For years, digital transformation in mining felt like something that was always just around the corner. Leaders talked about it, vendors promoted it, and teams experimented with it. But widespread adoption always seemed just out of reach.

That’s no longer the case.

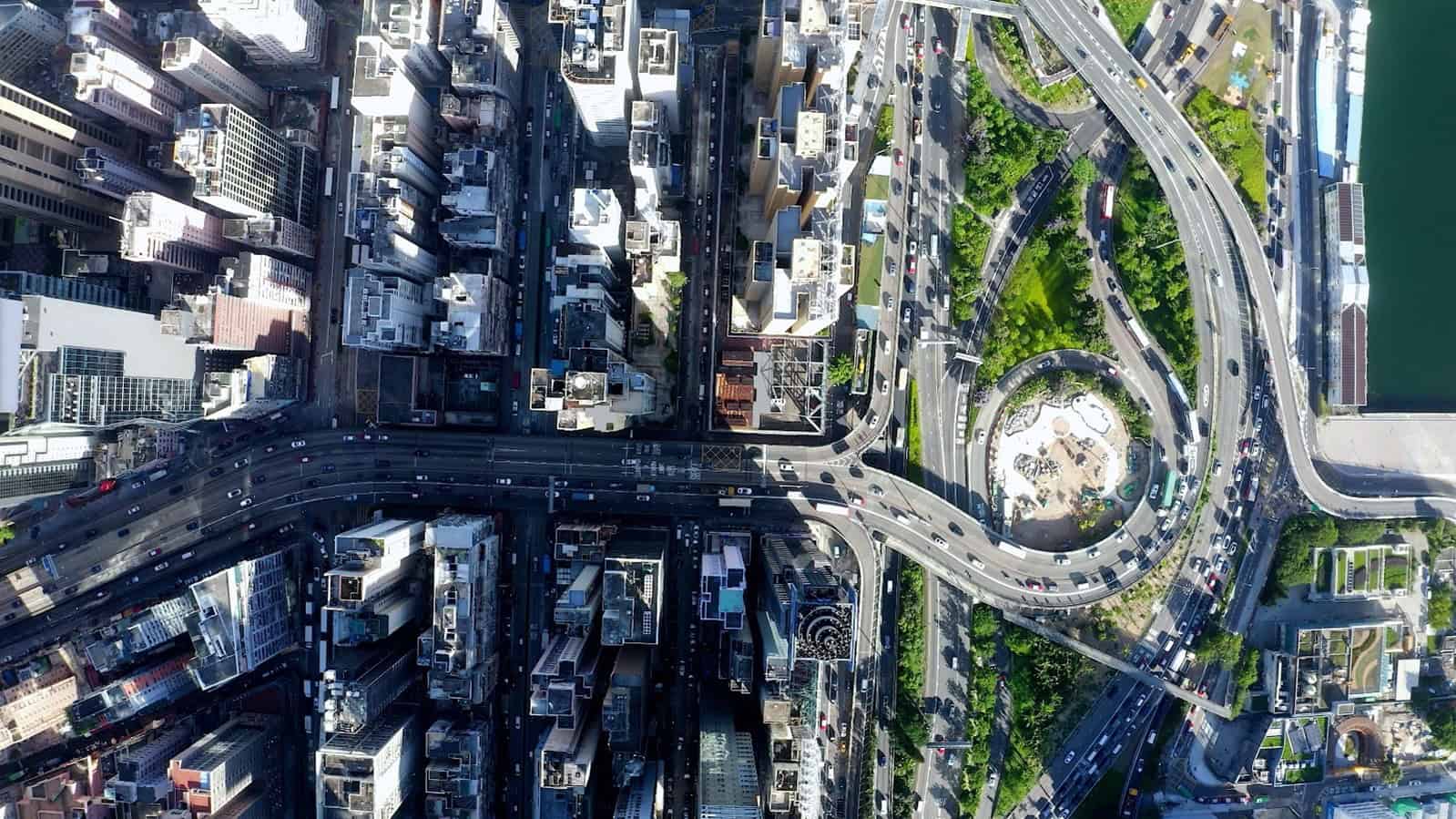

Walk onto any modern mine site today, and you’ll see IoT sensors quietly collecting thousands of data points, dashboards displaying real-time operational insights, and engineers comparing on-the-ground conditions with digital models. Mining is becoming smarter, faster, and more connected.

But here’s the challenge: visibility alone isn’t enough. Data often lives in silos—spread across IoT sensors, models, and reports—making it hard for teams to turn information into confident, timely decisions.

This is where digital twins come in. Once considered a futuristic concept, digital twins have become a practical foundation for modern mining operations, enabling organizations to connect data streams, improve collaboration, and manage risk in real time.

Bentley’s new e-book, Coming of Age: How Digital Twin Technology Is Changing the Face of Mining, explores these changes. In this blog, we’ll offer a first look at industry research, trends, and examples that show how mining organizations are unlocking the full potential of both their IoT data and digital twins.

Why mining operations need modern tools and real-time data

Mining has always been a high-stakes industry where precision matters and conditions can shift fast. But in recent years, the pressure on operators has grown. Companies now face:

- Increasing expectations around decarbonization.

- Stricter environmental reporting.

- Aging infrastructure.

- Rising demand for critical minerals such as copper, lithium, and rare earths.

Society relies on these materials to power clean energy and digital technologies while also expecting mining organizations to operate more safely, transparently, and sustainably.

