Mississippi River Bridge at Lansing (Black Hawk Bridge Replacement)

Organization: Foth Infrastructure & Environment, LLC (in partnership with Parsons Corporation and Iowa Department of Transportation)

Project Name: Mississippi River Bridge at Lansing (Black Hawk Bridge Replacement)

Location: Lansing, Iowa, United States

Project Phase: Design and Construction (Digital Delivery)

Expected Completion Date: Not specified (project ongoing)

Estimated Project Cost: USD 3.2 million savings through digital delivery (total cost not specified)

Bentley Software: Bentley Descartes, Bentley LumenRT, MicroStation, OpenBridge, OpenRoads, ProjectWise, ProStructures

Additional Context: Built in 1931 and named after Chief Black Hawk, the historic bridge connects Northeast Iowa and Southwest Wisconsin across the Mississippi River. The new 1,724-foot, three-span steel truss bridge will replace the original to improve transportation safety and capacity while preserving historical significance. The Iowa DOT’s first full-scale digital delivery initiative improved collaboration, reduced schedule time by 1.5 months, and enhanced sustainability.

Project

Built in 1931 and named in honor of Chief Black Hawk of the Sauk and Fox tribes, the historic Black Hawk Bridge in Lansing has connected Northeast Iowa and Southwest Wisconsin for nearly 100 years. As the only Mississippi River crossing within 30 miles, it has been a critical transportation structure for surrounding rural communities. Now, however, it presents severe limitations for modern transportation. Recognizing this, Iowa Department of Transportation (Iowa DOT) initiated the Mississippi River Bridge at Lansing project to replace the historic bridge with a new 1,724-foot, three-span steel truss bridge that will pay homage to the original while modernizing and nearly doubling the size of the crossing.

Facts

- The digital design approach is expected to save USD 3.2 million, reduce the schedule by 1.5 months, and deliver long-term sustainability and safety benefits.

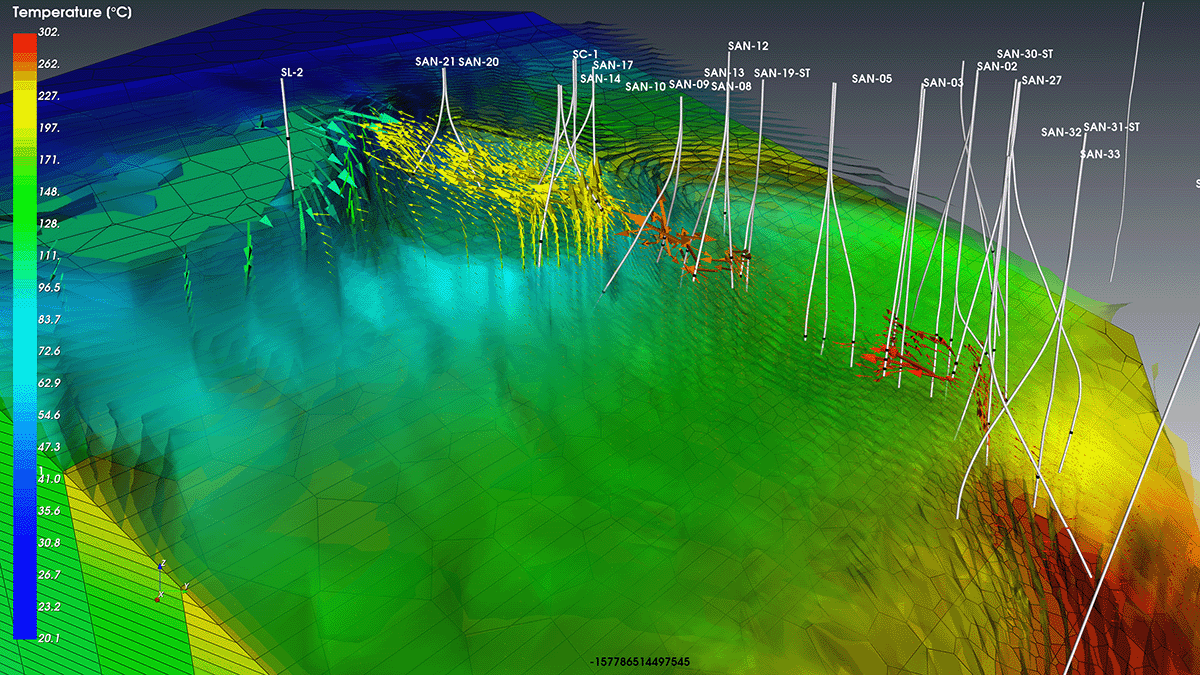

- Modeled to BIM Level of Development (LOD) 400, all 4,600 connection plates, 5,450 tons of structural steel, 28,700 shear studs, and 179,990 bolts were detailed and individually accessible within the model

- The digital model improved communication among stakeholders and the public, enabling issues to be addressed prior to construction

“The model confirmed the fit of the complex truss. Although it was intended only for informational purposes, its development validated the assembly of the intricate truss structure. Creating the model ensured proper fitment for contractors, designers, and fabricators, boosting contractor confidence and enabling more competitive bids by assuring buildability in the field.”

