A digital twin is best described as a living representation of something. If the something was me, it would have my dimensions, eye color, standing heart rate, medical history, and importantly it would look like me. As it’s living – it would age with me, show that I now wear glasses, would signal that I’d better do something about my cholesterol, and it could show me how I’d look in a new suit (not bad as it turns out).

In the world of infrastructure, the living aspect of a digital twin is greatly understated. The insights from one live source of truth increases construction efficiency throughout operations. With live data from IoT sensors, project stakeholders using digital twins can make good, fast decisions in real time. Risks to life are decreased with consequence-free scenario modeling, and with a living digital representation of your project, smarter, more sustainable workflows give you a significant competitive advantage.

It’s over 30 years since the term ‘BIM’ (Building Information Modeling) emerged and the construction industry grabbed it with both hands. Designers proudly showed off their projects as wireframe representations with foundation elements happily floating in space.

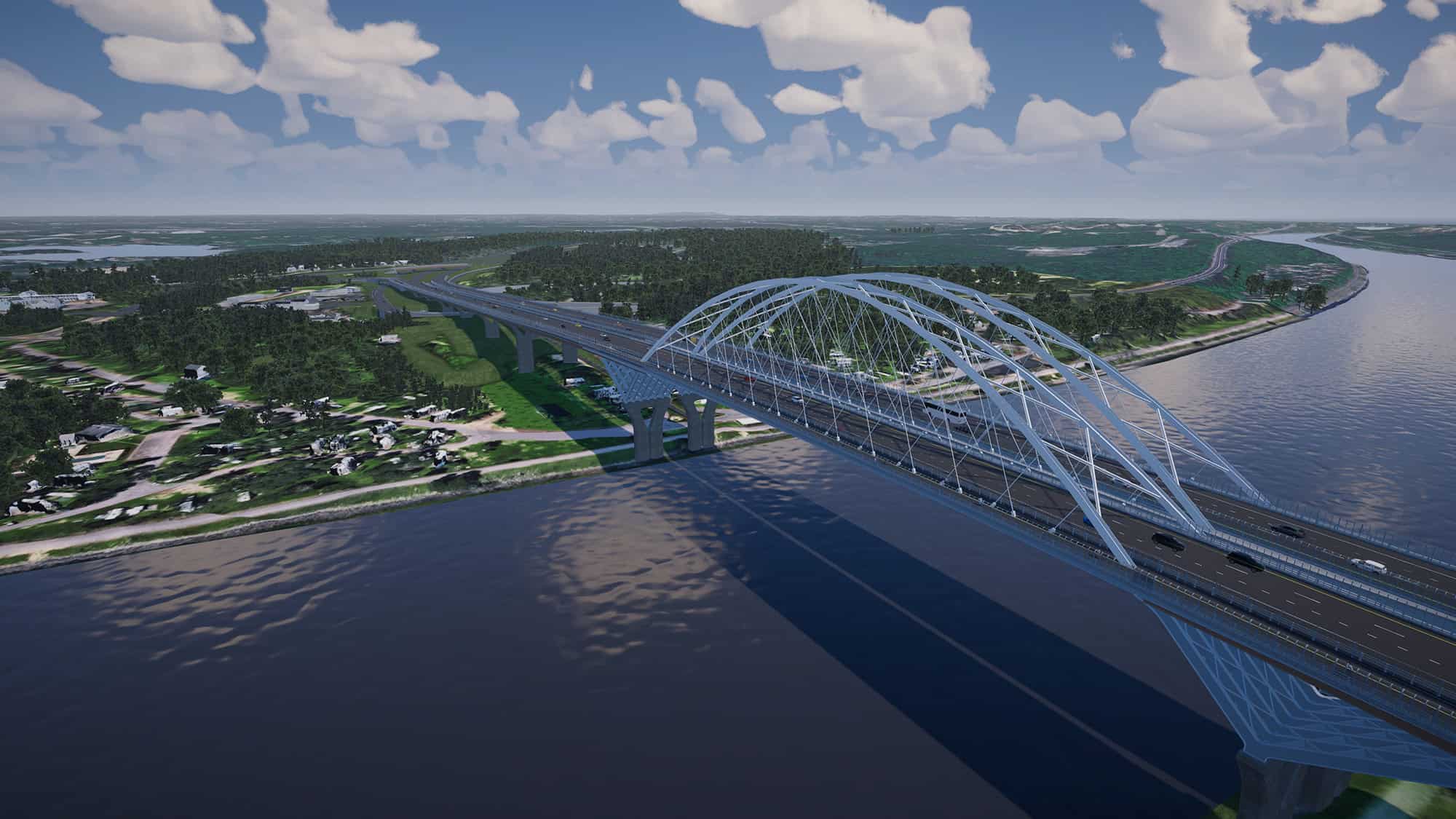

Digital twins in construction have been a natural evolution. It is brought to life with data from multiple sources, including drawings, specifications, documents, analytical models, photos, reality meshes, and BIM models. The digital twin seamlessly integrates with ground models so, at last, we can connect the engineers and the geoscientists. And the Internet of Things (IoT) feeds in live data, including traffic flows, wind, lighting, and the surrounding natural environments. Project visualizations using digital twins in construction are therefore realistic. No wonder my digital twin looks like me.