Meeting these expectations requires clearer insight into assets, faster decision-making, and stronger coordination across teams. This has accelerated the adoption of digital twins and automated monitoring systems. Each delivers clear value, helping organizations manage risk in complex, fast-changing environments.

What is a digital twin in mining and why does it matter?

A digital twin is a detailed virtual representation of a physical asset or environment. In mining, a digital twin often depicts a full replica of a mine site or a high-risk structure, such as a pit wall, underground excavation, or tailings storage facility.

By combining engineering designs, geological models, geometry, and inspection data into a single model, teams can understand:

- How the mine or asset was built, using engineering design, construction records, and subsurface models.

- How it is expected to perform, based on simulations and historical benchmarks.

- How real-world conditions are changing through live data from IoT sensors and inspections.

This shared reference point reduces ambiguity, strengthens communication, and improves collaboration across disciplines. Engineers can test scenarios, planners can assess risk in context, and field teams can access accurate information without digging through disconnected reports.

In practice, digital twins support safer planning, tighter coordination, and more confident decisions—critical advantages in an industry where uncertainty is constant.

Digital twin adoption in mining is surging—here’s why

While the concept of digital twins has been around for years, their real-world application in mining is rapidly accelerating.

According to a recent survey:

- 58% of mining organizations have already implemented digital twins and are achieving results.

- An additional 30% are actively implementing digital twin projects right now.

- Together, nearly nine out of 10 mining organizations are using, piloting, or planning digital twin initiatives.

And it’s not just about adoption rates. Survey respondents overwhelmingly recognize the potential value of digital twins for their organizations, with 88% rating their potential impact as high or very high. Many also point to the growing importance of connecting these models to live data sources to fully realize that value.

Why digital twins align with mining’s top priorities

Survey respondents cite clear reasons for adopting digital twins. These tools help teams plan, coordinate, and evaluate risk more effectively by bringing design, geometry, and operational context together.

Organizations report measurable impact in areas that include:

- Health and safety

- Energy efficiency and decarbonization

- Infrastructure oversight

- Mine planning and risk assessment

By providing a consistent, shared view of complex assets, digital twins are becoming one of the most practical ways to modernize collaboration and decision-making.

But as mines collect increasing amounts of automated monitor ing data, teams are beginning to ask a new question: what if digital twins could reflect conditions in real time?

Real-time IoT sensor data meets the digital twin

Automated monitoring is now a standard feature of modern mining. IoT sensors track parameters—such as slope movement, pore pressure, and environmental conditions—around the clock.

Industry trends highlight this growth:

- 72% of condition monitoring data is already collected automatically.

- This number is expected to rise to 80% within two years.

- 82% of mine owners say automated condition monitoring helps them deliver projects more cost-effectively.

- 76% say automated monitoring opens new market opportunities.

But collecting data is only the beginning. The real breakthrough occurs when these live streams feed directly into a digital twin. When connected:

- Models become dynamic, reflecting changing conditions continuously.

- Alerts trigger automatically when thresholds are exceeded.

- Engineers view risk in context and coordinate responses faster.

In this connected ecosystem, the digital twin becomes more than a model; it becomes an operational hub.

Evergreen digital twins: Real-time mining visibility and control

Standard digital twins have long played an important role in mining. Evergreen digital twins build on this foundation and take it a step further by integrating real-time IoT data. They evolve alongside the asset, providing an always-current view that enables teams to:

- Detect early warning signs of movement or instability.

- Trigger automatic alerts.

- Track environmental indicators accurately.

- Maintain audit-ready, time-stamped records.

- Respond more quickly to weather or operational events.

- Move from reactive to predictive maintenance.

Platforms such as Bentley’s iTwin IoT make these benefits possible by bringing live sensor data into a single environment with a digital twin view. The result is a clear, up-to-date view into a complex site, supporting safer and more confident operations.

Real-world impact: OceanaGold’s Waihi Mine

A clear example comes from OceanaGold’s Waihi Mine in New Zealand. Like many operations, Waihi struggled with fragmented datasets: geological models, geotechnical records, and real-time piezometer readings were spread across multiple systems, complicating risk assessment for its tailings storage facilities.

To address this, the team implemented an integrated digital twin solution using software from Bentley and Seequent, The Bentley Subsurface Company, including Seequent Central, Leapfrog Geo, GeoStudio, and iTwin IoT.

The result was a cloud-based, 3D digital twin that unified real-time sensor data with geological and operational information. This enabled proactive, visual monitoring of slope stability and asset performance, especially during high-risk events like heavy rainfall.

The project delivered tangible benefits:

- Faster response to operational triggers.

- Streamlined audit and compliance reporting.

- Enhanced collaboration among engineers, geologists, and operational teams.

- A shift from reactive to proactive tailings storage facility management.

And this is just one example of how evergreen digital twins are improving safety, resilience, and decision-making across mining.

Explore the full mining e-book on digital twins and IoT

This blog only scratches the surface of the research, examples, and insights included in the full report. For a deeper look at what mining leaders are prioritizing, how digital twins are being applied across planning and operations, and how automated monitoring systems are reshaping risk management, you can read the complimentary e-book Coming of Age: How Digital Twin Technology Is Changing the Face of Mining.

If you’d like to understand how these ideas come together in a live, continuously updated environment, learn more about iTwin IoT, Bentley’s platform for connecting real-time sensor data with digital twins.

And if you’re interested in seeing an evergreen digital twin in action, you can schedule a demo with our team to explore how the approach fits your own assets and workflows.