RDF Jakarta Plant

Organization: PT Wijaya Karya

Project Name: Rotoran Jakarta Refuse-Derived Fuel (RDF) Plant

Location: Rorotan, Indonesia

Project Phase: Final Stages of Construction

Expected Completion Date: November 2025

Estimated Project Cost: IDR 1.28 Trillion (Indonesian Rupiah)

Bentley Software: AutoPIPE, STAAD, iTwin Capture, iTwin IoT, MicroStation, OpenPlant, ProjectWise, ProStructures, SYNCHRO

Additional Context: PT Wijaya Karya (WIKA) delivered the world’s largest refuse-derived fuel facility in Jakarta, Indonesia, converting up to 2,500 tons of municipal waste daily into sustainable fuel, significantly reducing landfill overflow, carbon emissions, and project costs through advanced digital construction management and Bentley software integration.

Project

The RDF Jakarta Plant, located in Rorotan, Indonesia, is the world’s largest refuse-derived fuel facility. It is designed to convert up to 2,500 tons of municipal waste daily into a fuel source that is a sustainable alternative to coal. Developed by state-owned engineering firm PT Wijaya Karya (also known as WIKA) and Jaya Konstruksi, it tackles Jakarta’s severe landfill overflow and rising waste management costs. By diverting waste from conventional processing sites, the plant lowers greenhouse gas emissions and promotes a circular economy.

WIKA led the project using their expertise in digital construction management and green engineering solutions to manage planning, design, construction, commissioning, and operational intelligence.

Facts

The new plant:

- Diverted 30% of municipal waste from landfills, cutting over 100,000 tons of carbon dioxide emissions annually.

- Reduced the city’s carbon footprint equivalent to 280,000 barrels of oil per year by producing 875 tons of refuse-derived fuel daily.

- Created over 250 new local jobs and stimulated secondary economic activity.

- Enhanced urban sanitation and reduced odour through advanced waste treatment.

By going digital with Bentley solutions, WIKA:

- Saved approximately 52,000 project work hours.

- Improved engineering productivity by 40%.

- Achieved a 15% reduction in overall project costs.

- Achieved a 20% higher project ROI compared to existing methods.

"The integration of Bentley’s digital solutions was critical to the success of the RDF Jakarta project. Bentley technology empowered us to deliver the world’s largest RDF facility, setting a new benchmark for circular economy projects in Southeast Asia."

