architects with the practical expertise of builders, ensuring that complex structures rise with fewer surprises. Now in Jeddah, Saudi Arabia, Bowles is helping bring to life the kind of architectural ambition that first captivated him—the tallest skyscraper the world has ever seen.

Falling in Love with the Build

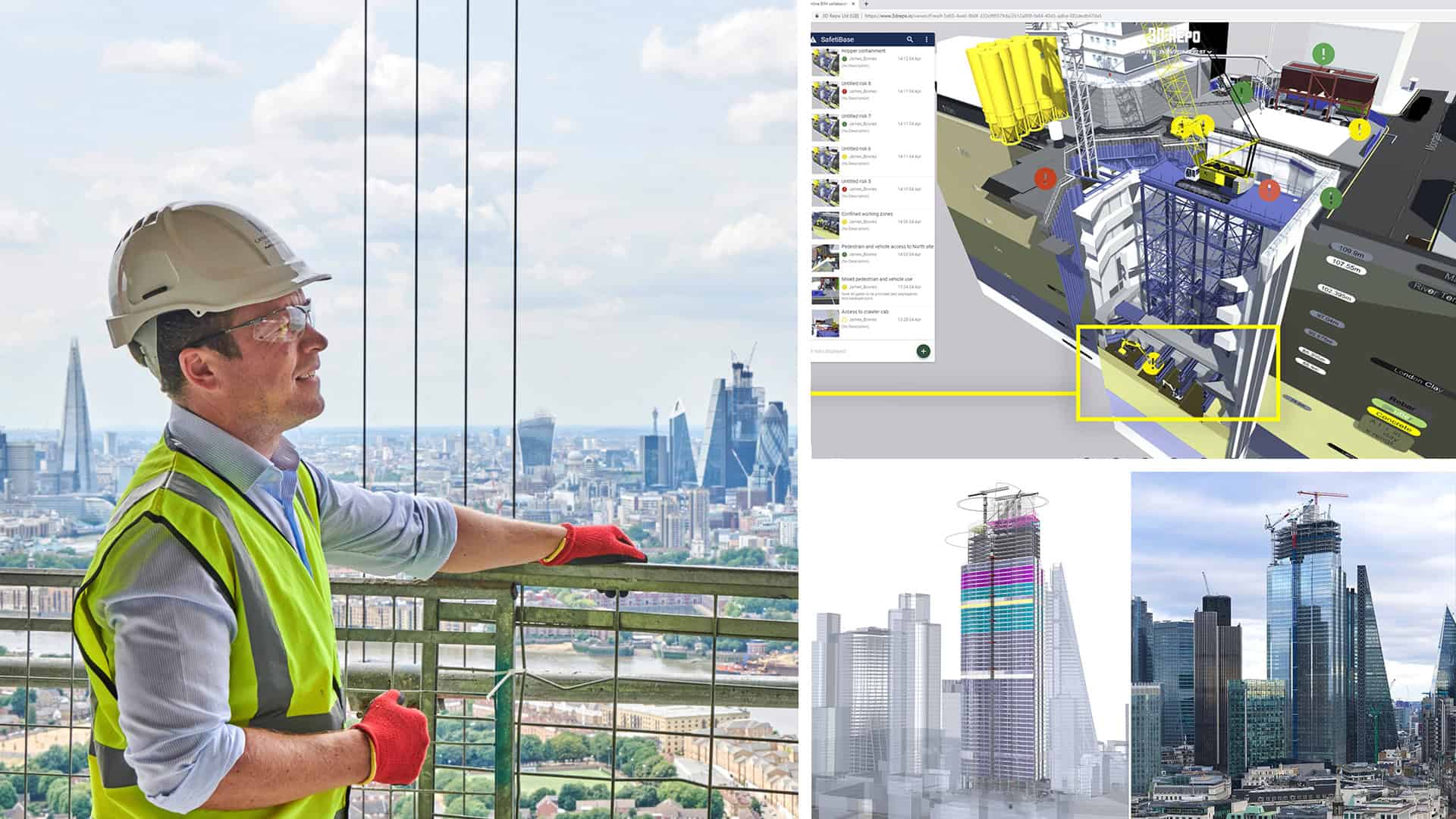

James Bowles captured in his natural environment, a sky-high build.

