On the night of January 31, 1953, a North Sea storm surge of over 5 meters inundated the Netherlands. Dikes failed. Communities disappeared under black water. Nearly 2,000 lives were lost. In the aftermath, the low-lying country faced a stark choice: outmatch the sea or risk reliving the same nightmare.

What followed was a four-decade national effort to build the Delta Works – an audacious chain of dams, sluices, levees, and storm surge barriers that redrew the map of the Rhine–Meuse–Scheldt delta. The project transformed what the Dutch, and the world, believed engineering could achieve.

The origins of PLAXIS lie within that longer story of cause and effect.

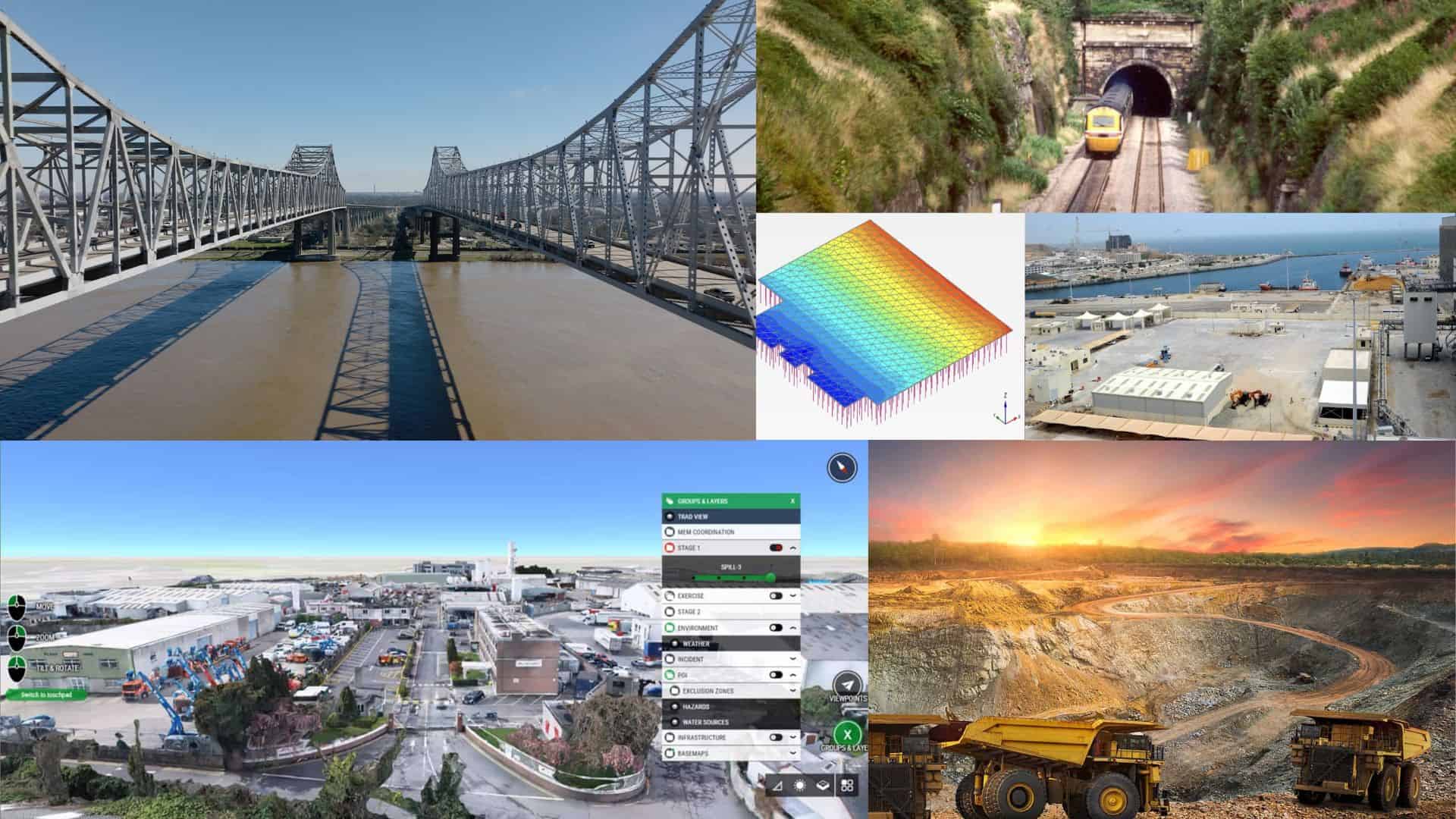

Today, engineers around the world utilize the Bentley Systems software for analyzing ground behavior, groundwater effects, and their interactions with excavations, foundations, and tunneling. PLAXIS is now used on everything from skyscraper foundations and metro tunnels to ports, mining tailings storage, offshore wind – and, of course, flood defenses. The software is trusted by engineers working in some of the most demanding geological and urban conditions, helping them predict how the ground will behave, minimize risk, and optimize design. Even universities teach with it.

Bentley, the global infrastructure engineering software company, acquired PLAXIS in 2018, bringing powerful subsurface analysis in-house to complement its existing range of above-ground capabilities for the infrastructure sector. In 2021, Bentley further expanded its subsurface portfolio by acquiring Seequent, and PLAXIS was brought into Seequent’s industry-leading subsurface software for geology, modeling, and data integration.

Many of the planet’s transport systems and most iconic buildings have relied on PLAXIS, such as Singapore’s Marina Bay Sands hotel complex, which is built on soft clay. It’s apt that in 2023, Bentley picked Marina Bay Sands to host its annual Year in Infrastructure and Going Digital Awards, an event considered the “Oscars” of infrastructure. This year, the traveling global celebration comes to PLAXIS’s hometown – Amsterdam.

Notes from the Underground