Octob Bhayu Hanggoro Putro, VDC Coordinator, PT Wijaya Karya

Solution

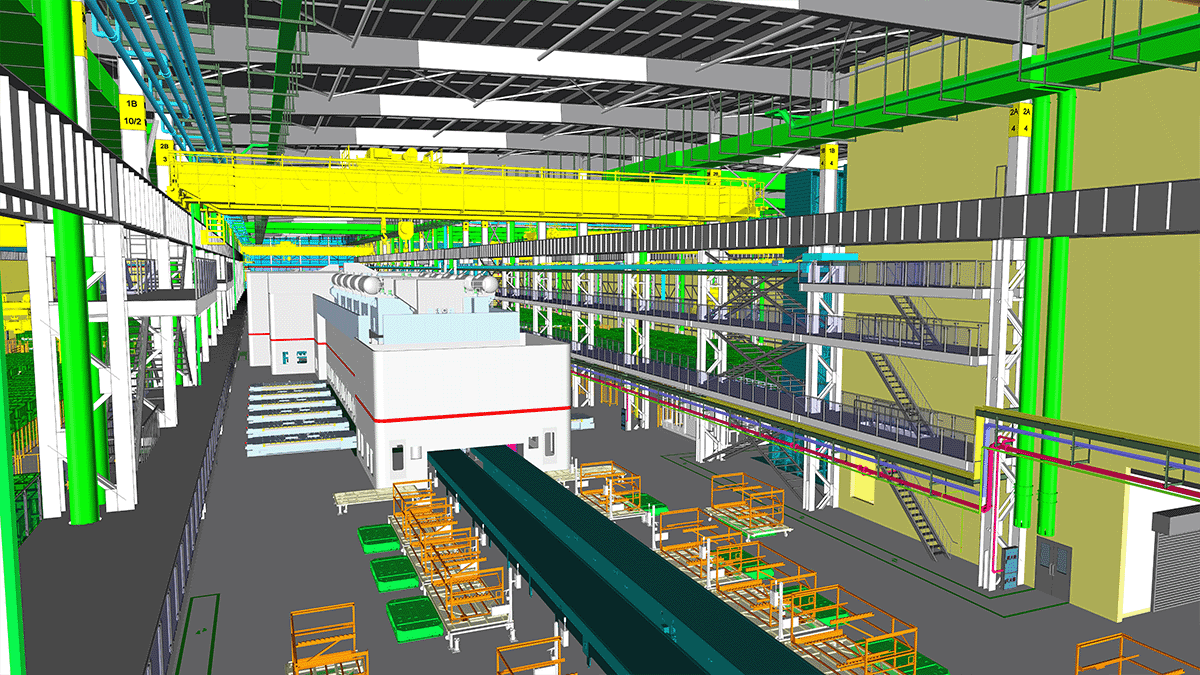

WIKA implemented a comprehensive, digitally integrated approach to successfully deliver this project. They adopted advanced digital workflows to optimize resources and ensure sustainability. Faced with complex interdisciplinary coordination across the engineering, procurement, and construction phases, the team deployed a wide selection of Bentley’s comprehensive portfolio. They used SYNCHRO, MicroStation, OpenPlant, ProjectWise, and ProStructures, which were all integrated to overcome existing fragmented workflows and data silos. This transformative approach enabled real-time 3D modelling, advanced clash detection, 4D construction sequencing, and 5D cost management, significantly improving project precision, reducing waste, and accelerating delivery.

Bentley’s solutions were chosen for their ability to integrate complex project workflows. They formed the digital backbone for the project, supporting seamless collaboration among multidisciplinary teams and external contractors.

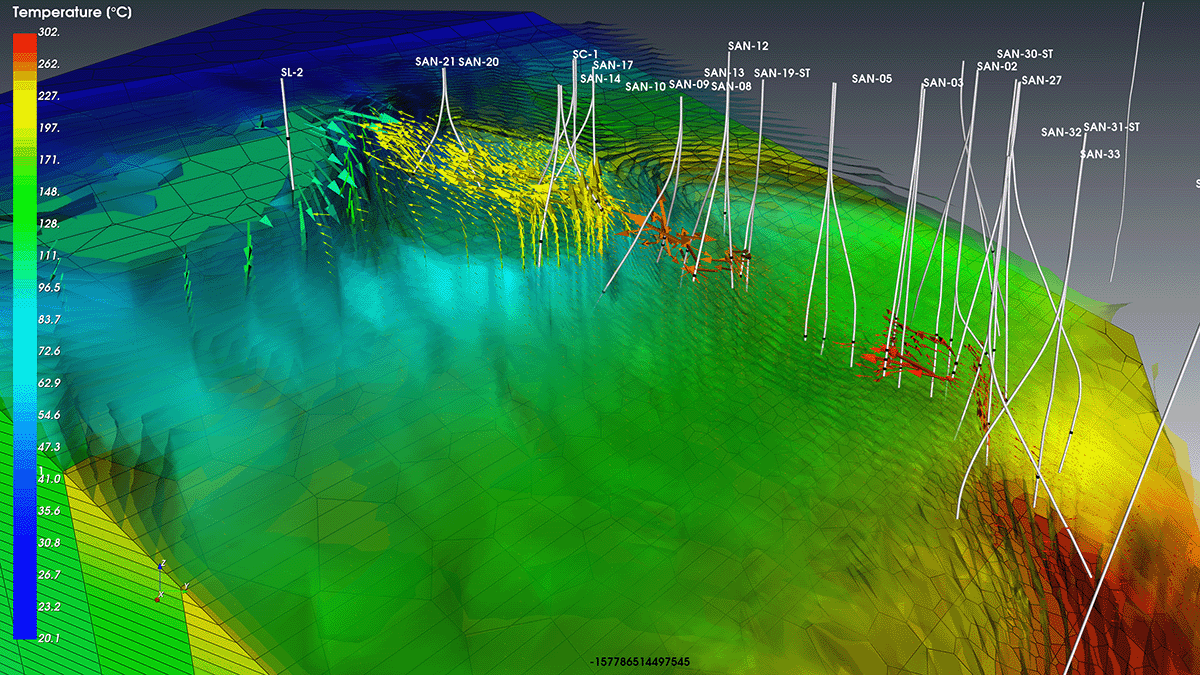

WIKA adopted a digital approach to achieve robust project management, centralized document control, and dynamic collaboration across civil, structural, mechanical, and environmental teams. They addressed complex site conditions, notably unstable soft soils, with innovative engineering, using slab-on-pile foundations modelled via Bentley PLAXIS. AI-driven features in Bentley’s platforms supported real-time anomaly detection, predictive sequencing, and automated validation, further enhancing efficiency and risk mitigation.