James Hauber, PE, Chief Structural Engineer, Bridges and Structures Bureau, Iowa DOT

Solution

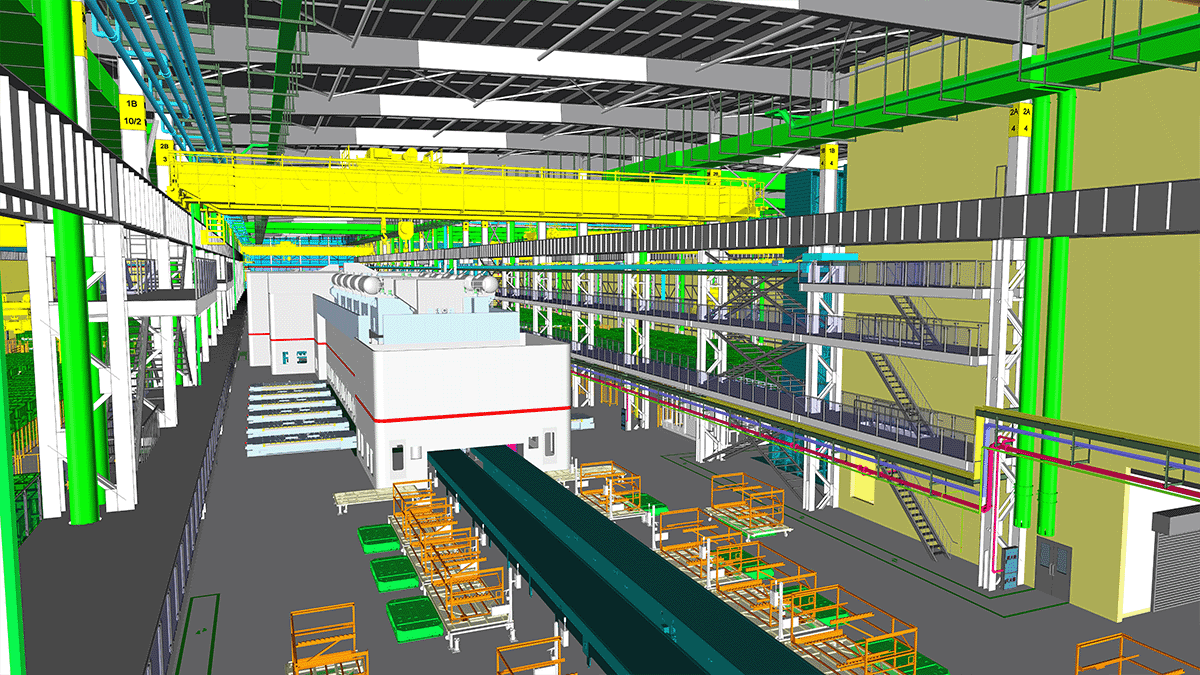

Given the project’s importance, Iowa DOT embarked upon its first full-scale digital delivery for the new bridge design. Foth Infrastructure & Environment, LLC, in partnership with Parsons Corporation, led the digital design using Bentley Infrastructure Cloud software alongside discipline-specific Bentley applications. This approach enabled advanced 3D modeling, improved collaboration, and significant efficiencies in design and construction.