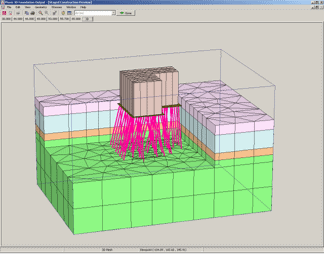

A pile foundation supporting a building, shown by an early version of Plaxis 3D Foundation, released in 2005.

A pile foundation supporting a building, shown by an early version of Plaxis 3D Foundation, released in 2005.In infrastructure design, the biggest unknowns sit below ground. The job is to identify them before they cause failure. That process begins with site investigations – boreholes, cone penetration tests, and lab analysis of soil samples. Geotechnical engineers interpret this data to derive model parameters, which they feed into PLAXIS to simulate how the ground will behave as the project takes shape.

“Mathematicians study what never happens. Physicists study what can happen. But engineers? We study what should never happen,” says Sandro Brasile, senior director of geotechnical analysis products at Seequent, now the Bentley Subsurface Company.

That’s where PLAXIS comes in. The software helps engineers model soil-structure interaction, simulate construction stages, and make designs not only safer, but leaner.

It's elementary

The story of PLAXIS begins in 1974, at Delft University of Technology, where scientists and researchers started developing a type of simulation called finite element program –just as engineers were designing a major Delta Works project, the Eastern Scheldt storm-surge barrier. Scientists used the early code to improve the barrier’s design procedures.

Finite element analysis divides complex structures into many small, connected elements. This breakdown enabled engineers to use advanced stress-strain models to simulate how soils and structures deform and share load under real-world conditions. The research effort would evolve into PLAXIS (short for PLasticity AXISymmetry).

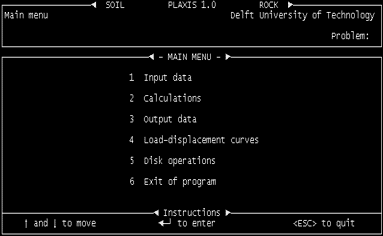

The main menu of the very first PLAXIS 2D DOS version, released in 1988.

The main menu of the very first PLAXIS 2D DOS version, released in 1988.From 1985, PLAXIS began its transformation from a university research tool into a more widely used engineering product, helped by a long-running collaboration with the Dutch Ministry of Public Works (Rijkswaterstaat).