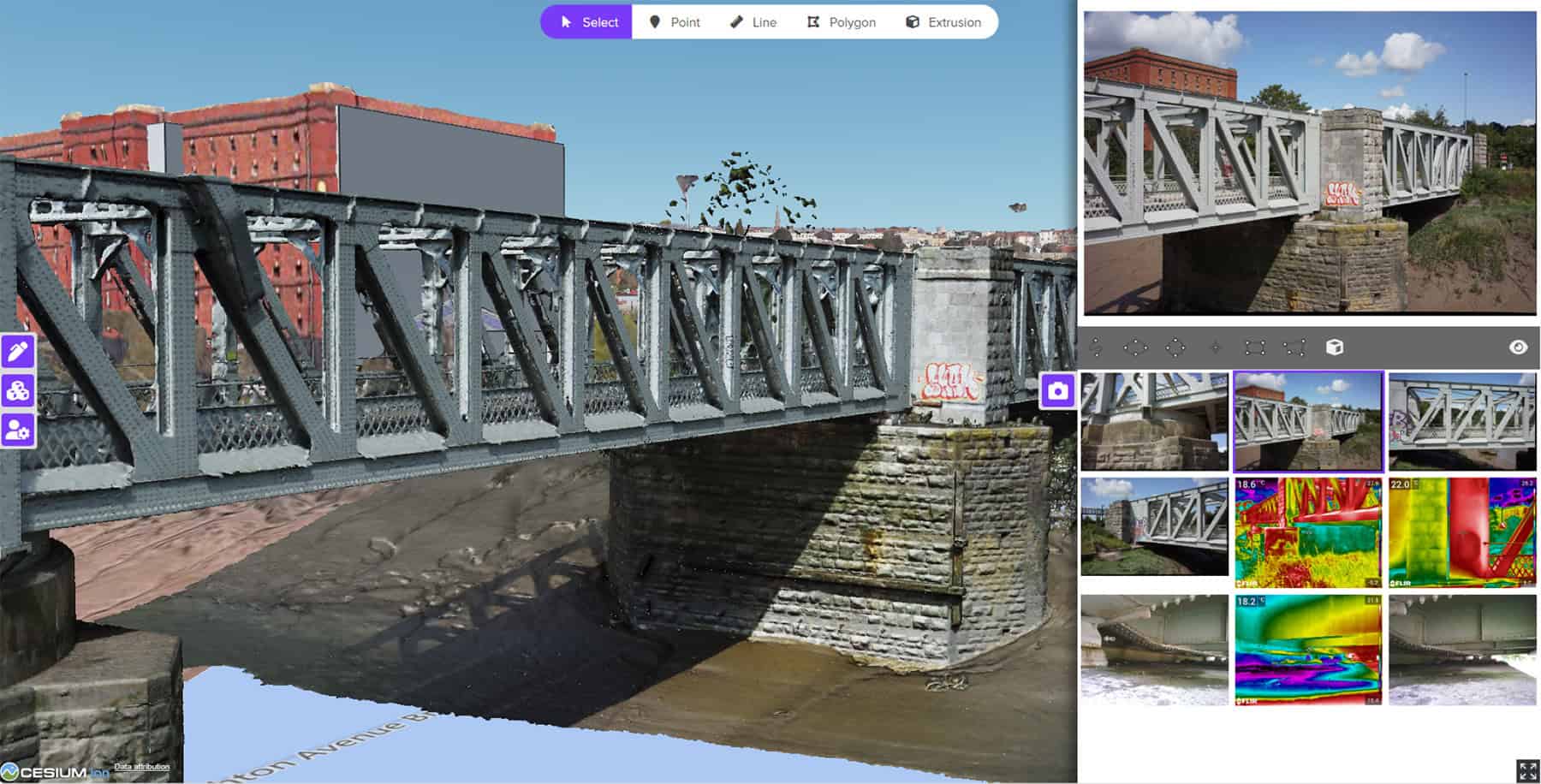

The project’s digital backbone facilitated early risk identification, regulatory compliance, and transparent stakeholder engagement. By integrating drone-based LiDAR surveys and IoT monitoring, WIKA ensured operational resilience and environmental stewardship.

Together, Bentley’s solutions enabled WIKA to meet stringent environmental, budgetary, and scheduling demands, setting a global benchmark for digitally driven, sustainable waste-to-energy infrastructure.

