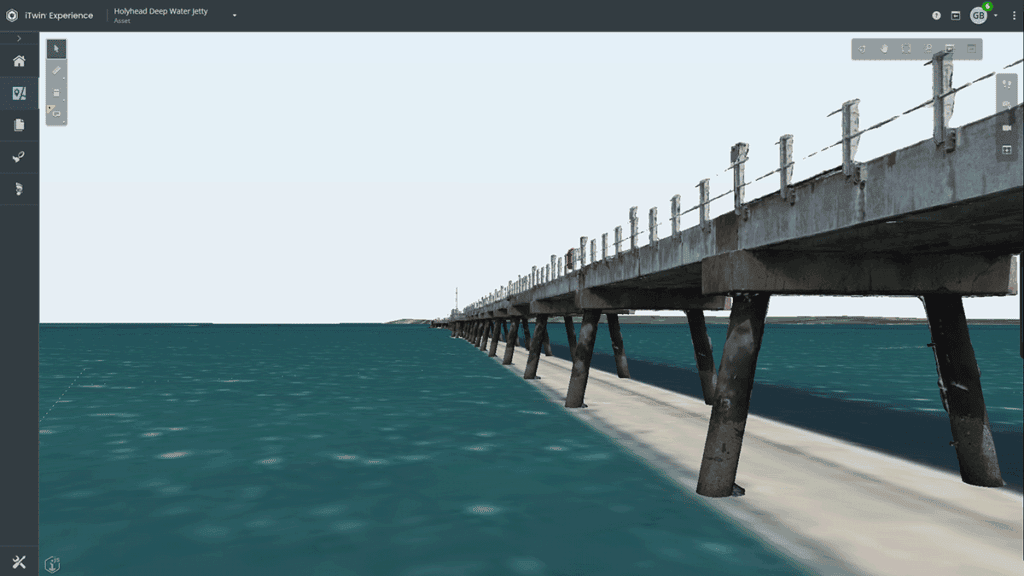

Holyhead Deepwater Jetty Inspection Project

Organization: Haskoning

Project Name: Holyhead Deepwater Jetty Inspection

Location: Holyhead, Anglesey, United Kingdom

Project Phase: Completed and Operational

Expected Completion Date: February 27, 2025

Estimated Project Cost: 110 000 GBP

Bentley Software: iTwin Capture, iTwin Experience

Project

At the Port of Holyhead in North Wales, the Deepwater Jetty is a critical berth for cruise vessels, contributing over GBP 4.75 million annually to the Welsh economy. When the aging structure required a full inspection, Haskoning was engaged by Stena Line to assess its condition and recommend necessary remediation works. With over 140 years of maritime expertise and two decades of site familiarity from their Liverpool office, the team—led by Simon Lewis, Emre Usta, Gary Barr, and Kit Chow—faced a complex challenge. The scope was extensive: 400 piles, 5 kilometers of beams, 82 crossheads, and 4,000 square meters of deck soffit. The jetty’s remote tidal location made traditional inspections costly, weather-dependent, and logistically difficult.

Beyond structural integrity, the project aimed to preserve a key maritime asset that supports tourism, local businesses, and regional development. Ensuring continued jetty operation was essential to sustaining cultural tourism, job creation, and economic resilience in North Wales. To overcome inspection constraints and align with sustainability goals, Haskoning proposed a digital-first approach—minimizing travel, fuel use, and disruption to marine habitats. The result: a smarter, safer, and more sustainable inspection that delivered technical precision and societal value.

Facts

- Faster and leaner

Achieved 60%-time savings—completed in two weeks (versus five) with just one engineer and one graduate engineer. - Remote and resilient

Enabled 24/7 virtual access, eliminated tidal/weather delays, and reduced fuel usage by 60%–75%—all with zero disruption to jetty operations. - Safer and smarter

Avoided hazardous boat-based inspections, improved defect detection via real-time 3D models and instant image retrieval. - Cost-efficient

Cut expenses by removing boat hire, coxswain fees, and long travel times—delivering broad operational savings. - Community and future-proofed

Protected jetty integrity supporting GBP 4.75 million per year in tourism, while setting a scalable precedent for high-ROI future inspections.

“Utilising Bentley software, particularly iTwin Capture and iTwin Experience, enabled remote inspections of the Holyhead Deepwater Jetty, reducing costs and environmental impact. This innovative approach enhanced accuracy, safety, and efficiency, allowing for unrestricted access without the need for physical site visits. The high-resolution 3D models facilitated detailed assessments, ensuring the jetty's continued operational capacity and supporting regional economic growth.”

- Gary Barr, Lead Digital Engineer, Haskoning

Solution

Faced with limitations in performing on-site inspections at the jetty’s exposed location, Haskoning initially tested non-Bentley mesh modeling tools. However, these lacked the resolution and clarity needed to accurately assess structural defects. After consulting their surveyor, the team pivoted to Bentley’s and for their superior image quality, interoperability, and remote accessibility.

A drone survey captured 35,000 high-resolution photographs over three days. These were processed in iTwin Capture to generate a precise 3D mesh model of the jetty. The model was then uploaded into iTwin Experience, enabling engineers and stakeholders to inspect the structure remotely via a browser-based interface—without the need for high-spec hardware. This project marked the firm’s first fully remote inspection. Previously, inspections involved boat trips, manual image review, and defect logging on paper plans. Bentley’s tools transformed that into a streamlined, desk-based workflow. Engineers could zoom into specific areas, retrieve source images, and log defects directly in the platform. Integrated reporting tools simplified documentation, while real-time access enabled collaborative review and faster decision-making.

Compared to traditional methods requiring five weeks and multiple engineers, the digital workflow completed the inspection in just two weeks with one engineer and one graduate engineer—saving 60% in time and significantly reducing labor costs. Bentley’s reality modeling and digital twin technology optimized defect identification, improved inspection accuracy, and supported scenario analysis and staff training. The remote solution also reduced carbon emissions and enhanced safety—setting a new benchmark for maritime infrastructure inspections.

Outcome

Haskoning digital inspection strategy delivered measurable impact. Site visits were eliminated, saving time, fuel, and subcontractor costs. Engineers accessed the jetty 24/7 via iTwin Experience, bypassing tidal delays and weather risks. Carbon emissions dropped by an estimated 60% to 75%, and worker safety improved dramatically. Early defect detection helped prevent potential failures, ensuring uninterrupted jetty operations. Real-time collaboration accelerated decisions and aligned disciplines. The project reinforced Haskoning’s commitment to sustainability, innovation, and community impact—delivering technical excellence while supporting economic growth and environmental stewardship in North Wales.

Software

iTwin Capture Modeler

iTwin Capture Modeler enables to automatically generate multiresolution 3D models at any scale and precision.

iTwin Experience

iTwin Experience is a cloud-based solution for infrastructure teams that unifies and visualizes data, enhances collaboration, and improves decision-making with real-time, role-specific access across systems.

Learn more about how iTwin Capture can speed up your infrastructure projects ❯

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.