“It started as a research tool, with applications like dike safety in mind,” recalls Ronald Brinkgreve, a key player in the early development of PLAXIS and now a distinguished scientist at Seequent. “But our goal was always to develop something practical – a tool engineers could use widely across geotechnical design and analysis.”

The Public Works Ministry pushed for a version of PLAXIS that could run on standard PCs – a key move that expanded its reach. In 1987, the first release was ready on DOS. It supported use across a growing range of problems, from retaining walls and excavations to tunnels and foundation behavior. Training courses launched soon after, and in 1993, PLAXIS spun out.

Going global, one floppy disk at a time

Brinkgreve remembers those early years as all hands to the pump. The PLAXIS developers didn’t just write the software; they packed it, shipped it, taught it, and supported it. “Each version of PLAXIS was seven or eight floppy disks, packed with a 600-page manual and a security dongle,” he says. “We were shipping these packs all over the world.” With a small team and growing global demand, the PLAXIS team sent experts to deliver training courses abroad, partnering with universities and a growing network of agents to help grow an international user community.

For years, geotechnical analysis relied on 2D cross-sections. These are effective for long, uniform structures like dikes or embankments, but in dense urban environments where tunnels, shafts, groundwater, and buildings all interact, 2D is a tougher proposition. So the introduction of an additional product, PLAXIS 3D, marked a major shift in 2010.

Engineers could now model the actual shape and phasing of complex projects, not just a series of cross-sections. That meant fewer assumptions and fewer surprises. “We spent a lot of time making our numerical procedures and constitutive models robust,” Brinkgreve says.

These models are what make finite element analysis in PLAXIS so powerful: They capture how different types of ground – soil, sand, rocks – compress, deform, or yield under load. “Our methods must work for any project worldwide, from very soft to very hard soils and rock, because we can’t anticipate the complex projects that our customers will use PLAXIS for,” Brinkgreve says.

