At the heart of the bustling stock exchange district in Ramat Gan, construction on Israel’s tallest building is underway. Part of the “Vertical City” mega-development, the 450-meter tower will be packed with commercial, residential, and hospitality space. Yet the project’s lofty structural ambitions hinged on a much less visible milestone: the performance of the ground.

Geotechnical engineers wanted to learn more about how the ground would behave under immense loading, of 10,000 to 20,000 tons per column. So the project team constructed a 47-meter-long barrette—a kind of a reinforced steel cage—and used it to perform a ground-loading test—the first of its kind in Israel. A meticulously orchestrated trio of cranes positioned the sensor-laden barrette, and three powerful jacks applied a total of 6,000 tons of force.

The ground test results and analysis, fed into a geotechnical model in Bentley Systems’ Plaxis 3D software, gave engineers the confidence to reduce the length of foundation elements by up to 8 meters, slashed concrete use by 10%, reduced the project’s ultimate carbon footprint, and saved millions in materials.

This is what happens when deep ground insight and structural design move together. Infrastructure workflows often treat the ground, foundations, and structure as distinct phases or responsibilities, but in reality, they form a single, dynamic system where cause and effect run in every direction.

Pat McLarin

Pat McLarinWhen those elements are handled in disconnected workflows, critical feedback loops between site data and design can break down—increasing the risk of late-stage surprises. “Unanticipated ground conditions are among the top causes of claims and overruns in the industry,” says Pat McLarin, Seequent’s segment director for civil infrastructure. “The remedy isn’t more siloed thinking, but greater connection.”

Bentley Systems is uniquely positioned to support that shift, moving workflows from disconnected tasks to an end-to-end coordinated process, powered by data flowing between disciplines instead of down a chain. Bentley and Seequent—Bentley’s sub-surface company—are connecting a digital workflow that links trusted ground data, geotechnical analysis, engineering design, construction planning, and operational insights into a single digital thread.

That capability matters more now than ever, as infrastructure faces mounting pressure from urbanization, shifting transport needs, and decades of underinvestment. “The pressure to accelerate delivery is compressing delivery timelines,” McLarin says. “It means you need a tighter interaction between your geotechnical understanding and your structure, because you’re trying to evolve those things concurrently.”

The Foundation of Subsurface Data

Carl Grice

Carl GriceGround investigation is often seen as a project cost, not the critical insurance policy it truly is, says Carl Grice, who leads geotechnical data management at Seequent. “Having a good understanding of the underground is how you de-risk your project, and that starts with good data,” he says.

Site investigation data—such as boreholes, core photos, field tests, and lab results—needs to be captured, quality-checked, and instantly made available across disciplines. Everyone involved in the design process should be working from the same trusted ground model.

This is where OpenGround comes in. Seequent’s cloud platform for subsurface data management, OpenGround tracks every site test, sample, and lab result, showing exactly which boreholes informed which models and which analyses were run using them. This transparency is essential for collaboration, accountability, and learning—especially on multi-year projects.

But good data doesn’t only come from today’s investigations. The industry is waking up to the untapped value locked in decades of legacy records. “There’s a frenzy of activity across the industry,” Grice says, “to extract information from historic ground investigation reports—sometimes stored in boxes and boxes of paper.”

When done right, the payoff is substantial. For example, the U.S. Army Corps of Engineers recently used OpenGround to centralize its historical ground investigation data from 8,600 sites across the U.S., including boreholes, lab results, and cone penetration testing data. That’s roughly 2.5 million meters of exploration. The Corps now has a half-billion-dollar data asset that will enable future savings from more targeted drilling and data reuse.

“Having a good understanding of the underground is how you de-risk your project, and that starts with good data."

Carl Grice, geotechnical data management lead at Seequent

The Full Digital Thread

Historically, ground investigation was a slow, linear sequence: desk study, drill, lab tests, and then weeks or months later, modeling and analysis. Sometimes, critical insights arrived too late to optimize the design. “Even today, some geotechnical engineers are still using a notepad and pen on site, which in the era of cloud computing, I find remarkable,” Grice says.