James Bowles captured in his natural environment, a sky-high build.Bowles pursued his passion at the University of Sheffield, enrolling in one of the U.K.’s rare dual-degree programs in architecture and engineering. The courses demanded a balance of structural problem-solving by day and creative design work by night, giving him a foundation in both disciplines.

He went on to join BAM Construction in 1999, where he started in the design office. “It was a classic office environment, with engineers sitting quietly, working diligently,” he recalls. It was fine as far as it went, but everything changed the day Bowles was seconded to a construction site.

“Suddenly I was working as a site engineer in a construction team of hundreds, surrounded by tower cranes, excavators, and piling rigs. Banter over a quick bacon sandwich, the team spirit—everything just clicked.” Bowles was hooked. “I remember thinking, ‘I’m helping to build Great Ormond Street Hospital, and they’re paying me to do it? This is crazy.’” This was Lego with real-world impact, and he would have done it for free.

The Darwin Centre: The Power of 3D Models

One of Bowles’ most technically demanding projects at BAM was the build of Darwin Centre Phase II at the Natural History Museum in London. The project included an eight-story, curving concrete cocoon encased within the outer shell of the building. The structure’s freeform shape made it difficult to convey using traditional plans. “It was impossible to understand in 2D,” says Bowles.

To help coordinate the build, which began in 2006, Bowles was asked to create a 4D model using design software. “It was a bit of a hack,” he says. “We built a model with elements that could be toggled on and off in sequence, creating a stop-motion-style animation—like flipping through a Lego manual for the build.”

It worked. Construction teams used Bowles’ visualizations daily, coordinating everything from scaffold placements to concrete sprays, and he emerged from that cocoon with his outlook transformed. He’d seen the power of digital construction planning as a way to visualize and de-risk construction before it happened—and his evolution was set.

The Founding of Freeform

After finishing the Darwin Centre, Bowles became evangelical about using models to improve construction planning. But in these early days of the technology, it was an undervalued part of the industry. “There was no obvious role for me to keep doing it inside BAM,” he says. So, without a business plan or any guaranteed work, he left and ultimately founded Freeform in 2007.

For its first few years, Freeform manually built sequencing models, which connect construction schedules and other important engineering contexts to 3D design models, using whatever software they could bend to their purpose. Then Bowles discovered SYNCHRO 4D. “This whole hack we’d been doing—this was the tool actually built for it,” he says. “It was perfect.”

Now part of Bentley Systems, the infrastructure engineering software company, SYNCHRO also allowed Freeform to connect construction schedules and activities directly to 3D models, enabling teams to visualize the build over time. No more workarounds—now, they could create true 4D models, dynamically linking time and space.

Early on, the models were focused on planning. “It wasn’t so much about communication with the workforce, and so we weren’t getting the expertise from the people actually fitting the steel—which would have been helpful,” he says. That changed as Freeform refined its approach and used more of SYNCHRO’s growing capabilities. Bowles’ models began incorporating access routes, hoisting logistics, formwork, and concrete pouring sequences, making the technology indispensable for the entire project lifecycle. Most importantly, SYNCHRO enabled seamless collaboration—bringing together engineers, planners, and site workers to visualize construction in a shared digital space.

That shift was about to pay off in a big way.

Crossrail: The Power of Getting People in the Room

One of Freeform’s major successes with SYNCHRO came in 2012 with Crossrail. The massive rail project, now known as the Elizabeth Line, installed 118 kilometers (73 miles) of tracks under London and connected its suburbs in the east to center and to Heathrow Airport in the west. Passengers have already taken hundreds of millions of trips on the underground line since it opened in 2022.