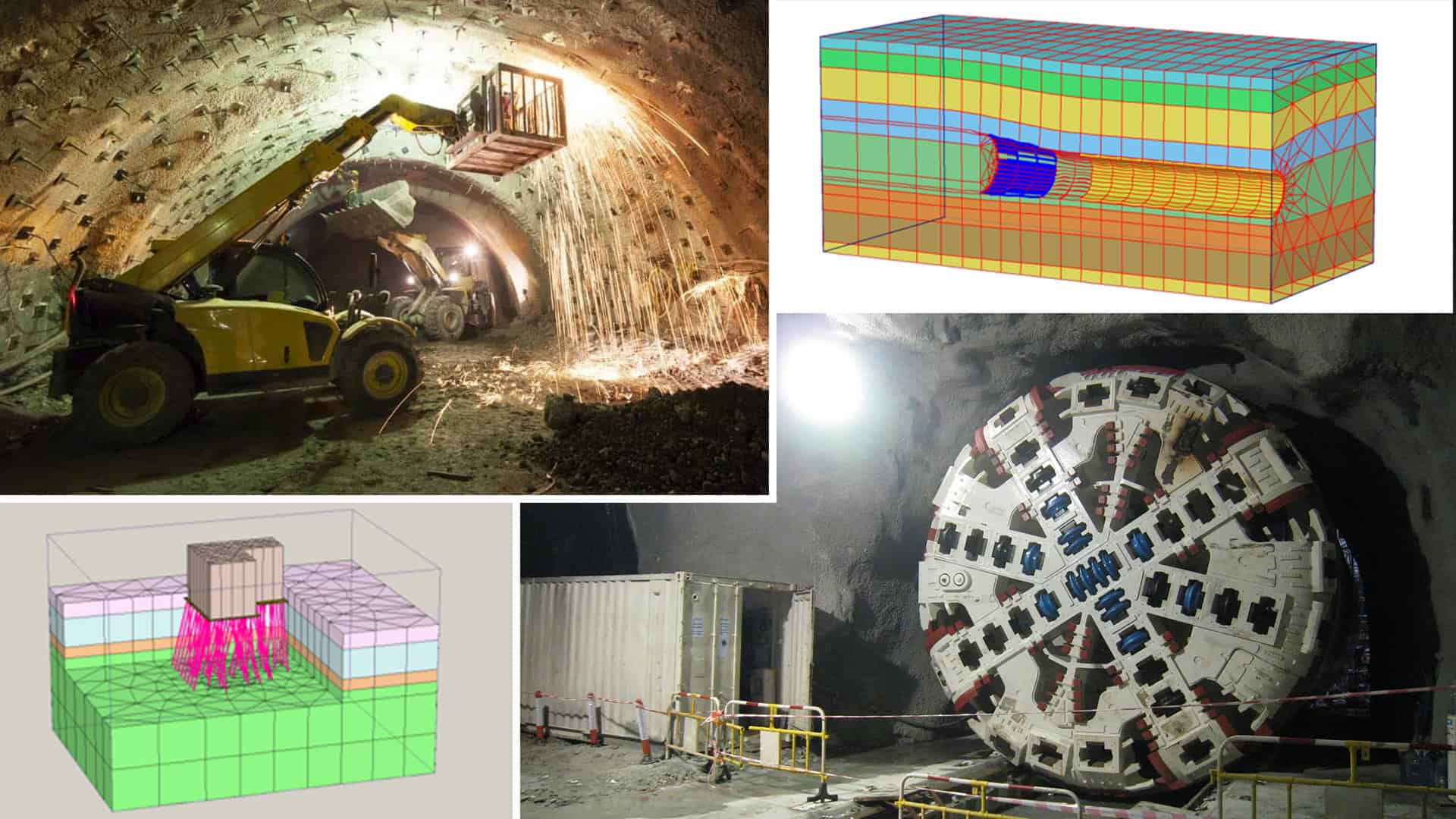

Tunnel vision

The next inflection point came in the mid-2010s, when PLAXIS introduced an API (Application Programming Interface) that allowed engineers to control the software using code. That opened the door to automation and digital integration. “If you’re designing a tunnel, for example, you often have to model dozens of identical rings,” says Brasile, the senior director at Seequent. “Before the API, you’d draw each ring manually. After, a simple Python script does it all in seconds.”

The API enabled an explosion of user creativity, Brasile recalls. “Once we opened up the API, people started using PLAXIS in ways we hadn’t even imagined. And those novel use cases regularly inspire new features for PLAXIS and deeper integrations.”

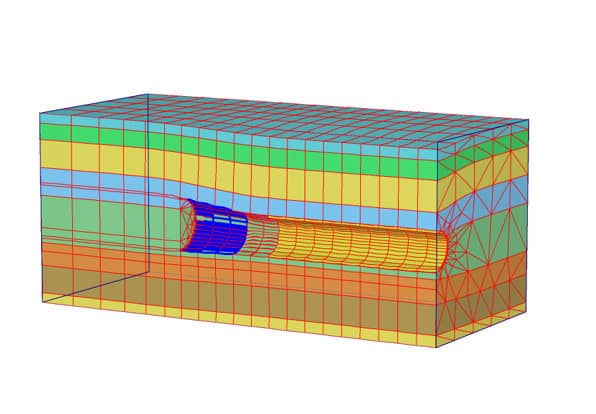

A 2001 simulation of the advancement of a TBM (tunnel boring machine) excavating a tunnel into a layered soil deposit, produced with Plaxis 3D Tunnel, released in 2000.

A 2001 simulation of the advancement of a TBM (tunnel boring machine) excavating a tunnel into a layered soil deposit, produced with Plaxis 3D Tunnel, released in 2000.Seeking ground truths

Despite its commercial growth, PLAXIS maintains connections to its academic roots, particularly university engineering departments doing fundamental research. Researchers push the theory, testing it against lab results and monitored ground behavior, while Seequent shares early features and practical know-how from the field. Once a method shows its value in the real world, it gets built into the tool. “We productize that fundamental research,” Brasile says. “It’s a win, win.”