Digital Twin vs. BIM

The early adopters of digital twins in construction have had a competitive edge for a while now (more on that later). But I read that half the major civil engineers and contractors outside the U.S. are using reality capture, model-driven jobsite automation, and digital twins (from a recent survey by Dodge Data and Analytics). Yet in the U.S. this survey showed just 30%.

A MarketsandMarkets report estimated that the global digital twin market will grow from around $3 billion (2020) to $48 billion (2026), with an average compound annual growth rate of 58%. It seems clear to me that this wagon is picking up speed and I think it’s a very short time before migration toward digital solutions will be both vital and inevitable. Fortunately, companies that are already implementing BIM workflows will likely find the transition to digital twins easier. Seems a good time to get on board.

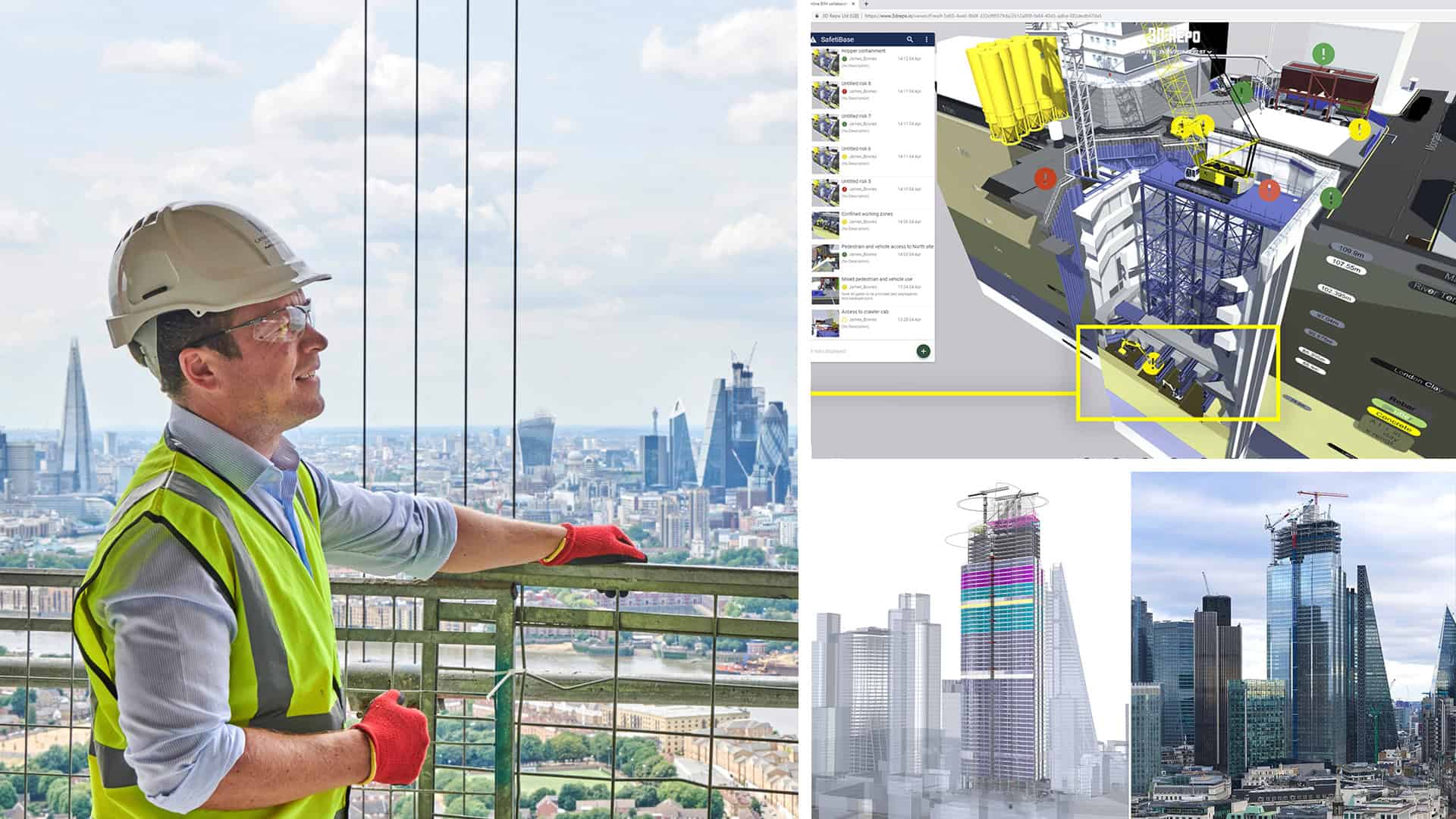

Coming back to that competitive edge I spoke of earlier. The benefits of the digital twins are compelling. Let’s start with the data. With a large capital construction project generating millions of records, a cloud-hosted digital twin makes the latest information available to any member of the team, saving time and avoiding data source errors.

Not only does it connect all the data for the various disciplines involved in a construction project, but it also connects the people making the decisions. This enables the transformation of workflows, allowing safe and efficient scenario testing, and real-time progress tracking from the field.

The many field workers that operate heavy equipment on site stay on the same page with execution workflows originating from one source of truth, with instructions sent to their hand-held devices. Teams can leverage the digital twin to access and capture real-time compliance and performance tasks or data to make better, faster decisions that keep projects in control in terms of cost, schedule, quality, and safety. For heavy civil projects, details such as road grades and drainage can be analyzed in the design stage for any possible issues, and corrections can be made and synced instantaneously.

Digital twins in construction connect both data and people from across disciplines.

Digital twins in construction connect both data and people from across disciplines.Additional environmental conditions – such as lighting, traffic flow, accessibility, and even wind speed and direction – can be evaluated to gain insight and provide a detailed view of how the constructed model may look and perform. These insights allow project teams to make data-driven decisions and, therefore, predictable outcomes on key performance indicators.

Because the digital twin is constantly synced in real-time, project managers can monitor progress against a schedule created using 4-D modeling, foreseeing possible issues that could cause construction delays and mitigating them before they happen. They can make sure that machinery is in the correct location at the correct time, coordinating material delivery. The prevention of such delays can significantly prevent cost overruns.

