In 1985, Back to the Future’s Marty McFly told movie-goers, “If you put your mind to it, you can accomplish anything.”

The same can be said for any field, but especially construction, where the obstacles can seem insurmountable.

Major construction projects require countless resources—from equipment to field personnel—that then generate large volumes of data, making the sharing of construction models historically difficult. Without an accessible way to share information, teams face collaboration obstacles, lack of skills, and budgetary issues that have slowed a unified, effective approach to industrywide construction digitalization.

Many contractors use 4D models to plan the sequence of work. But what if, instead of reverting to traditional ways, including 2D paper plans and Gannt charts, for execution, the industry put its mind to using 4D models throughout the entire construction phase?

What Is 4D Construction Modeling?

According to the Department of Transportation, a 4D model combines a 3D model with a project schedule to create a simulation of construction activities. At Bentley, we take that definition a step further, defining 4D construction modeling as the breaking down a design model into constructible components to add the element of time to a 3D model to simulate and optimize construction sequencing, site logistics, and resource planning.

The important difference is the ability to break down a design model into constructible components. These components enable precise scheduling, optimizing resources. Meanwhile, field access to 4D models improves productivity and connects the office and field.

Adding the element of time to a 3D construction model can help construction firms and owners from pre-planning to delivery. The 4D construction model allows for more accurate quantity take-offs, leading to more accurate bidding. Not only can firms provide a visual representation of the plan that everyone can understand, but they can also show how the project will progress over time. It can be used to keeping stakeholders and the public informed.

While 2D plans and Gantt charts have their uses, converting models back to them can make the workflow more complicated. Without the technology to digitalize and visually plan projects before construction begins—and sync the model to the schedule to see the project’s progress over time—there is an increased chance of risk, costly rework, and workspace and logistical clashes. These issues can delay project delivery and overextend the budget. They also do not provide the opportunity to break the design down into constructible components. 4D construction modeling transforms workflows—such as resource tracking, inspections, work package planning, and project management—to deliver projects timely and more profitably.

Meeting Deadlines with Better Insights

Our users have shown that scheduling and simulations with 4D construction digital twins can reduce costs, increase field labor productivity, and reduce overall schedule time, industrializing delivery of construction projects.

Take, for example, ACCIONA.

As part of Melbourne’s level crossing removal initiative, an AUD 744 million project was deployed to remove 20 level crossings and construct 13 new stations along the Frankston Line. ACCIONA needed to upgrade their digital approach to a more seamless integrated solution, as their previous strategy lacked context, connectedness, and did not visually communicate the construction sequence.

Ultimately, the 4D construction model played a key role in helping ACCIONA deliver the project on time with minimal disruption to the public, reducing staging time by 67% and drafting requests by 88%.

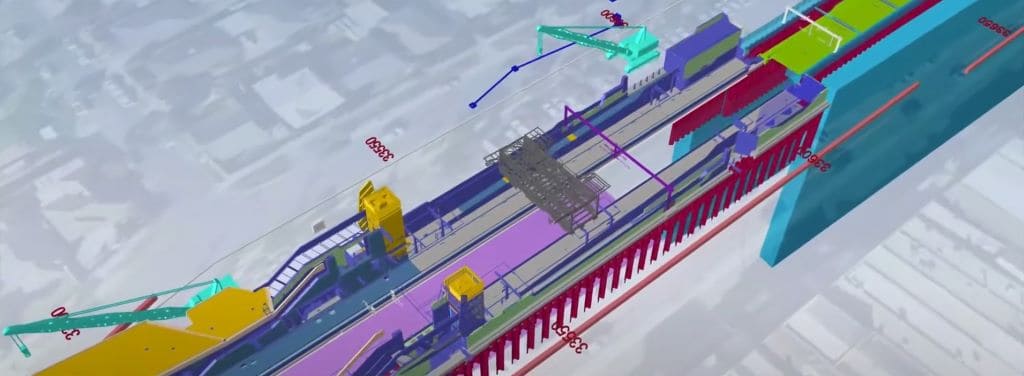

ACCIONA used the 4D construction model to provide the construction team the information that they needed to optimize decision making on the job site. Image courtesy of ACCIONA.

ACCIONA used the 4D construction model to provide the construction team the information that they needed to optimize decision making on the job site. Image courtesy of ACCIONA.The Future Isn’t Written and Can Be Changed

With 4D construction modeling, Skanska was able to drive a “one team” approach in their work to install two bridges. Image courtesy of Skanska.

With 4D construction modeling, Skanska was able to drive a “one team” approach in their work to install two bridges. Image courtesy of Skanska.Working in a live virtual construction environment provides a single source of truth, ensuring clearer project alignment and better decision-making. This instant data-sharing capability among teams and stakeholders increases productivity, enhances communication, optimizes resources, and provides improved project controls and visibility.

One organization that is taking advantage of these capabilities is Skanska.

When they were chosen by National Highways to install two bridges as part of an improvement project on the U.K.’s busy M42 motorway, engineers at Skanska performed digital rehearsals of the intricate operation. Utilizing 4D construction software, these digital rehearsals allowed the team to make changes to the project and see how it would affect the outcome, conducting construction in the most efficient way. The application enabled the project team to digitally rehearse the construction sequence multiple times before building the asset.

Skanska’s success relied on unifying the delivery team, supply chain, and external stakeholders around a single source of project truth. Everyone could clearly understand the construction methodology and how each individual role fits into the wider operation. With 4D construction modeling, Skanska was able to drive a “one team” approach, where all key project members could input, share, and learn around a 4D digital model, driving better decision-making and a more cohesive, transparent, and collaborative environment.

Back to the Future—and It’s 4D

Back to the Future’s other lead character, Dr. Emmett Brown—or “Doc” as he’s usually called—told movie-goers, “Roads? Where we’re going, we don’t need roads.”

While that was true for Doc and Marty McFly as they drove the DeLorean through time, we still need roads—and many other types of infrastructure.

It’s been traditionally thought that the construction industry has lagged behind other infrastructure sectors when it comes to technology. However, ACCIONA and Skanska have proven that construction firms and owner-operators are embracing technology to gain insights into project timelines, cost and risk, and collaboration methods.

By adopting the right technologies, the construction industry can see considerable transformation in the supply chain—with improved timeliness, efficiency, and transparency. 4D construction modeling streamlines construction project management processes and reduces waste. It lowers barriers to productivity and can reduce project costs and durations by double-digit percentages.

As Andy Kaiyala, WSB’s vice president of construction technology and controls, said in an interview on the Peggy Smedley Show, “We’re at right moment in time as an industry to embrace the opportunity, to really move past thinking of it in terms of risks, and thinking of it in terms of opportunity. That this digital future is coming. Do I want to be part of that future now, preparing my business, preparing my people, and really leveraging the opportunity to be more competitive, to mitigate risk, to have better transparency. Do I want those things? I think the answer is going to be yes for a lot of companies.”

The future of construction lies in embracing this cutting-edge technology solution that is now driving construction industry planning practices and initiatives to implement modern, more certain, and more sustainable construction methods. With a powerful digital construction platform, such as SYNCHRO, Bentley’s construction management software, the heavy civil industry can unlock the true value of the 4D model and get time on their side as it transforms into a construction digital twin, connected to real-time project data that enables construction teams to work faster, better, and safer.

After all, like Doc said, “Your future is whatever you make it, so make it a good one.”