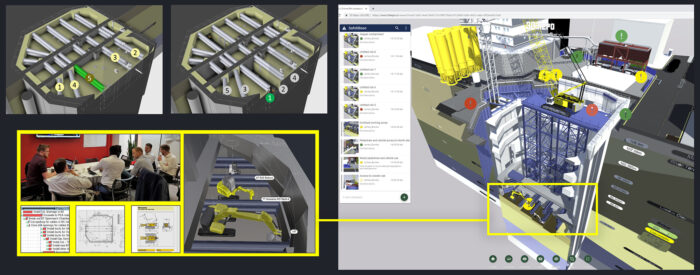

Looking at Freeform’s SYNCHRO 4D model of Crossrail’s Moorgate Shaft, it was clear to an experienced digger operator that there wouldn’t be sufficient room to maneuver. Image courtesy of Freeform.

Looking at Freeform’s SYNCHRO 4D model of Crossrail’s Moorgate Shaft, it was clear to an experienced digger operator that there wouldn’t be sufficient room to maneuver. Image courtesy of Freeform.At Moorgate shaft, a pivotal excavation, Bowles was leading a planning review using an animated SYNCHRO model when something remarkable happened. A mini-digger operator with 30 years’ experience sat in on the session. As Bowles ran through the construction sequence, the operator pointed at the screen. “He said: ‘Yeah, you can physically put me in that hole, but I’ll be in there for six months,’” Bowles recalls.

On paper, the plan looked fine. In practice, the Bobcat digger wouldn’t have had enough space to properly maneuver . The constraints would have turned a routine excavation into a months-long bottleneck—except that, crucially, this review was happening before construction materials had even been fabricated. “We took the issue straight to the engineers,” Bowles says. “They redesigned the shaft to remove the obstacles. We avoided six months of delays and saved roughly seven figures in costs—just by having the right person in the room, looking at the right model, at the right time.”

For Bowles, those “golden moments” of collaboration, as he calls them, are what make 4D modelling so powerful. Construction has long relied on fragmented information and century-old planning methods. “Henry Gantt died over a hundred years ago—but we’re still using Gantt charts to manage risk and time on projects,” says Bowles. “In the era of digital twins, this traditional approach is no longer sufficient.”

Pushing the Boundaries: 22 Bishopsgate

22 Bishopsgate, London, taking shape, alongside a snapshot of Freeform’s SYNCHRO 4D model.

22 Bishopsgate, London, taking shape, alongside a snapshot of Freeform’s SYNCHRO 4D model.As Freeform’s expertise grew, so did the ambition of its models. The Elizabeth Line work had demonstrated the power of digital planning, but in 2014 at 22 Bishopsgate—the second tallest building in the U.K.—they took things to a new level.

Multiplex, the construction firm leading the project, was highly technical and forward-thinking, says Bowles. “They had a first-class planning and BIM team, and they wanted us to use SYNCHRO to model everything: the initial demolition, the steel work, the frame, the slip core, and how the basement would integrate with the remnants of The Pinnacle, the abandoned skyscraper that once stood on-site.”

By rendering their SYNCHRO models using Unreal Engine and Unity game engines, Freeform enabled VR-headset experiences that let stakeholders step inside the digital construction site before a single beam was installed. The flexibility of VR also introduced new ways to experience scale. “We built in a function we called ‘Godzilla mode,’” Bowles says. “You could zoom out to the size of Godzilla and see the entire tower, with NatWest, the Gherkin, and the rest of the skyline around you. Then, using a hand controller to drop a pin, you could instantly shrink down and place yourself on, say, the 62nd floor at one-to-one scale, seeing the view of the river just as it would be in real life.”

The impact was huge. It stretched the capabilities of 4D modeling beyond scheduling and coordination, turning it into an interactive decision-making tool. This wasn’t just about building a better plan—it was about experiencing the construction process before it happened.

For Freeform, 22 Bishopsgate was a milestone. It wasn’t just their most comprehensive model to date—it was proof that VR and digital twins were transforming how the most advanced teams visualized and executed construction.

