There’s no escaping the barrage of news related to climate change: deadly floods around the world; drought, famine and conflict in Africa; wildfires in Hawaii and Australia. Just last week, a series of storms slammed Dubai and drenched the desert metropolis with a year’s worth of rain in just 12 hours. In North America, the U.S. Global Change Research Program reported that “the effects of human-caused climate change are already far-reaching and worsening across every region of the United States.” Beyond the big headlines, human activities also endanger Earth’s biodiversity, with scientists warning that forests, soils and oceans will turn into “acoustic fossils,” unless humanity takes urgent action.

Earth Day 2024 takes aim at one of the main threats to biodiversity: plastics. In this year’s campaign, the environmental movement behind Earth Day is pushing for a 60% reduction in the production of plastics by 2040. Its Planet v. Plastics global theme for this year’s Earth Day is also raising awareness about the impact of plastics on “human, animal and all biodiversity’s health.”

While the industrial age has led to the rise in the Earth’s temperature, the latest digital technologies are also helping us reduce greenhouse gas emissions and prepare for the effects of climate change. Take a look at infrastructure, which includes essential systems like roads, bridges, transportation, and water and power distribution networks.

As an infrastructure engineering software company, Bentley Systems released its Environmental and Social Governance Report (ESG) on Earth Day. It illustrates how infrastructure engineering firms, builders, owners and operators around the world are using Bentley technology like digital twins to minimize their environmental impact and improve the world’s infrastructure and make it more resilient. Angela Curry, Bentley vice president and chief compliance officer, and Chris Bradshaw, the company’s first chief sustainability officer, write in their Earth Day note, that “with climate change and other social and environmental challenges straining the world’s aging infrastructure,” it is more important than ever for companies like Bentley to provide the technological solutions that help engineers, builders, owners, architects, geologist and other infrastructure professionals design, build, and operate infrastructure that is more sustainable and resilient.

Take a look at five recent examples:

Notes from the underground

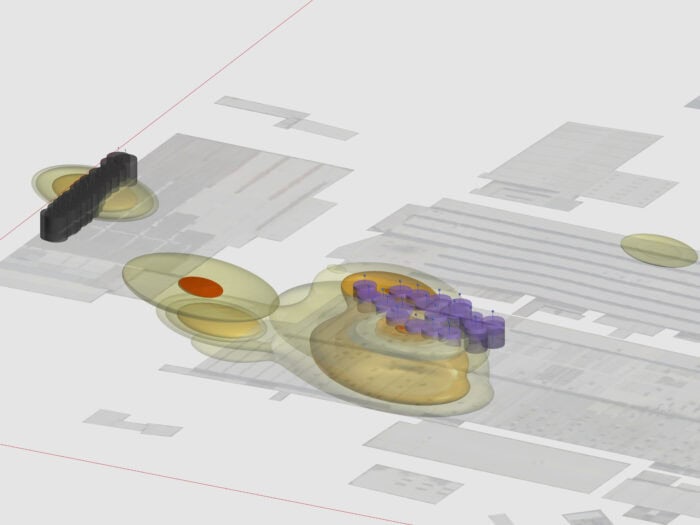

In Brazil, the environmental services company Geoambiente S.A. used technology developed by Seequent, the Bentley subsurface company, to restore a vital water ecosystem at a sprawling, 116,000-square-meter industrial complex. Since the 1970s, the complex has manufactured machinery and vehicles for the South American country’s giant agricultural sector. Decades of heavy-duty industrial processes such as machining, tooling, and painting were polluting the local area with organochlorine and hydrocarbon compounds. Environmental inspectors were even finding plumes of contaminants in the underground layers of permeable rock that are a source of drinking water for local communities. The manufacturer hired Geoambiente to fix the issue, but the company couldn’t complete the job without understanding the source, entry point and extent of the pollution.

Geoambiente worked with Bentley to build a digital hydrogeological model of the entire area. The solution converts complex data into clear, easy-to-interpret visualizations that allow users to gauge the source and mass of the contaminants, and identify how they travel and where they get trapped. Using these underground insights, the manufacturer placed absorptive barriers in areas with the highest concentration of contaminants. Within six months, the solution significantly reduced contaminant levels, including a complete elimination of dichloroethylene and vinyl chloride, a 99% reduction in benzene levels and a 72% reduction in trichloroethylene. The result is cleaner aquifers and safer drinking water for local communities.

The solution allowed Geoambiente to gauge the source and mass of the contaminants, and identify how they travel and where they get trapped.