“We use PLAXIS not only for research, but also for teaching — it really helps students and professionals speak the same language,” says Franz Tschuchnigg, a professor in Austria at Graz University of Technology’s Institute of Soil Mechanics, Foundation Engineering, and Computational Geotechnics. “For me, PLAXIS has always been more than just a piece of software. It’s a bridge between research and daily engineering practice.”

The ultimate effect of these connections is a tool with remarkable breadth and power. That capability was honored when PLAXIS won the Outstanding Innovation Award at the 20th International Conference on Soil Mechanics and Geotechnical Engineering (ICSMGE) in Sydney in 2022. The ICSMGE recognized PLAXIS for “innovations in geo-engineering that have a pronounced impact on geo-engineering practice, research, and education.” Paul Grunau, Seequent’s senior vice president of geotechnical solutions, likened the prize to a “lifetime achievement award.” But no resting on laurels followed.

In recent years, PLAXIS has helped retroactively model the interaction of the ground with a novel foundation system during the Fukushima earthquakes in Japan. PLAXIS is also enabling the safe threading of a new metro tunnel beneath live infrastructure in Madrid. It’s been used to validate the groundwork of the iconic Dallas Cowboys stadium in Texas, years after its construction. And it’s been used to cut time, cost, and carbon on Hong Kong’s deepest subsea tunnel. (Read about these ambitious projects here.)

Connecting below to above

Today, PLAXIS is a key part of Bentley and Seequent’s integrated infrastructure ecosystem: Site investigations feed into the geotechnical data management system, OpenGround; geological context is built in Leapfrog and GeoStudio; and PLAXIS runs detailed soil-structure interaction analyses. From there, results can flow into tools such as STAAD, Bentley’s infrastructure design software used to design lower Manhattan’s new floodwalls, and feed into construction and ongoing monitoring. That integration makes it possible to update PLAXIS analyses even as excavations are underway, meaning the foundation designs can be optimized in real time.

The future of geotechnical design hinges on a shift in mindset toward the Observational Method, says Brasile. “It’s a hot topic in the community. Everyone sees the value, but adoption is still low – because until recently, the digital tools just weren’t there. That’s what we’re building now.”

For example, instead of relying solely on conservative predictions made at the very start of a project, engineers can monitor how the soil behaves as excavation progresses and amend designs in real time. For deep foundations, that might mean confidently removing unnecessary steel props from the design, which saves time, money, and resources without compromising safety.

Historically, teams have worked in silos: structural engineers designed physical structures, and geotechnical engineers concerned themselves with what’s underground. When disciplines don’t fully trust each other’s assumptions, the result is conservative overdesign. “That’s how you end up with excessive foundations,” Brasile says. “Not because they’re necessarily needed, but because engineers aren’t always on the same page.”

By connecting subsurface and surface workflows, Bentley’s digital ecosystem helps teams align earlier, design only what’s needed, and cut both cost and carbon. “We’ve put so much concrete and steel in the ground. And in many cases, we’re now realizing it was unjustified,” Brasile says. “This isn’t just about cost. It’s about avoiding pollution and designing infrastructure in a way that benefits all of society.”

Back in 1953, the North Sea flood forced a nation to rethink its relationship with the sea. The response was brute-force resistance: massive barriers, reinforced dikes, and heroic feats of civil engineering. Today, engineers have new tools, including PLAXIS, that offer something different: the ability to confidently predict how the ground will behave and build only what is truly needed. The goal is no longer to outmatch nature with pure strength, but to deeply understand it – and design accordingly.

Sean O’Neill is a seasoned editor, journalist, and science communicator. He spent 14 years at New Scientist and served as the magazine’s People Editor. Sean has written for Google DeepMind, served as communications lead at the Cambridge Centre for AI in Medicine at the University of Cambridge, and worked as a Science Writer for The Alan Turing Institute in London. You can also find his byline on AI stories and profiles on the Bentley blog.