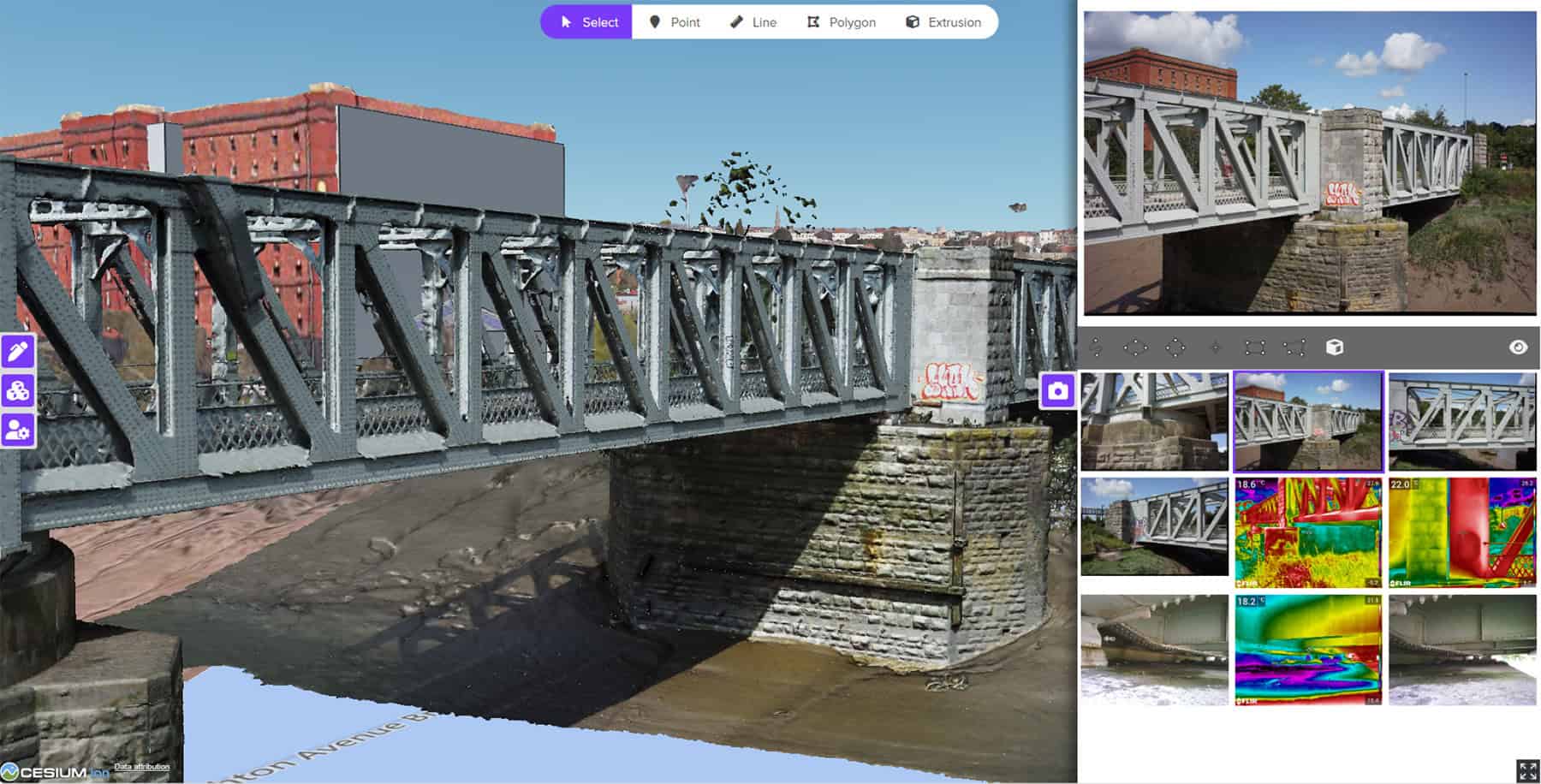

The project team created models in discipline-specific design applications including OpenBridge Modeler, OpenRoads Designer, and ProStructures. Then, using ProjectWise as a common data environment to centralize the project data, the team leveraged iTwin technology to publish a federated 3D BIM model. This digital twin was a complete, detailed representation of the bridge, including every connection plate, shear stud, and bolt.

With all their data in a single, unified environment, the project team used Bentley Infrastructure Cloud browser-based software to perform advanced workflows like clash detection, BIM data validation, and closed-loop issue resolution, which significantly reduced on-site errors, and change orders. The model provided detailed visualizations that were impossible with 2D drawings, helping fabricators identify and correct issues before construction. For instance, an issue with access holes being too small was caught and rectified early.

Bentley LumenRT and Bentley Descartes were also used to create high‑fidelity renderings and fly‑throughs. These aided in communication with contractors, community engagement, and DOT stakeholder reviews.

Outcome

The digital model was easily shared among the Iowa DOT, contractors, and the public, improving communication and stakeholder support. The ability to visualize the complex structure boosted contractor confidence, leading to more competitive bids. The team saved 200 hours of design work and 3,240 construction labor hours , along with reducing 20% of the overall estimated cost. Ultimately, this integrated digital approach directly resulted in a USD 3.2 million cost savings and reduced the project schedule by 1.5 months.

Software

Explore how ProjectWise collaboration software can streamline your digital delivery projects and improve bridge design outcomes.

Bentley Year in Infrastructure (YII) and the Going Digital Awards is an annual event where global industry leaders come together to showcase infrastructure delivery and performance excellence and exchange visionary ideas for the future. Find out more on the YII site.