Jeddah Tower: Building the Future

Now, Freeform is tackling arguably its most ambitious project yet: Jeddah Tower in Saudi Arabia. When completed, at 1-kilometer tall, it will be the tallest building in the world—a structure that puts even the skyscrapers of Bowles’ youth in the shade.

The tower’s 167 floors and tapering, Y-shaped structure will ultimately weigh in at around a million tons. Coordinating its construction is a monumental challenge, requiring meticulous sequencing of materials, labor, and logistics across multiple international suppliers. “It’s a complicated, challenging, ambitious project, at the limit of what’s possible,” Bowles says.

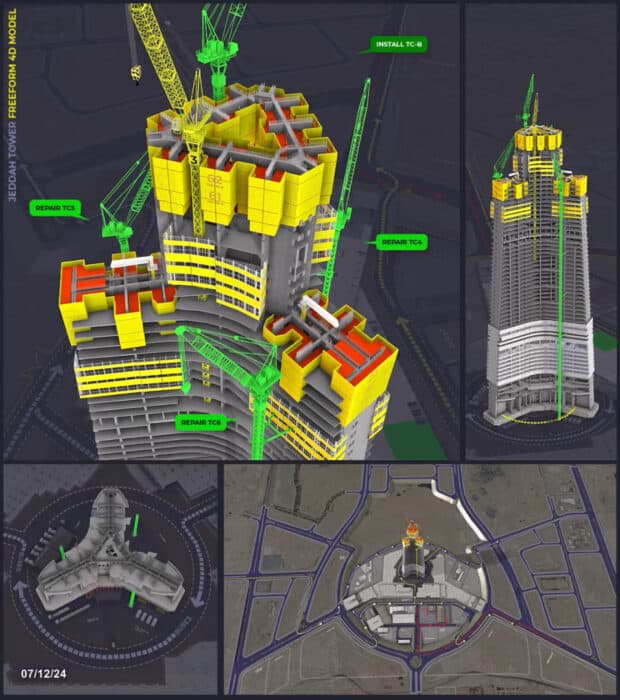

Digitally rehearsing the world’s tallest tower: Freeform uses SYNCHRO to plan every crane lift, concrete pour, and steel placement for the 1-kilometer-high Jeddah Tower—before it happens on site.

Digitally rehearsing the world’s tallest tower: Freeform uses SYNCHRO to plan every crane lift, concrete pour, and steel placement for the 1-kilometer-high Jeddah Tower—before it happens on site.Jeddah Tower has been under construction for years, but as the next phases ramp up, Freeform has been brought in to help optimize planning and execution with SYNCHRO. “We’ve digitally rehearsed, and rehearsed, and rehearsed every crane lift, every concrete pour, every steel placement—so when it happens on-site, there are no surprises,” Bowles explains.

“It’s all about collaboration and common ground,” he says. “If you build the models correctly and with enough content, there’s no room for interpretation: Everyone sees the same thing, knows the sequence, and understands exactly what’s coming next.”

This level of foresight is critical—not just for efficiency, but for safety. By identifying risks in the virtual model before crews ever step on site, the team can plan around potential hazards, reducing the chances of last-minute improvisation that could lead to accidents.

Jeddah Tower is more than another project for Bowles; it’s the ultimate skyscraper challenge, the kind of architectural ambition that first captured his young imagination. “This is Big Lego at the highest level,” he says.

Human Connection is Everything

For all its scale, the project is also a sign of how far construction has come—and where it’s heading next. Digital twins, 4D planning, and immersive simulations aren’t just innovations anymore; they’re shaping the future of how things get built.

Every major project is a series of thousands of decisions, each driven by the expertise of engineers, planners, and tradespeople. In the past, that siloed knowledge was scattered across spreadsheets and schedules. Now, the right tools bring it into focus—turning fragmented insights into a shared vision.

Bowles knows that software doesn’t build skyscrapers—people do. “I’ve been lucky to work with some amazing planners who understand that planning is a team sport. It’s not about creating a big schedule and just distributing it—it’s about getting the right people in the room and working through everything together.”