Outcome

Through Bentley’s integrated digital solutions, the project achieved exceptional outcomes across efficiency, sustainability, and risk mitigation. Workflows accelerated by 30%, enabling commissioning in just 10 months. Survey times dropped 70%, and rework costs fell 15%, driving major savings. SYNCHRO 4D reduced safety risks by 25% and shortened critical path activities by 12%. OpenPlant and ProStructures boosted design productivity by 40%, while ProjectWise halved document retrieval and review cycles. Design Review, part of ProjectWise, resolved over 50 clashes, and structural optimizations cut material use by 10%. IoT monitoring ensured environmental compliance, and overall efficiency gains delivered a projected 20% higher ROI than conventional methods.

The facility is expected to reduce waste transport distances by 50%, eliminate 30% of Jakarta’s daily waste, and supply a cleaner fuel alternative for industry and power generation. The project also supports job creation, enhances public health, and elevates Jakarta as a global leader in sustainable waste-to-energy innovation.

Software

Bentley AutoPipe was used to ensure the reliability of critical piping systems, supporting resilient design of the plant.

Bentley STAAD was used to develop resilient structural designs for the facility, enabling the project to withstand Jakarta’s seismic and geotechnical conditions through optimized modeling and analysis

Bentley iTwin Capture accelerated site analysis by leveraging high-accuracy drone and LiDAR surveys to provide a precise geospatial foundation for planning and execution.

Bentley iTwin IoT enabled real-time environmental monitoring and predictive maintenance for the plant, ensuring continuous operational compliance and regulatory assurance throughout the facility’s lifecycle.

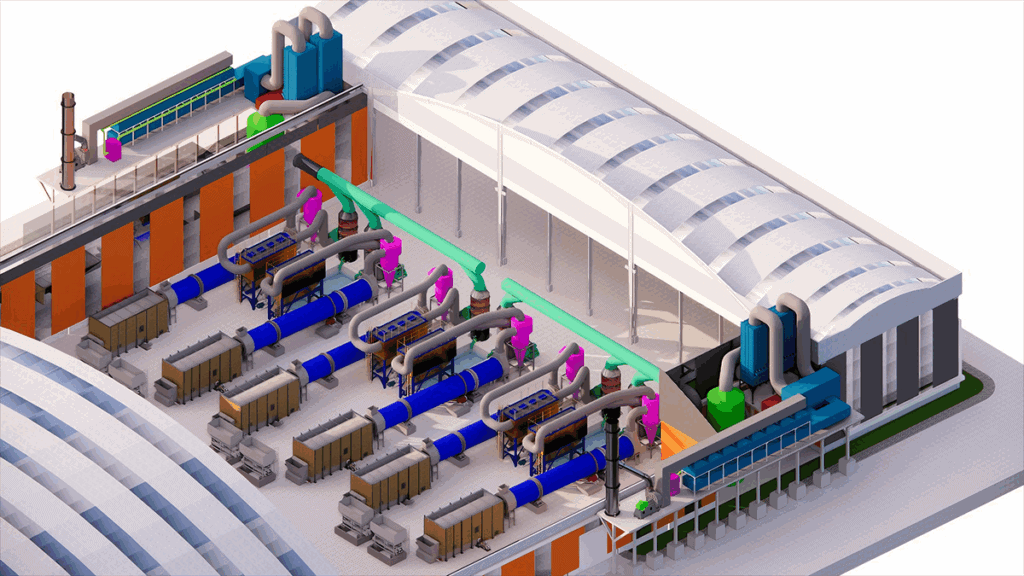

Bentley MicroStation was used to develop detailed 3D facility layouts, optimizing spatial planning for critical infrastructure components such as conveyors, bunkers, and sorting lines.

Bentley OpenPlant facilitated the modular design of complex mechanical systems, with a focus on operational efficiency and maintenance accessibility.

Bentley ProjectWise served as the project’s Common Data Environment (CDE), centralizing document management to promote seamless collaboration and reduce administrative waste throughout the delivery of the project.

Bentley ProStructures was used to efficiently model steel reinforcement and structural components, supporting optimized design and construction of the facility.

Bentley SYNCHRO enabled dynamic 4D construction sequencing for complex installations, minimizing clashes, optimizing resource deployment, and shortening the construction timeline.

Explore how Bentley software supports the energy production industry with digital construction tools that accelerate sustainable infrastructure delivery.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.