The solution allowed Geoambiente to gauge the source and mass of the contaminants, and identify how they travel and where they get trapped.Treading lightly in Sweden

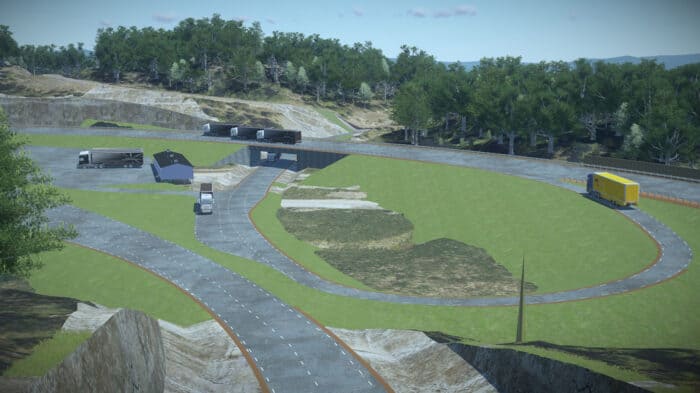

When the truck manufacturer SCANIA wanted to build a new track to test drive its electric and autonomous vehicles, it also wanted to limit the track’s environmental impact. This test track was no simple loop: SCANIA required 19 kilometers of roads, with 60 intersections and junctions through complex, hilly terrain. It engaged the engineering consultant AFRY whose engineers knew they needed a flexible, accessible design environment, not least because changing any single aspect of the track would impact numerous other elements. Engineers used Bentley’s software to model the track. The software’s digital model, fed with mountains of project data, didn’t just slash the time engineers spent designing the track, it also generated important insights about the impact of the design on the environment. This allowed engineers to minimize earthworks and reduce the footprint of the test track. In the long run, the track will be vital to the development of emissions-free vehicle technology.

The digital solution allowed AFRY engineers to minimize earthworks and reduce the footprint of the test track.

The digital solution allowed AFRY engineers to minimize earthworks and reduce the footprint of the test track.The data engine that could

Similar techniques are also helping to minimize the land and carbon footprints of High Speed 2 (HS2), a highspeed railway being built in the U.K. The first phase of the huge mass transit project literally required moving mountains, with approximately 25 million cubic meters of material – about 440,000 40-foot shipping containers – earmarked for excavation. The project developers had also pledged to minimize their carbon emissions and committed to no net loss of biodiversity. They knew they could slash the emissions produced by their trucks if they could identify how to reuse material and minimize waste during the earthworks. However, traditional geotechnical assessment methods were not up to the task. So HS2 developers turned to Mott MacDonald, an engineering consultancy. Mott MacDonald used advanced digital data management and geotechnical applications developed by Bentley and Seequent software to create a collaborative digital assessment technique based on a 3D representation of the construction site. This gave developers a wealth of insights about material reuse across the project, enabling a large reduction in waste and emissions.

Bentley and Seequent software gave developers a wealth of insights about material reuse across the HS2 project, enabling a large reduction in waste and emissions.

Bentley and Seequent software gave developers a wealth of insights about material reuse across the HS2 project, enabling a large reduction in waste and emissions.Virtuous circularity in Japan

Bentley technology also helped reduce plastic waste in Japan. The developers of the MARUI recycling plant, designed to convert used plastic bottles into food-grade recycled products that can be used as food containers, were seeking to ensure an efficient build of their project and maximize productivity of its operations. They turned to Swiss consultant Polymetrix, which used Bentley applications to create a connected digital environment that allowed all parties to clearly track progress. This allowed MARUI’s developers to complete their facility around 5-10% faster than similar projects, and they achieved resource productivity approximately 10-20% higher than the norm. This will help reduce plastic waste and extend the lifetime of the synthetic materials in Japan.

The MARUI plant will help reduce plastic waste and extend the lifetime of the synthetic materials in Japan.

The MARUI plant will help reduce plastic waste and extend the lifetime of the synthetic materials in Japan.Going digital Down Under

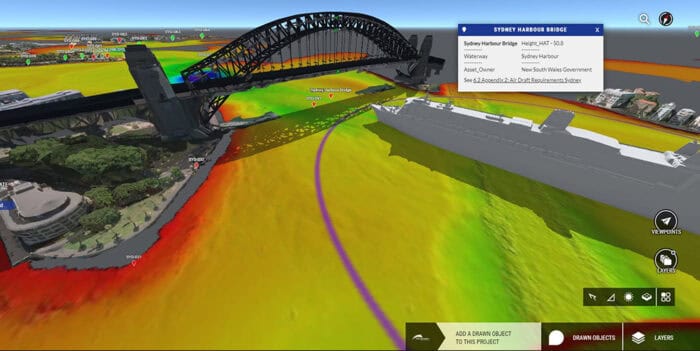

It wasn’t so long ago that the Port Authority of New South Wales, which oversees numerous seaports along the southeastern coast of Australia, lived in a 2D world. They managed their coastal assets using static plans and maps. This made it difficult to get a comprehensive picture of all their facilities and drill down into details. Now Bentley applications are allowing them to create state-of-the-art models crunching a wealth of detailed environmental and engineering data. They combine these models with high-definition images of their facilities to create connected digital twins. The twins and their sophisticated visualizations reduce the need for site visits and improve both safety and ocean ecosystem health. This allows for sustainable development of the “blue” economy.

Bentley digital twins and their sophisticated visualizations reduce the need for site visits and improve both safety and ocean ecosystem health.

Bentley digital twins and their sophisticated visualizations reduce the need for site visits and improve both safety and ocean ecosystem health.Learn more about the ways Bentley is empowering users to support United Nations Sustainable Development Goals and to protect the world’s biodiversity.

Chris Noon is a freelance business reporter and foreign correspondent. He writes about energy, sustainability, and industry.