“Cloud-connected workflows allow us to be truly iterative, rapidly using preliminary lab results to redirect test drilling to target the greatest areas of uncertainty on site,” he says. “This kind of adaptability simply didn’t exist a decade ago.”

That’s the point of the Bentley–Seequent ecosystem: to seamlessly move verified ground data through geological modeling, design, and construction, without the data loss or conservative guesswork that can arise when disciplines work in silos.

Not every project uses every Bentley tool, but the full workflow shows what’s possible. OpenGround and Leapfrog Works, the 3D ground modeling software, maintain an evolving picture of the subsurface. Plaxis, the geotechnical engineering software, and GeoStudio, for soil and rock analysis, take that model and simulate behavior—including soil–structure interaction, staged excavations, and groundwater effects. Those results inform STAAD, the structural analysis application, for structural detail. Meanwhile, SYNCHRO’s digital construction delivery software aligns the construction sequence, and iTwin, Bentley’s digital twin platform, provides a view that keeps everyone working from the same truth.

“This is a natural extension of the Building Information Modeling philosophy,” McLarin says. “By bringing different disciplines into the same environment, geotechnical and civil engineers can iterate in tighter loops.”

At Hokkaido University in Japan, for example, researchers recently created a workflow that integrates structural models from STAAD with geotechnical analysis in Plaxis, allowing them to feed structural loads directly into subsurface analysis to directly evaluate soil–structure interaction. This tight coupling of civil and geotechnical engineering capability led to a reported 90% more efficient data exchange process—the kind of rapid design validation that fast-moving infrastructure projects increasingly demand.

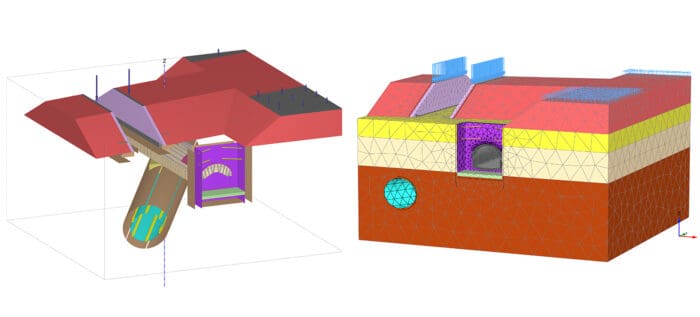

In Madrid, the Metro Line 5 extension is currently underway, costing an estimated €181 million. The extension must thread a new tunnel past an existing metro tunnel and a motorway embankment—with less than 3 meters of clearance at its tightest spot. Initially, a slower, more conservative method was proposed. But by uniting geotechnical and civil engineering in a single digital thread, engineers used Plaxis 3D to model over 400 construction stages and confidently validated a safe, more efficient approach. That deep understanding of the ground will protect Madrid’s existing infrastructure, cut costs and carbon, and keep the project on track.

Engineers used Plaxis 3D for the ground modeling and structural planning for Madrid’s Metro Line 5 project.

Engineers used Plaxis 3D for the ground modeling and structural planning for Madrid’s Metro Line 5 project.Madrid’s Metro Line 5 project shows how tightly integrated ground modeling and structural planning can unlock safer, more efficient solutions—even in complex, high-risk environments.

“Every piece of infrastructure starts with the ground. That’s always been true,” McLarin says. “What’s changing now is our ability to keep that truth connected—carrying it all the way from site investigation to design, construction, and beyond.”

For engineering teams that embrace this mindset, the payoff is more than speed or savings, Grice says. It’s clarity. “If you’ve got confidence in your subsurface analysis, then you’ve got confidence in your design—meaning you’re ultimately building better infrastructure.”

And no one is better placed to help deliver that connected future for infrastructure, from first borehole to final build, than Bentley.

Sean O’Neill is a seasoned editor, journalist, and science communicator. He spent 14 years at New Scientist and served as the magazine’s People Editor. Sean has written for Google DeepMind, served as communications lead at the Cambridge Centre for AI in Medicine at the University of Cambridge, and worked as a Science Writer for The Alan Turing Institute in London. You can also find his byline on AI stories and profiles on the Bentley blog.