So, those predicted growth rates for the digital transition in construction did not surprise me.

I am also excited to see the digital offering is constantly expanding and evolving.

Reality modeling

Bentley’s iTwin, as a base model, is seeing many high-value add-ons emerge. The reality capture tool LumenRT creates visualizations and simulations from the iTwin, rather than do this as a separate process. No need to commission those expensive, one-off explainer videos anymore! Critically, LumenRT integrates with the digital twin to create interactive animations and simulations which are constantly being updated.

Another high-value add-on is a media indexing service included with SYNCHRO Control. This leverages artificial intelligence and machine learning to index all job site photos. Photos are indexed by their geospatial location (date and time), their context (typo of photo description), and creates a custom-trained construction classification of the photo’s contents. As a result, users can search for any text in a photo, such as equipment tag or photo objects like cranes, grade stakes, traffic cones, or utility covers.

Digital Twins delve into emerging IoT technologies, using sensors, smart devices, site cameras, and driverless vehicles to collect data from physical locations. Point clouds from drone surveys, flown a day apart, can quickly compute information, such as earthwork volumes or daily site progress. More data than ever before is turned into valuable site information and the digital twin keeps evolving as a living representation of the project.

Initiating digital twins in construction

With construction complete, data flows between the digital twin and its physical counterpart to increase efficiency of the ongoing operation and maintenance of the asset.

With construction complete, data flows between the digital twin and its physical counterpart to increase efficiency of the ongoing operation and maintenance of the asset.Once a project is fully constructed and operational, the digital twin is an as-built model for the owner/operator. There is a bi-directional flow of data between the digital twin and its physical counterpart, using IoT data points to provide real-time analysis on system performances. These analyses are then used to increase efficiencies in the ongoing operation and maintenance of the asset.

So how do you get started with a digital twin? Designers can be confident that the twin will incorporate all elements of the technology stack, including geospatial and geotechnical data, photos, 2-D and 3-D design files, BIM model specifications, and reality modeling data. It takes it all in, and with it in the cloud, a project can be tracked, analyzed, visualized, and collaborated on by all parties with a vested interest – right from kick-off.

In the world of construction, the living aspect of a digital twin is creating a competitive edge. I see those with realistic digital representations of their projects, bringing them to life to enable smarter, more sustainable decisions. It’s clear to me that the benefits are significant and that the forecasters are right: The use of digital twins in construction is both vital and inevitable.